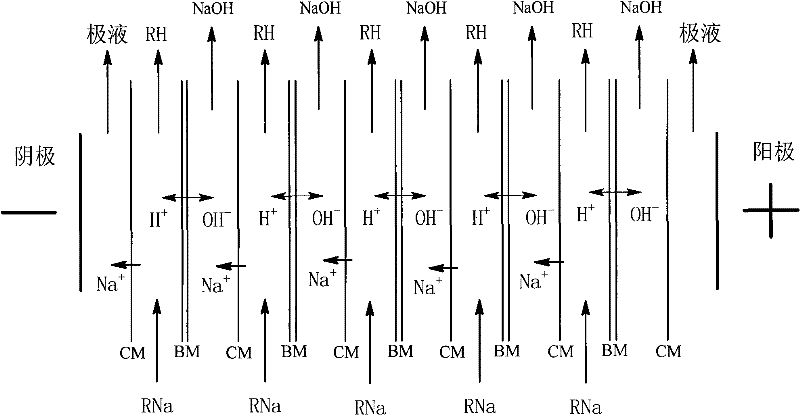

Bipolar membrane device for producing gluconic acid

A gluconic acid and bipolar membrane technology, applied in the field of mechanical devices, can solve the problems of low operating current density, low operating efficiency, and high gluconic acid loss, and achieve the effects of uniform current distribution, reduced voltage loss, and reduced investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

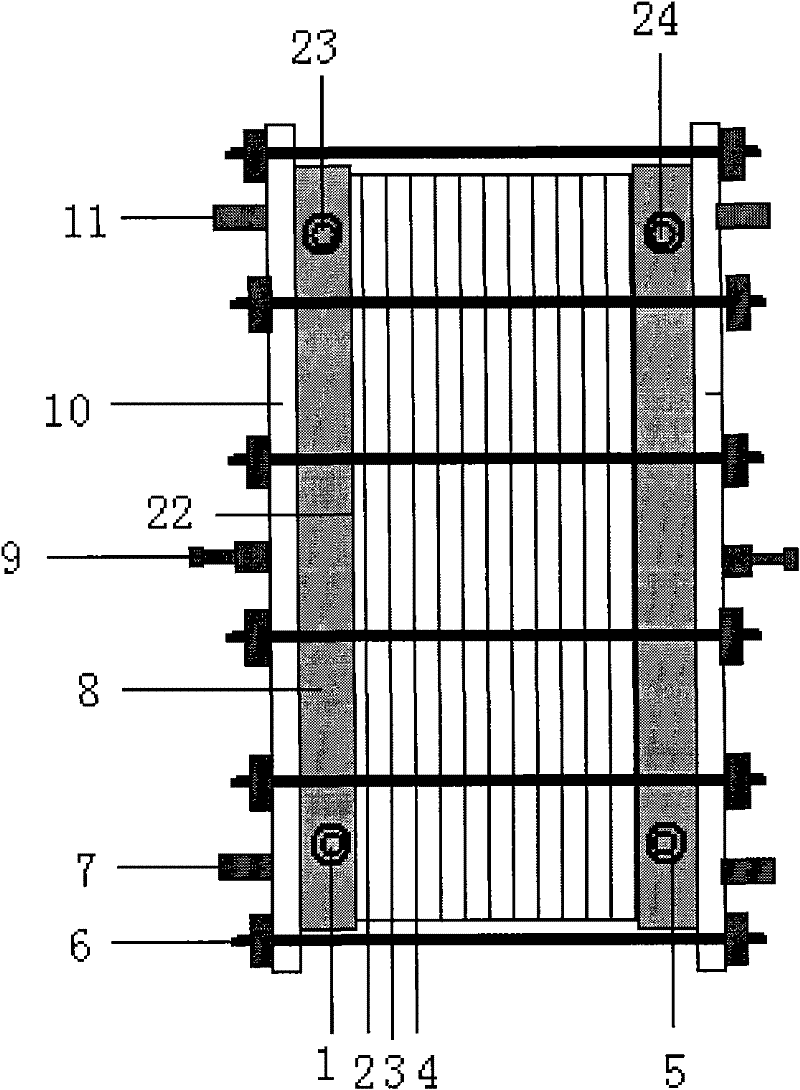

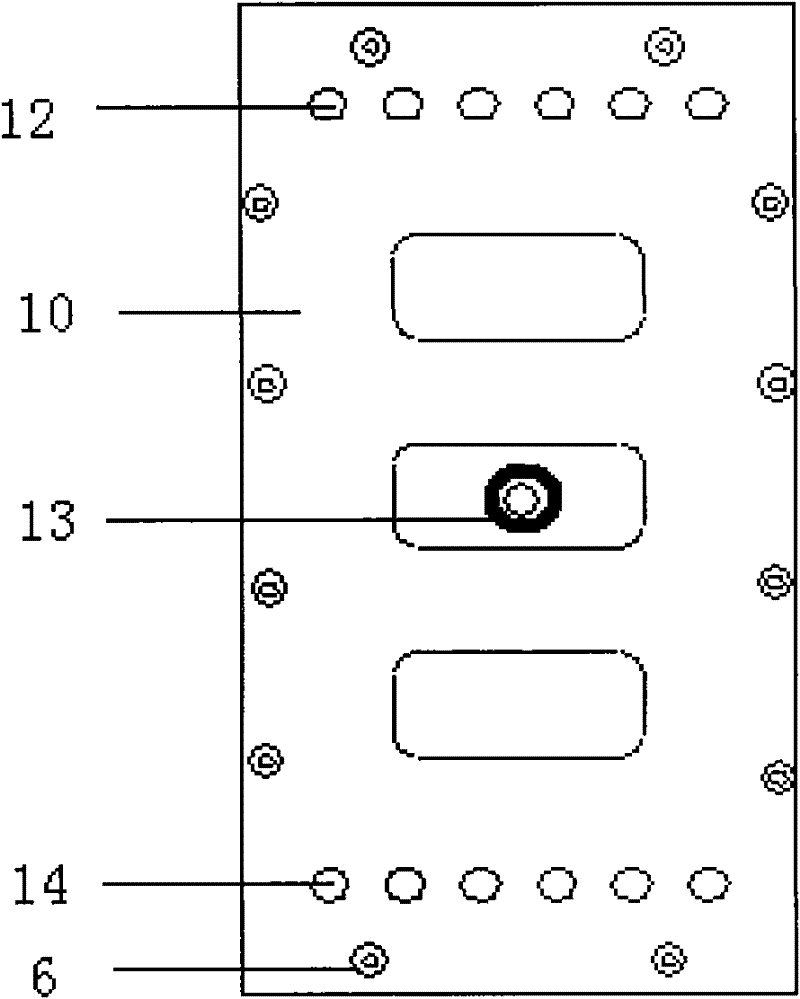

[0037] according to figure 2 , image 3 , Figure 4 , Figure 5 As shown in the structure, a bipolar membrane device is installed, including a clamping steel plate 10, an anode liquid channel plate 8, an electrode 22, an elastic separator 3, a homogeneous anodic membrane 2, a bipolar membrane 4, a fastening bolt 6, Feed liquid inlet 7, anode liquid flow channel plate 8, anode terminal 9, cathode terminal 13, elliptical liquid guide hole 17, net core separator 18, cathode terminal 13 is connected to cathode, anode terminal 9 is connected to anode ; A membrane stack space is formed between the cathode and the anode; the membrane group is placed in the membrane stack space, and the membrane group is placed as follows: homogeneous positive membrane 2, elastic separator 3, bipolar membrane 4, elastic separator 3, homogeneous The positive and negative membranes 2 are arranged in sequence; a net center spacer 18 is placed between the diaphragms; a semi-elliptical liquid guide hol...

Embodiment 2

[0041] Adopt the device in embodiment 1, wherein elastic coating 19 is polyurethane rubber type, adopts the film of 400*800 specification, altogether 150 groups, effective film area is 37.5 square, and electrode 22 is electroplated 1 micron thick on the 2 millimeter thick titanium alloy substrate The platinum layer adopts domestic bipolar membrane, the positive membrane adopts CSO membrane, the thickness of the separator is 0.7mm, and 3 groups of liquid guide holes are arranged side by side. Each liquid guide hole has 8 flow channels with a flow channel width of 0.2mm. The concentration of sodium feed solution is 30%, the concentration of sodium hydroxide chamber is 10%, and the current density is 600A / cm 2 Constant flow operation, membrane surface flow velocity 8cm / s, feed pressure 0.06MPa, pipe flow velocity 1.0m / s, liquid guide hole flow velocity 0.5m / s, membrane stack locking torque 45 N.m, continuous operation for 50 Hour. In the process of operation, except that the tem...

Embodiment 3

[0043] Using the device in Example 1, the elastic separator 3 is coated with an elastic coating 19 with a mass ratio of 2:1:0.5 of silicone rubber type: liquid polysulfide rubber type: flexible PVC elastic blend. 550*1100 membranes are used, 50 groups in total, the effective membrane area is 25 square meters, the electrode 22 is a 2 mm thick platinum plate, the domestic bipolar membrane is used, the positive membrane is HSF membrane, the thickness of the separator is 0.7mm, and the liquid guide holes are arranged side by side. 4 groups, the flow channel of each guide hole is 8 channels, the flow channel width is 0.2mm, the concentration of sodium gluconate feed solution is 30%, the concentration of sodium hydroxide chamber is 10%, and the current density is 600A / cm 2 Constant flow operation, membrane surface velocity 9cm / s, feed pressure 0.07MPa, pipe flow velocity 1.0m / s, liquid guide hole velocity 0.5m / s, membrane stack locking torque 35 N.m, continuous operation for 50 Hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com