Hyperbranched polymer, hyperbranched type water reducing agent of polycarboxylic acid series and preparation method and application thereof

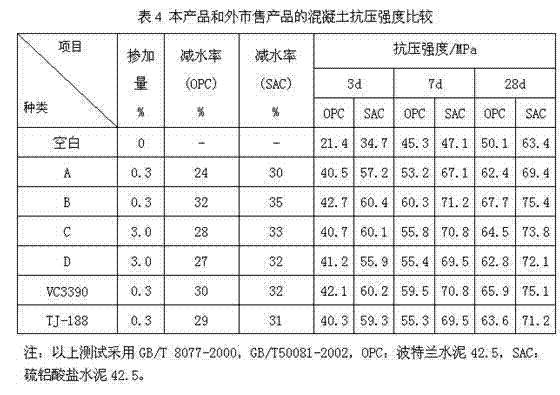

A technology of hyperbranched polymer and hyperbranched polymer, which is applied in the field of hyperbranched polymer and hyperbranched carboxylic acid-based water reducing agent, can solve the problems of poor cement adaptability, low water reducing rate and the like, and achieves Superior performance, strong frost resistance and high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

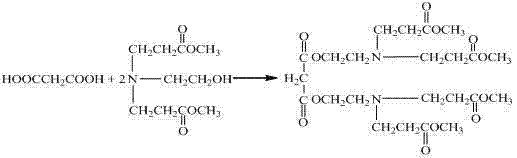

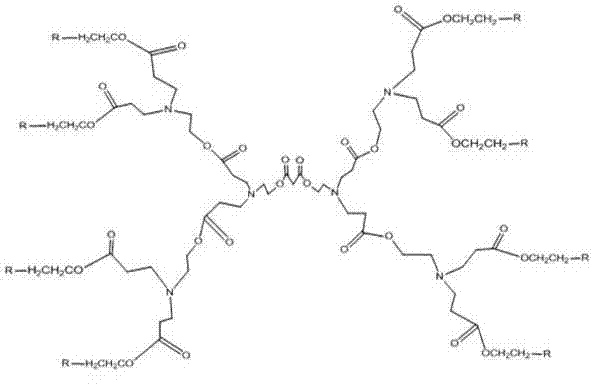

[0051] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, stir the mixture at room temperature for 30min and then heat up to 40°C for 10h , and then the methanol was removed by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 7 h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-dipropionate methyl ester monomer and 0.04g of p-phenyl...

Embodiment 2

[0053] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser tube, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, and the mixture is stirred at room temperature and nitrogen for 20-30min and then heated to 40- Keep at 50°C for 8-10h, then remove the methanol by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 5-7h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-methyl dipropionate ...

Embodiment 3

[0055] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, stir the mixture at room temperature for 30min and then heat up to 40°C for 10h , and then the methanol was removed by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 7 h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-dipropionate methyl ester monomer and 0.04g of p-phenyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com