Regeneration method of activated carbon in organosilicon wastewater treatment

A wastewater treatment and organic silicon technology, applied in the direction of adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the secondary pollution of the environment, activated carbon cannot be recycled, and increase the cost of wastewater treatment and other problems, to achieve the unique ability, reduce the cost of sewage treatment, and improve the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

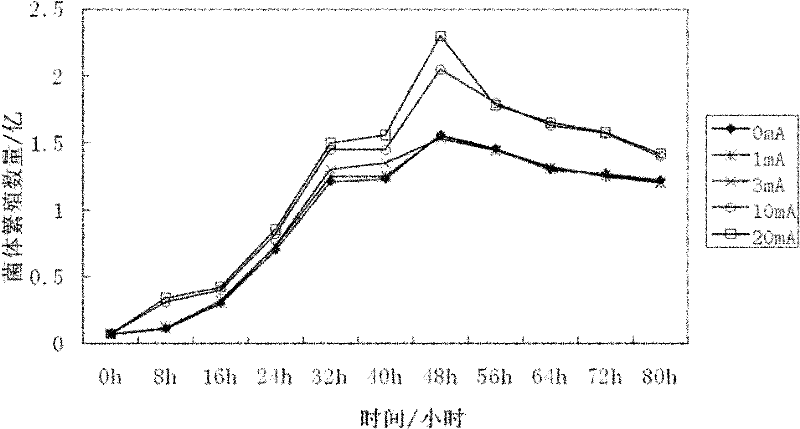

[0027] Example 1: Effect of electric field on microbial growth and metabolism in organosilicon wastewater

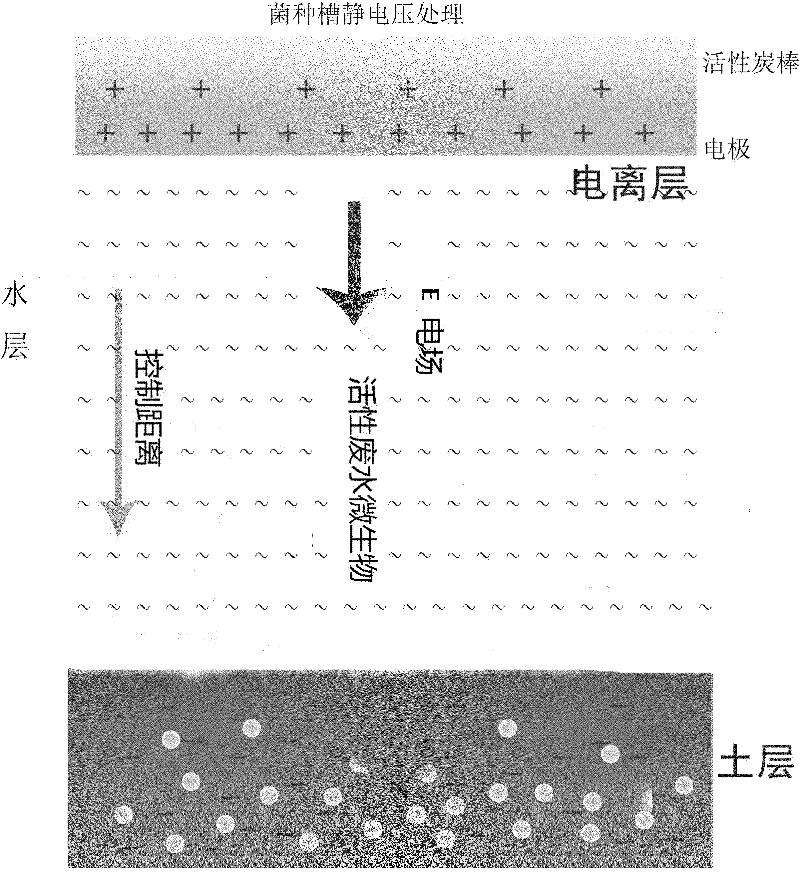

[0028] Static pressure treatment of strain tank: used to cultivate microorganisms and create a living environment for microorganisms. The ionosphere is in the form of an electrode column probe, surrounded by a ring of concrete around the electrode, the electrode column is connected to the positive pole of the DC power supply, and the concrete layer is connected to the negative pole of the DC power supply (see attached figure 1 ), the distance from the electrode to the concrete side wall is 0.5m, and the built-in nutrient solution is prepared according to the following composition: glucose: 4g; urea: 0.3g; ferric chloride: 0.1g; dipotassium hydrogen phosphate: 0.07g; potassium dihydrogen phosphate 0.2g; MS trace element mother solution 1mL (KI 0.083g, Na 2 MoO 4 2H 2 O 0.025g, H 3 BO 3 0.62g, CuSO 4 ·5H 2 O0.0025g, MnSO 4 ·H 2 O 1.69g, CoCl 2 6H2O 0.0025g, ZnSO ...

Embodiment 2

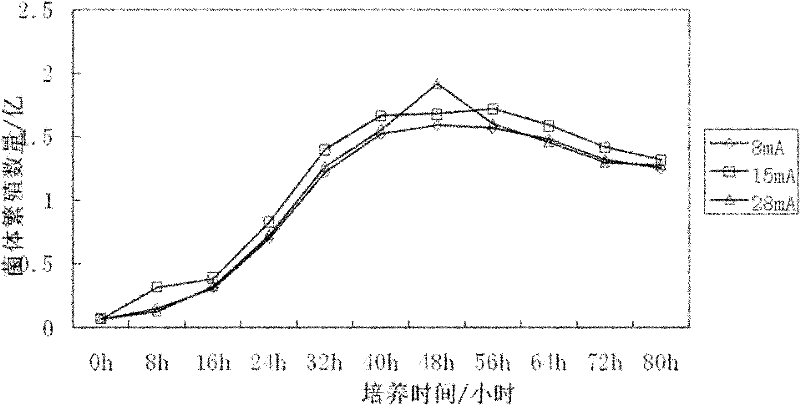

[0032]The strain tank is the same as in Example 1, the distance from the electrode to the concrete side wall is 0.5m, and the built-in nutrient solution is prepared according to the following composition: glucose: 4g; urea: 0.3g; ferric chloride: 0.1g; dipotassium hydrogen phosphate: 0.07 g; potassium dihydrogen phosphate 0.2g; MS trace element mother solution 1mL; tap water 1000ml, pH 7.5.

[0033] Take the activated sludge from the biochemical treatment of organosilicon wastewater, add it into the nutrient solution (addition amount 20g / L), apply an electric field of 20mA in the nutrient solution, and incubate at 28-30°C for 18h;

[0034] Silicone wastewater treatment:

[0035] Organosilicon wastewater with a COD value of 36000mg / L first enters the biochemical tank, the effluent passes through the coagulation tank, is precipitated by milk of lime, and then enters the sedimentation tank. The residual wastewater is adsorbed with activated carbon, and the wastewater after adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com