Method of preparing calcium sulfate whisker by using agglomerate fume desulfurized by-products

A technology of calcium sulfate whiskers and desulfurization by-products, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., to achieve low production costs, alleviate environmental pollution, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

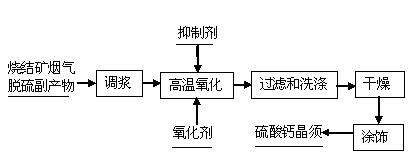

Image

Examples

Embodiment 1

[0025] The process steps of the method for preparing calcium sulfate whiskers by utilizing sinter flue gas desulfurization by-products are as follows:

[0026] (1) Blending

[0027] Mix the by-products of flue gas desulfurization of sintering ore with water at a solid-to-liquid volume ratio of 1:12 to obtain a suspension.

[0028] (2) High temperature oxidation

[0029] Add oxidants and inhibitors to the suspension prepared in step (1), adjust the pH value to 6, stir, the stirring speed is controlled at 95 rpm, and under the conditions of temperature 200 ° C and pressure 5 MPa, keep warm for 270 min, carry out the oxidation reaction.

[0030] The oxidant used is oxygen; the inhibitor used is sodium phosphate; in terms of mass percentage, the amount of oxidant added is 5% of the mass of the suspension, and the amount of the inhibitor is 5% of the mass of the suspension.

[0031] (3) Filtration and washing

[0032] Vacuum suction filtration is performed on the material after...

Embodiment 2

[0040] The process steps of the method for preparing calcium sulfate whiskers by utilizing sinter flue gas desulfurization by-products are as follows:

[0041] (1) Blending

[0042] Mix the by-products of flue gas desulfurization of sintered ore with water at a solid-to-liquid volume ratio of 1:20 to obtain a suspension.

[0043] (2) High temperature oxidation

[0044] Add oxidants and inhibitors to the suspension prepared in step (1), adjust the pH value to 10, stir, and control the stirring speed to 150 rpm, and keep it warm for 40 minutes at a temperature of 300 °C and a pressure of 10 MPa. carry out the oxidation reaction.

[0045]The oxidant that adopts is sodium hypochlorite; The inhibitor that adopts is nitric acid, and the mass concentration of nitric acid is 1.5%; By mass percentage, the addition of oxidant is 10% of suspension quality, and the consumption of inhibitor is 10% of suspension quality.

[0046] (3) Filtration and washing

[0047] The material after hi...

Embodiment 3

[0055] The process steps of the method for preparing calcium sulfate whiskers by utilizing sinter flue gas desulfurization by-products are as follows:

[0056] (1) Blending

[0057] Mix the by-products of sinter flue gas desulfurization with water at a solid-to-liquid volume ratio of 1:4 to obtain a suspension.

[0058] (2) High temperature oxidation

[0059] Add oxidants and inhibitors to the suspension prepared in step (1), adjust the pH value to 2, stir, and control the stirring speed to 40 rpm, and keep it warm for 500min at a temperature of 110°C and a pressure of 0.2MPa , for an oxidation reaction.

[0060] The oxidant used is potassium hypochlorite; the inhibitor used is magnesium phosphate; in terms of mass percentage, the amount of oxidant added is 0.5% of the mass of the suspension, and the amount of the inhibitor is 0.5% of the mass of the suspension.

[0061] (3) Filtration and washing

[0062] The material after high temperature oxidation is subjected to plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Loose density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com