Method for leaching vegetable fat with dimethly carbonate

A technology of dimethyl carbonate and vegetable oil, applied in the direction of oil/fat production, fat production, etc., can solve the problems of solvent residue, nervous system toxicity, etc., and achieve the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

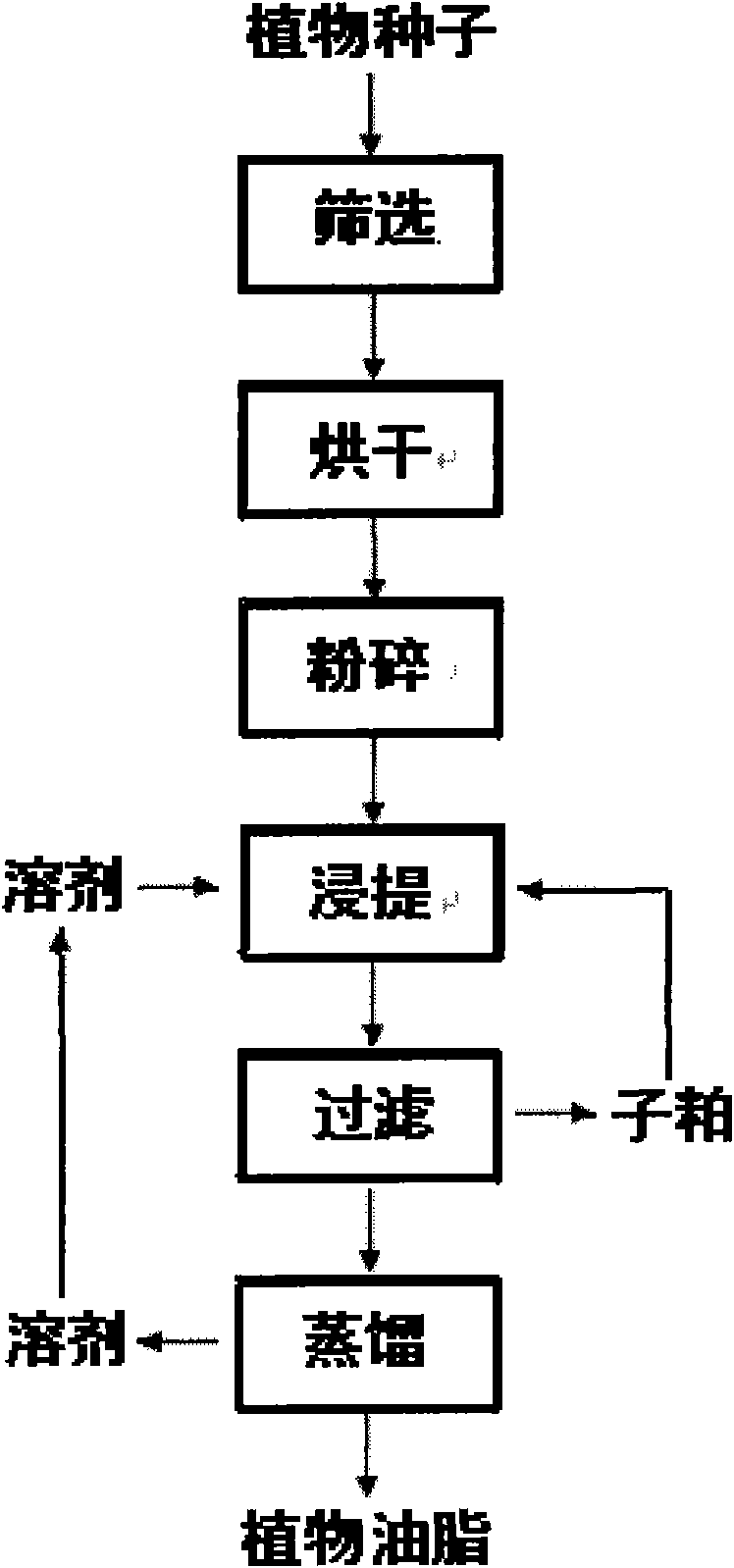

Image

Examples

Embodiment 1

[0028]Take 500 parts by weight of commercially available soybeans, sieve out impurities such as sand, dry them until the water content is within 13-15% by weight, pulverize them on a pulverizer, pass through a 20-mesh sieve, put them into an extraction tank, and add 1800 parts by weight of carbonic acid Dimethyl ester (DMC) solvent, leaching at 70°C for 60 minutes, standing for 10 minutes, filtering and separating the mixed oil and seed meal, distilling the mixed oil under reduced pressure under the protection of nitrogen, recovering the solvent and collecting soybean oil; adding the seed meal to Dimethyl carbonate (DMC) 1800 weight parts, repeat above-mentioned leaching operation 2 times, once leaching oil extraction rate is 75.2%, after three leaching oil extraction rates are altogether 96.8%, gained leaching soybean oil is light yellow clear solution ,odorless.

Embodiment 2

[0030] Take commercially available fresh camellia oleifera fruit, remove the shell and separate the tea seeds, dry them naturally in the sun, screen out impurities such as sand, take 500 parts by weight to remove the tea seed shells, and dry the tea seed kernels until the moisture content is 12-2. Within 14% weight ratio, pulverize on a pulverizer, pass through a 40-mesh sieve, add 1000 parts by weight of dimethyl carbonate (DMC) solvent, extract at 65°C for 90 minutes, leave it for 10 minutes, filter and separate the mixed oil and seed meal, and The mixed oil was distilled under reduced pressure under the protection of nitrogen, the solvent was recovered and the tea seed oil was collected; 1000 parts by weight of dimethyl carbonate (DMC) was added to the seed meal, and the above extraction operation was repeated twice, and the oil extraction rate of one extraction was 86.3 %, the oil extraction rate after three extractions is 97.6% in total, and the obtained extracted tea seed...

Embodiment 3

[0032] Commercially available dry peanuts are sieved to remove impurities such as sand, shelled, and 500 parts by weight are taken, dried until the water content is within the weight ratio of 13-15%, crushed on a grinder, passed through a 40-mesh sieve, put into an extraction tank, and added 1500 parts by weight of dimethyl carbonate (DMC) solvent, leaching at 75°C for 80min, after standing for 10min, filtering and separating the mixed oil and seed meal, the mixed oil is distilled under reduced pressure under the protection of nitrogen, reclaiming the solvent and collecting peanut oil; Add 1500 parts by weight of dimethyl carbonate (DMC) to the seed meal again, repeat the above-mentioned leaching operation 2 times, and the oil extraction rate of one extraction is 73.8%, and the oil extraction rate after three extractions is 95.6% altogether, and the gained extraction peanut oil is Light yellow clear solution, no peculiar smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com