TMR (total mixed ration) fermented feed taking rice grass as raw material for replacement dairy cows and preparation method thereof

A fermented feed and rice grass technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problem of corn harvesting, cutting, short storage and processing time, affecting the growth and development of heifers, affecting the feeding effect of silage corn, etc. problems, to achieve the effect of increasing utilization rate and feeding effect, increasing the nutritional value of feed, and alleviating the ecological environment crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

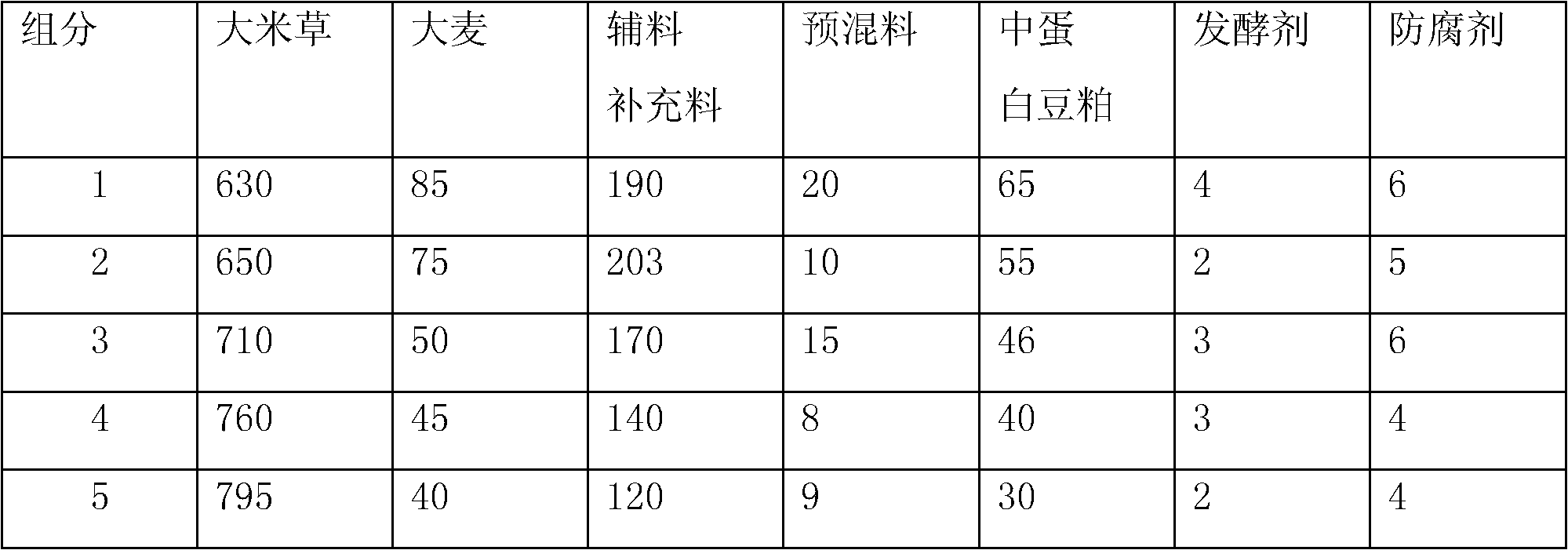

[0048]

[0049] Add the components in the above-mentioned fermented feed materials 1-5 into the TMR mixer and mix evenly, then add water to the fermented raw materials in the mixer, and adjust the water to 45%-55% of the total mass of the feed; Put it into a polyethylene film vacuum bag, and reach the required density after vacuuming (500-800 kg / m 3 ), and the bag is sealed and finished; after 10-80 days of fermentation, it can be fed to back cattle.

[0050] Each group of raw materials in the above-mentioned embodiment is feed grade, and is conventional commercially available product, and information is as follows:

[0051] Spartina: Harvested in tidal flats in coastal areas

[0052] Barley: Shanghai Dingniu Feed Co., Ltd.

[0053] Premix: Shanghai Dingniu Feed Co., Ltd.

[0054] Medium protein soybean meal: Shanghai Dingniu Feed Co., Ltd.

[0055] Fermentation agent: French Laman company

[0056] Antifungal agent: Shanghai Luyuan Fine Chemical Co., Ltd.

Embodiment 2

[0058] Add the components of the first fermented feed material in Example 1 into a TMR mixer and mix evenly, then add water to the fermented material in the mixer, and adjust the water content to 45%-55% of the total mass of the feed; Fill the feed into the polyethylene film vacuum bag, and reach the required density after vacuuming (500-800 kg / m 3 ), finished after the bag was sealed; fermented for 15 days.

[0059] Laboratory analysis: the same batch of feed samples were sampled reasonably for the 0-day-fermented Spartina mixed feed and the 15-day-fermented Spartina mixed-fermented TMR feed to detect the contents of dry matter, crude protein, crude fat, ADF, NDF and crude ash .

[0060] All detected raw data were statistically analyzed by SPSS17.0. The test results showed that the dry matter of the mixed Spartina fermented feed fermented for 15 days was reduced by 0.91%, the crude protein increased by 0.25%, the crude fat significantly increased by 0.29%, the ADF significa...

Embodiment 3

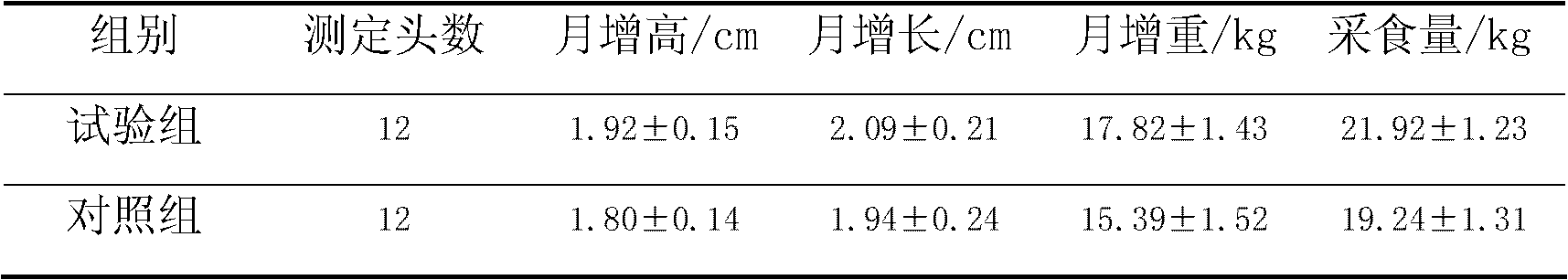

[0062] The 6-month-old calves in the pasture were measured for their height, body length, chest circumference, and weight indicators. From these dairy cows, cows with similar data were selected for pairing and grouping. A total of 16 eligible 6-month-old calves were selected. The cows were used as the test group and the control group (8 cows in each group), and the calves had free access to water and food. The two groups of cows were placed on the east and west sides of the same ring barn environment.

[0063] Test method: Both the test group and the control group used Example 2, the control group was fed the feed that was not fermented in Example 2, and the test control group was fed the feed that was fermented in Example 2 for 20 days. During the experiment, regular and quantitative feeding was performed, 3 times during the day, and once at night, and the remaining feed was cleaned up the next day. On the last day of the experiment (the 40th day), the bust, body height, body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com