Strontium-base bulk metallic glass and preparation method thereof

A technology of bulk metal and glass, which is applied in the field of condensed matter physics and material science, can solve the problems of large elastic limit and low elastic modulus, and achieve the effect of simple composition, simple preparation method and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

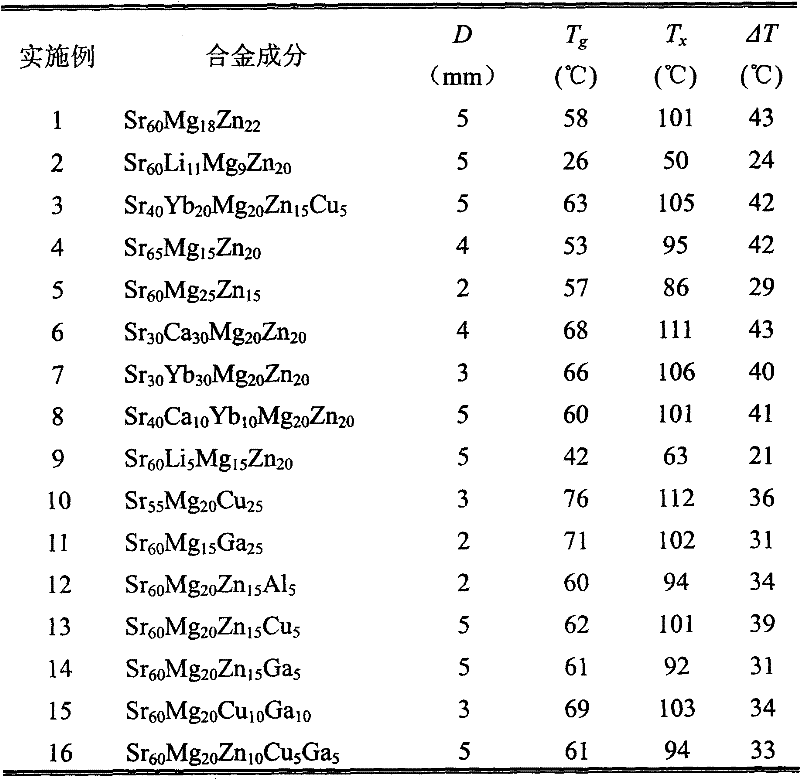

[0019] Example 1, Sr 60 Mg 18 Zn 22 Preparation of strontium-based bulk metallic glasses

[0020] The three components of strontium with a raw material purity of 99wt% and 99.9wt% magnesium and zinc are prepared in a molar ratio of 60:18:22 and then put into a quartz tube with a sharp point, in an induction furnace with argon protection Melt and mix the above ingredients uniformly in the process to obtain the master alloy, and finally use the spray casting device of the induction furnace to blow the melt of the master alloy into the copper mold to obtain the sample. The method can be used to obtain rod-shaped strontium-based bulk metallic glass with a diameter of 3 mm or a sheet-shaped strontium-based bulk metallic glass with a thickness of 2 mm.

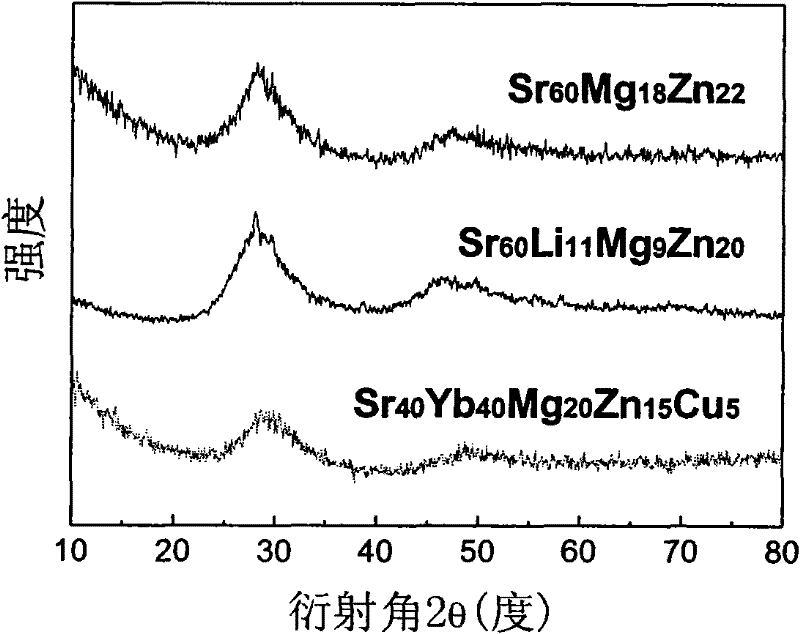

[0021] The Sr 60 Mg 18 Zn 22 X-ray diffraction pattern of strontium-based bulk metallic glass figure 1 As shown, there is a broad diffraction peak and no sharp crystallization peak, indicating that the sample is an amorphous ...

Embodiment 2

[0022] Example 2, Sr 60 Li 11 Mg 9 Zn 20 Preparation of strontium-based bulk metallic glasses

[0023] Strontium with a raw material purity of 99wt%, 99.9wt% zinc, and a magnesium-lithium alloy with a magnesium content of 75wt% are prepared according to the molar ratio of the four elements of strontium, lithium, magnesium, and zinc at 60:11:9:20, and then put into the belt In a pointed quartz tube, the above ingredients are melted and mixed evenly in an induction furnace with argon protection to obtain a master alloy, and finally the injection casting device of the induction furnace is used for spray casting. During the preparation of this sample, the copper mold was cooled with liquid nitrogen to obtain a larger size sample. The method can be used to obtain rod-shaped strontium-based bulk metallic glass with a diameter of 3 mm or a sheet-shaped strontium-based bulk metallic glass with a thickness of 2 mm.

[0024] The Sr 60 Li 11 Mg 9 Zn 20 X-ray diffraction pattern ...

Embodiment 3

[0025] Example 3, Sr 40 Yb 20 Mg 20 Zn 15 Cu 5 Preparation of strontium-based bulk metallic glasses.

[0026] Strontium and ytterbium with a raw material purity of 99wt%, and 99.9wt% magnesium, zinc and copper are prepared according to the molar weight of the elements at 40:20:20:15:5, and according to the preparation scheme in Example 1, you can get Rod-shaped with a diameter of 3mm or flake-shaped strontium-based bulk metallic glass with a thickness of 2mm.

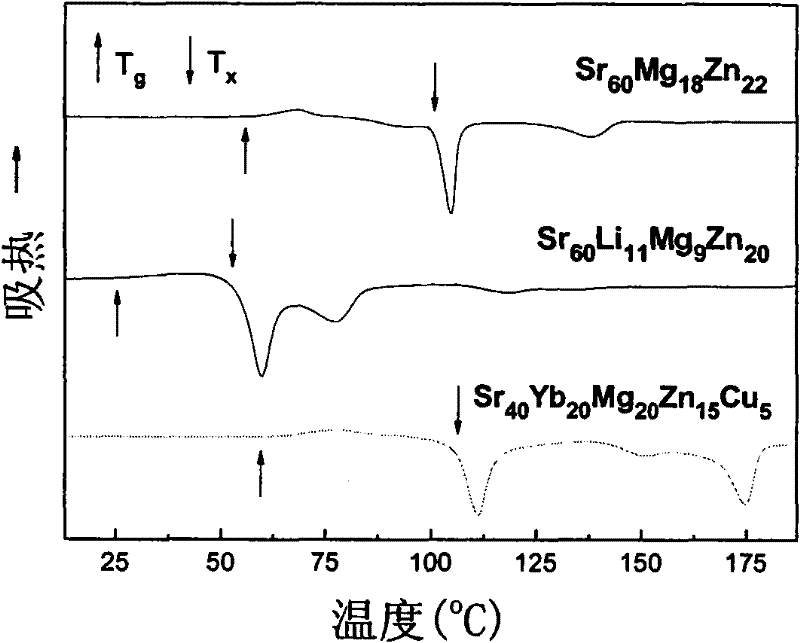

[0027] The Sr 40 Yb 20 Mg 20 Zn 15 Cu 5 X-ray diffraction pattern of strontium-based bulk metallic glass figure 1 As shown, there is a broad diffraction peak and no sharp crystallization peak, indicating that the sample is an amorphous alloy. Its DSC thermal analysis results are as follows figure 2 As shown, it can be seen that it has a lower glass transition temperature (63°C) and a wider supercooled liquid phase region (42°C), and the alloy has better oxidation and corrosion resistance than other alloys. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com