Immune feed additive and preparation method thereof

A feed additive and scrap technology, which is applied in the field of feed industry and aquaculture, can solve the problems of high feeding cost of fly maggots, excessive heavy metals, low digestion and absorption rate of fly maggot protein, etc. Glossy and immune-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

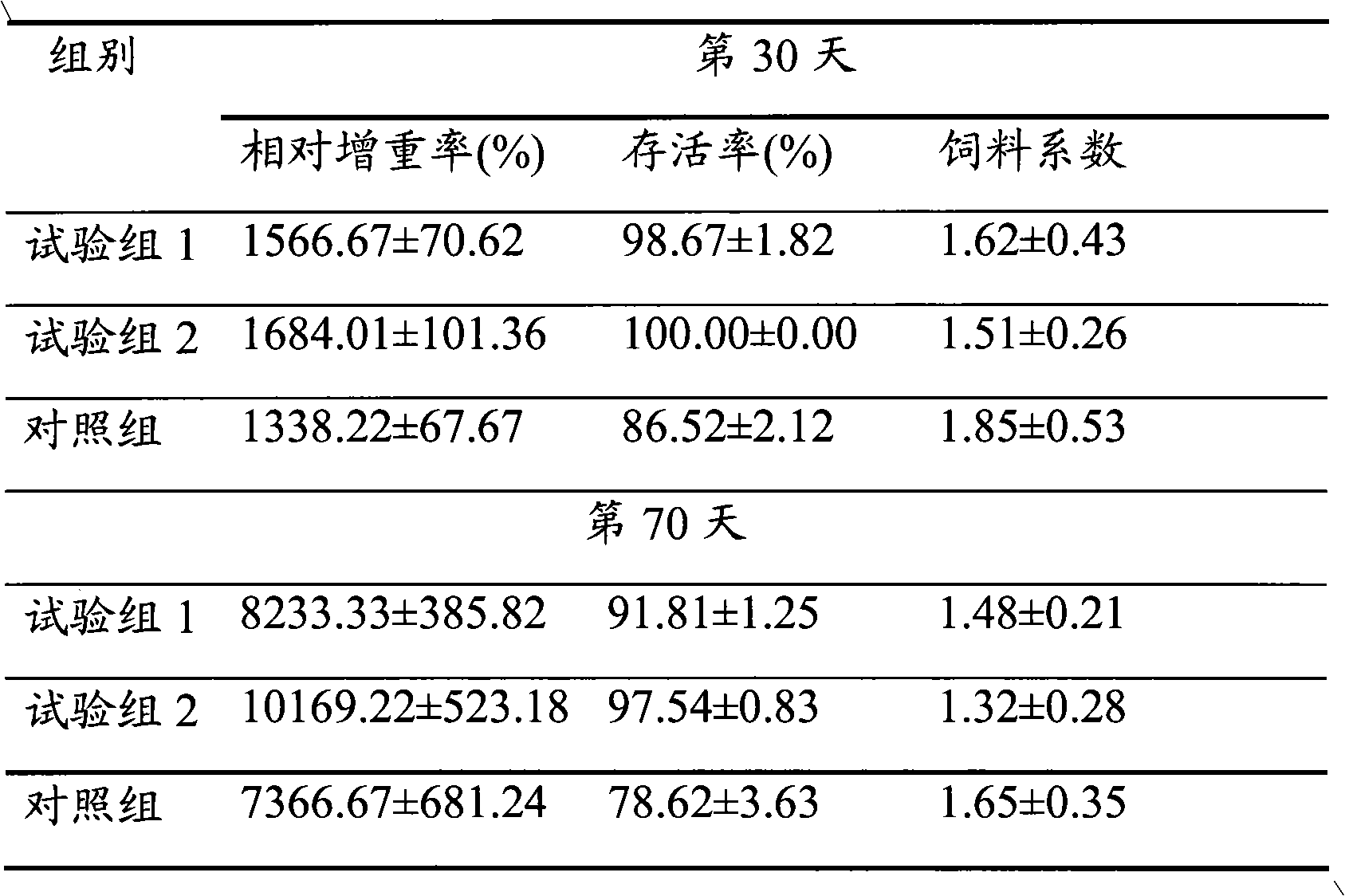

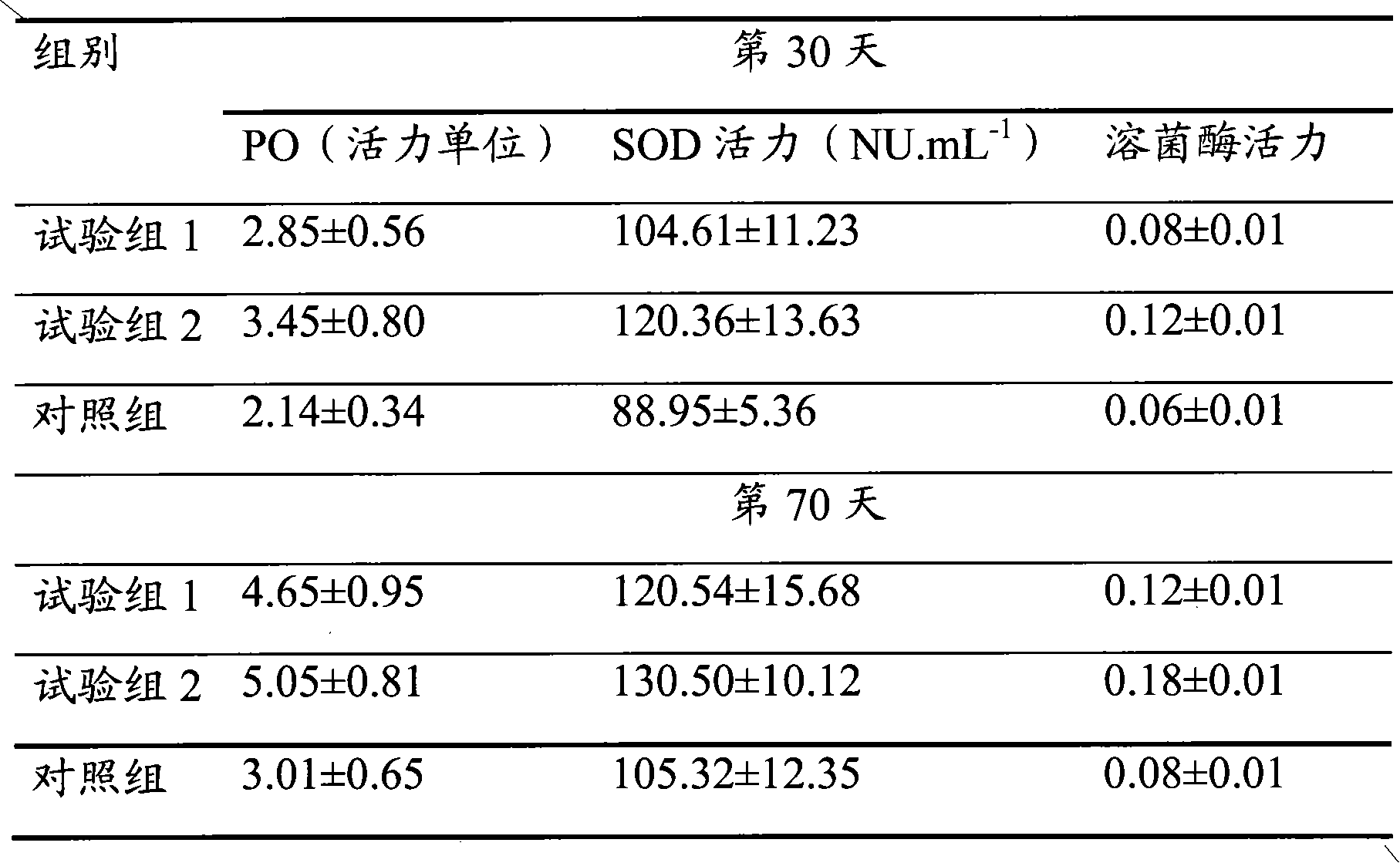

Examples

Embodiment 1

[0040] Example 1: Preparation of Feed Additives Using Shrimp Processing Waste to Raise Fly Maggots

[0041] (1) Take 1 ton of fresh shrimp processing waste, crush it into 60 meshes, then carry out conventional sterilization, fully mix the raw materials and water in a ratio of 5:1 by weight, insert 7% of the rejuvenated composite bacteria, The composite bacteria are Lactobacillus acidophilus, Saccharomyces cerevisiae and Bacillus subtilis with a weight ratio of 1:1:1. At the same time, 60 kg of molasses is added and stirred evenly. hour, the fermented material is baked to semi-dry and wet (advisable with humidity 60%~65%), and the actual fly maggot food is about 600 kilograms;

[0042] (2) put into 6 centimeters of thick fly maggot food earlier in the fly maggot pool, mix 1g fly ovum ratio by 1kg food material, at humidity 65%, cultivate 3 days under 32 ℃ of temperature, fly maggot is separated with compost, can Obtain about 380 kg of fly maggots;

[0043] (3) Place the isola...

Embodiment 2

[0045] Embodiment 2: Making use of tilapia processing leftovers to raise fly maggots to prepare feed additives

[0046] (1) Take 1 ton of fresh tilapia processing waste, crush it into 80 meshes, and then carry out conventional sterilization, fully mix the raw materials and water in a ratio of 5:1 by weight, and insert 5% rejuvenated compound Bacteria, the composite bacteria are Lactobacillus acidophilus, Saccharomyces cerevisiae and Bacillus subtilis with a weight ratio of 1:1:1. At the same time, add 60 kg of molasses and stir evenly. After adjusting the pH to 6.0, place it in a constant temperature fermentation tank at 30°C Ferment for 52 hours, bake the fermented material to a semi-dry and wet state (preferably with a humidity of 60% to 65%), and obtain about 600 kg of actual fly maggot food;

[0047] (2) put into 4 centimeters of thick fly maggot food material earlier in the fly maggot pool, mix 1g fly ovum ratio by 1kg food material, at humidity 70%, cultivate 4 days unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com