Short-process flexible drill rod producing equipment and process

A technology of production equipment and production process, which is applied in the field of short-flow flexible drill pipe production equipment and its production process, which can solve the problems of slow process tempo, poor controllability of welding surface quality, and iron filings, so as to improve production tempo , improve the appearance quality, and improve the effect of equipment configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

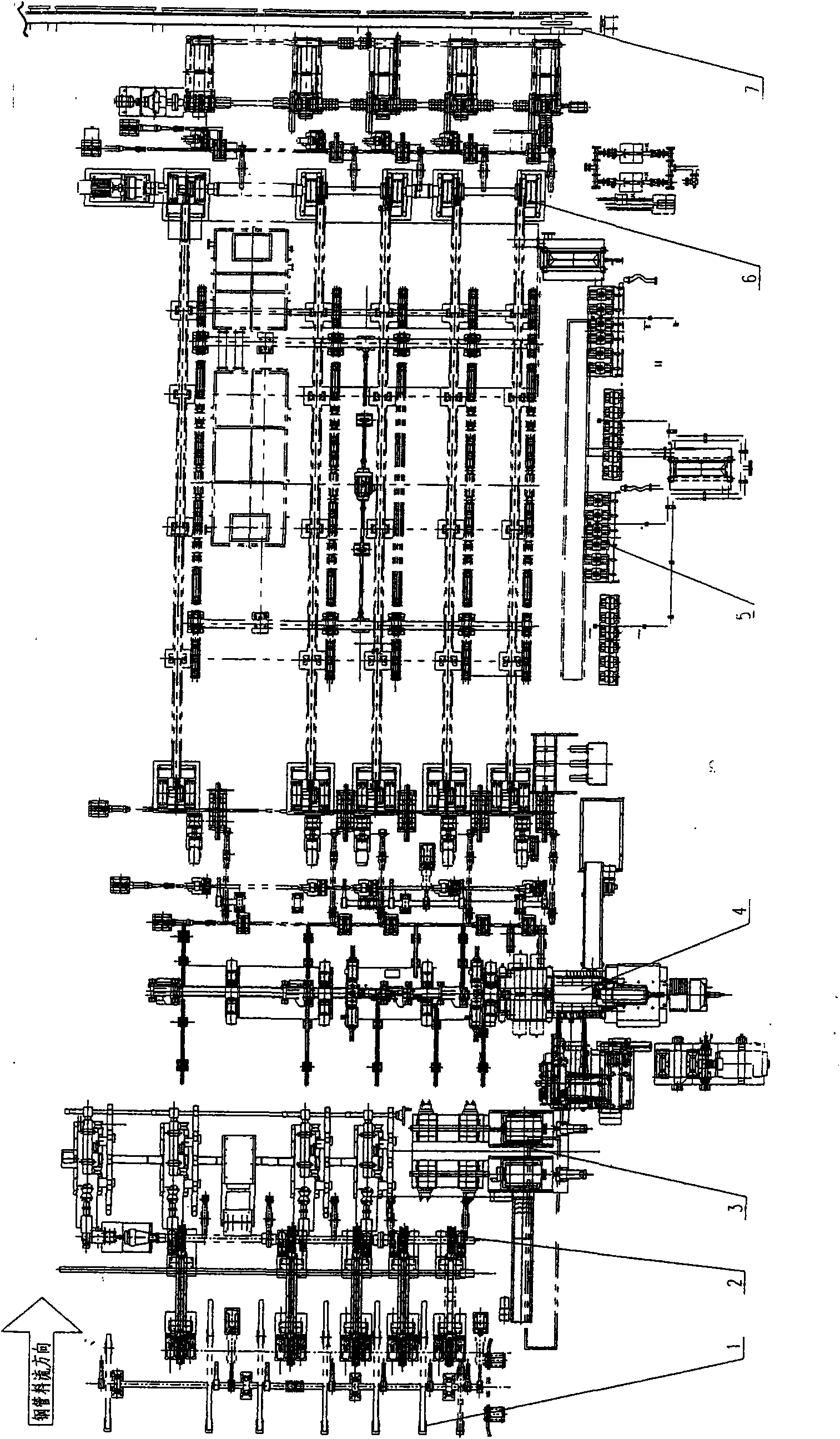

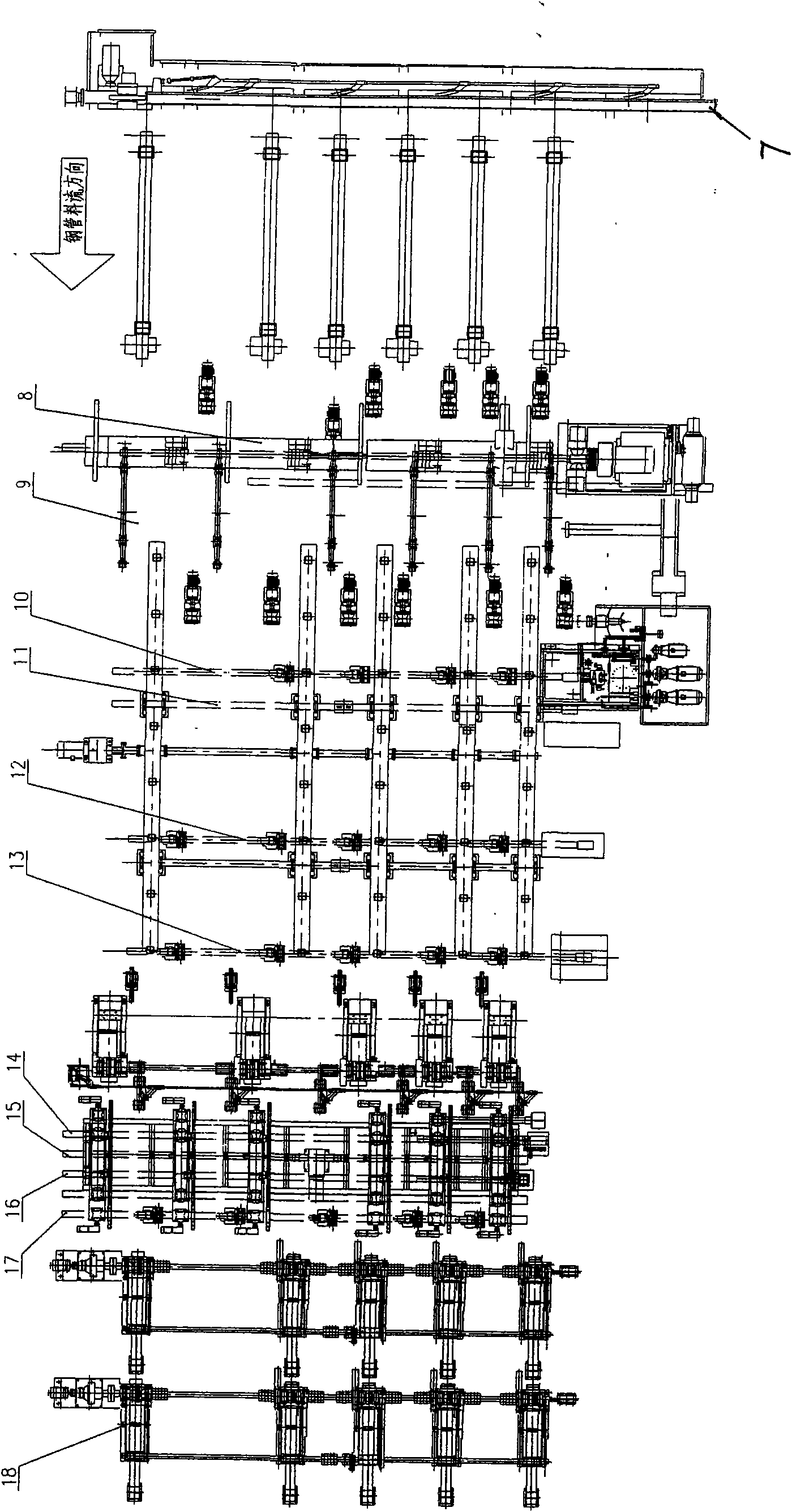

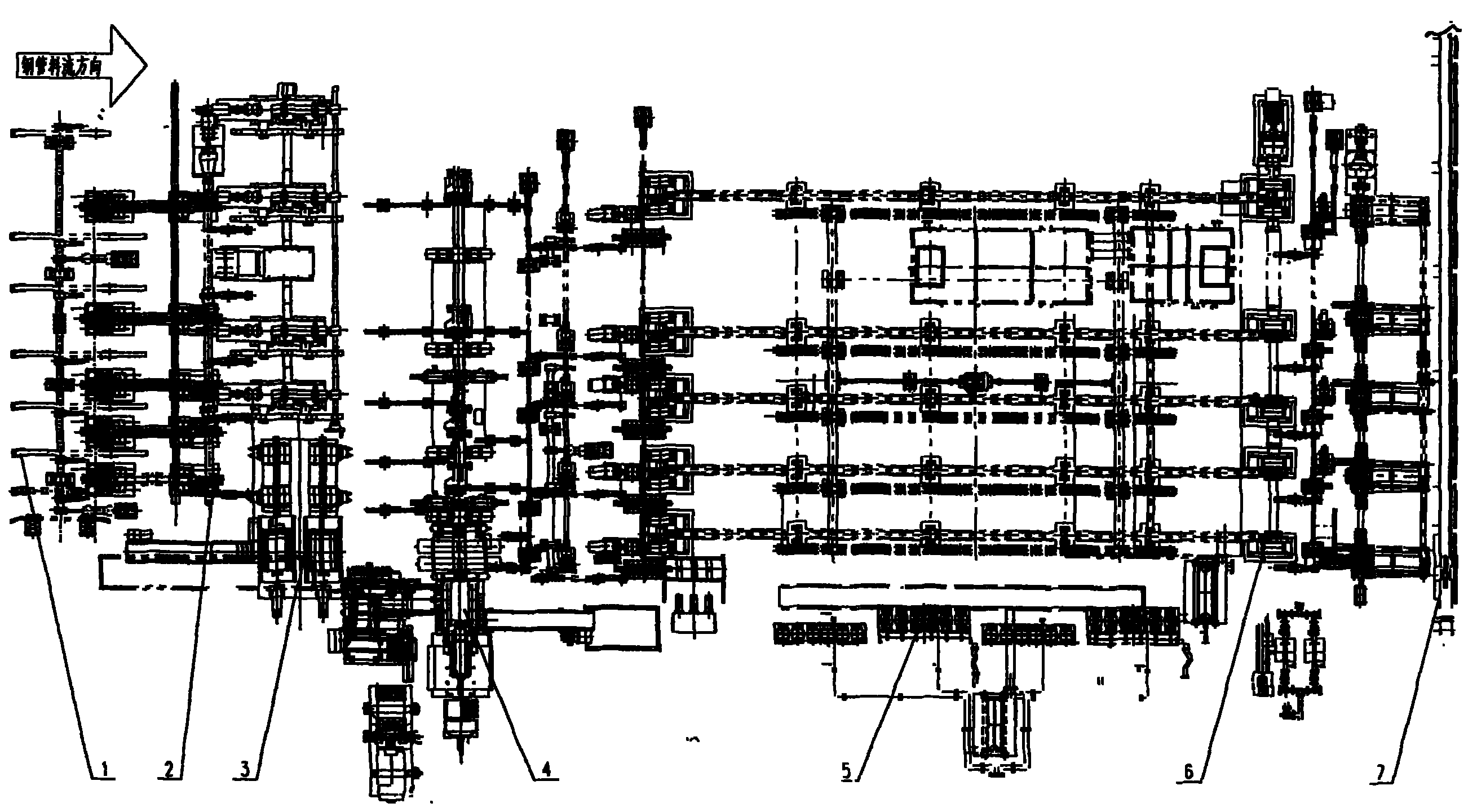

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail, figure 1 and figure 2 They are connected by vertical transport chain 7.

[0015] A short-process flexible drill pipe production equipment, including a feeding platform 1, characterized in that the feeding platform 1 is connected to a pipe end processing machine tool 3 through a roller conveyor chain 2, and the rear end of the pipe end processing machine tool 3 is provided with Friction welding machine tool 4, the rear end of friction welding machine tool 4 is provided with weld seam heat treatment device 5, weld seam heat treatment device 5 is connected with weld seam finishing machine tool 8 through conveying device, and weld seam finishing machine tool 8 rear end is provided with iron The chip suction device 9 and iron chip suction device 9 are provided with various inspection devices at the rear end, and the finished product frame 18 is provided at the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com