Method for removing impurities on surface of metal silicon

A metal silicon and impurity technology, applied in the direction of non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of large equipment investment and large power consumption, and achieve low energy consumption, small investment, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

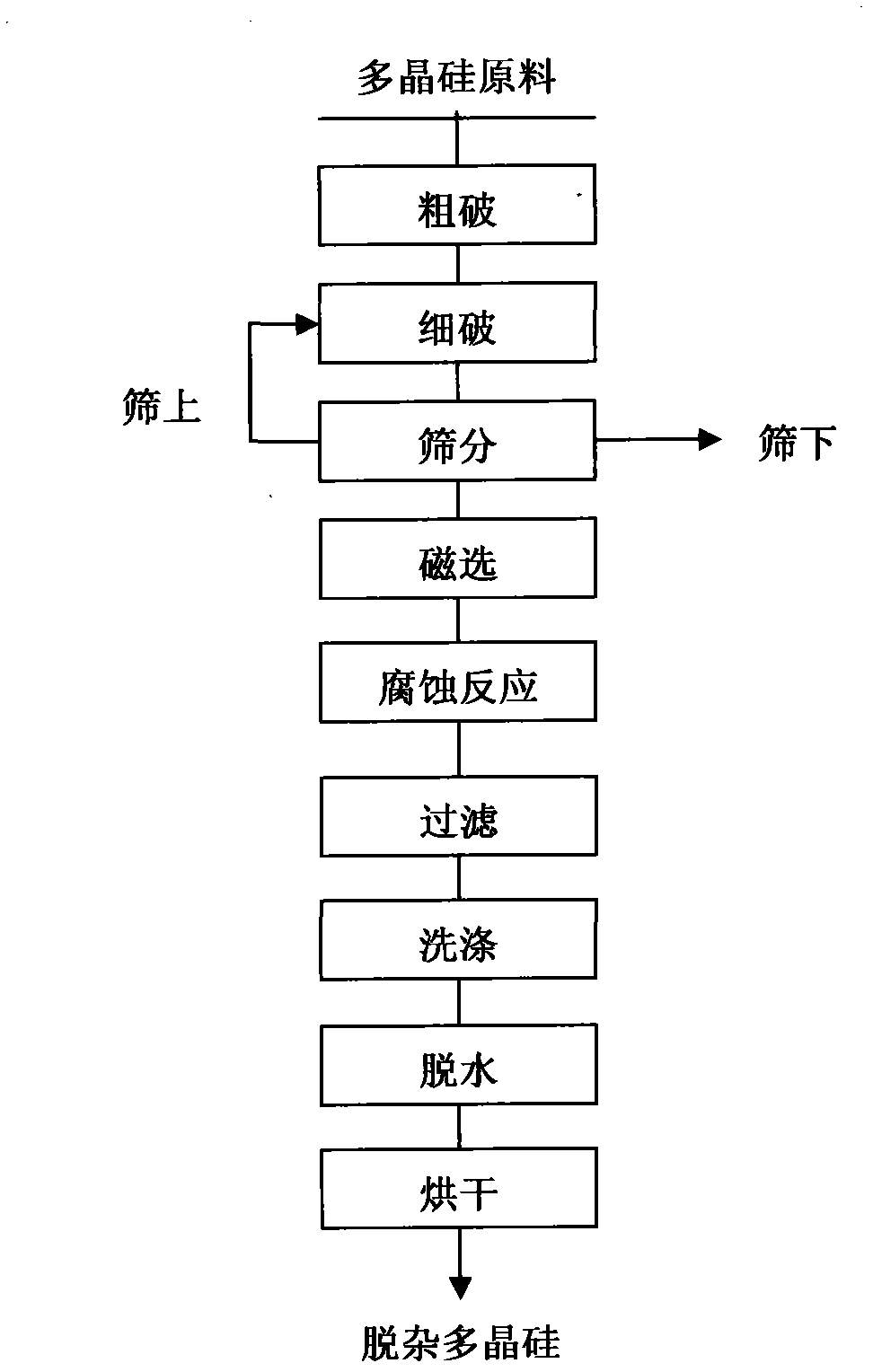

Method used

Image

Examples

Embodiment 1

[0038]1. The chemical composition of metal silicon ore is as follows (unit ppmw): Li0.07, Na0.04, Mg0.14, Al395, Ca15, Sc0.08, Ti86, V80, Cr4.2, Mn32, Fe697, Co4.1, Ni176, Cu8.5, Ge3.3, As0.04, Sr0.03, Y0.07, Zr1.8, Nb0.26, Mo6.7, Ba0.03, La1.8, Ce2.6, Pr0.5, Nd0.87, Sm0.04, Gd0.45, Tb0.05, Dy0.34, Ho0.03, Er0.23, Tm0.02, Yb0.007, Lu0.009, W1.8, Th0.20, U0. 13, that is: the total amount of impurities, that is, TM is 1441.3.

[0039] 2. Process conditions: Metal silicon raw materials are coarsely crushed to -3mm, and finely crushed to -40+200 mesh material is greater than 95%, sieved into three grades of +40 mesh, -40+200 mesh, and -200 mesh. Among them, +40 mesh returns to fine crushing, and the intermediate particle size enters wet magnetic separation. The concentration of the magnetic separation pulp is 35% to 40%, and the magnetic field strength is 12000 to 14000Oe. Corrosive agent, heated to 50 ° C, stirred for 8 hours. After the completion of filtration, the filtrate i...

Embodiment 2

[0041] 1. The chemical composition of metal silicon ore is as follows (unit ppmw): Li0.07, Na0.04, Mg0.14, Al395, Ca15, Sc0.08, Ti86, V80, Cr4.2, Mn32, Fe697, Co4.1, Ni176, Cu8.5, Ge3.3, As0.04, Sr0.03, Y0.07, Zr1.8, Nb0.26, Mo6.7, Ba0.03, La1.8, Ce2.6, Pr0.5, Nd0.87, Sm0.04, Gd0.45, Tb0.05, Dy0.34, Ho0.03, Er0.23, Tm0.02, Yb0.007, Lu0.009, W1.8, Th0.20, U0. 13, namely: TM is 1441.3.

[0042] 2. Process conditions: Metal silicon raw materials are coarsely crushed to -3mm, and finely crushed to -40+200 mesh material is greater than 95%, sieved into three grades of +40 mesh, -40+200 mesh, and -200 mesh. Among them, +40 mesh returns to fine crushing, and the intermediate particle size enters wet magnetic separation. The concentration of the magnetic separation pulp is 35% to 40%, and the magnetic field strength is 12000 to 14000Oe. Corrosive agent, heated to 60 ° C, stirred for 10 hours. After the completion of filtration, the filtrate is recycled, and the filter cake is washe...

Embodiment 3

[0044] 1. The chemical composition of metal silicon ore is as follows (unit ppmw): Li0.07, Na0.04, Mg0.14, Al395, Ca15, Sc0.08, Ti86, V80, Cr4.2, Mn32, Fe697, Co4.1, Ni176, Cu8.5, Ge3.3, As0.04, Sr0.03, Y0.07, Zr1.8, Nb0.26, Mo6.7, Ba0.03, La1.8, Ce2.6, Pr0.5, Nd0.87, Sm0.04, Gd0.45, Tb0.05, Dy0.34, Ho0.03, Er0.23, Tm0.02, Yb0.007, Lu0.009, W1.8, Th0.20, U0. 13, namely: TM is 1441.3.

[0045] 2. Process conditions: Metal silicon raw materials are coarsely crushed to -3mm, and finely crushed to -40+200 mesh material is greater than 95%, sieved into three grades of +40 mesh, -40+200 mesh, and -200 mesh. Among them, +40 mesh returns to fine crushing, and the intermediate particle size enters dry magnetic separation. After the magnetic field strength is 14000Oe, put it into a container with stirring, add a composite corrosive agent with a concentration of 20%, heat it to 80°C, and stir for 12 hours. After the completion of filtration, the filtrate is recycled, and the filter cak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com