Olefinic polymerization non-metallocene metal catalyst system and preparation and application thereof

A non-metallocene and olefin polymerization technology, applied in the field of copolymerization non-metallocene catalyst system, can solve the problems such as catalyst research report, large amount of MAO, etc., and achieves less amount of MAO, high catalyst activity, and polymer molecular weight. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

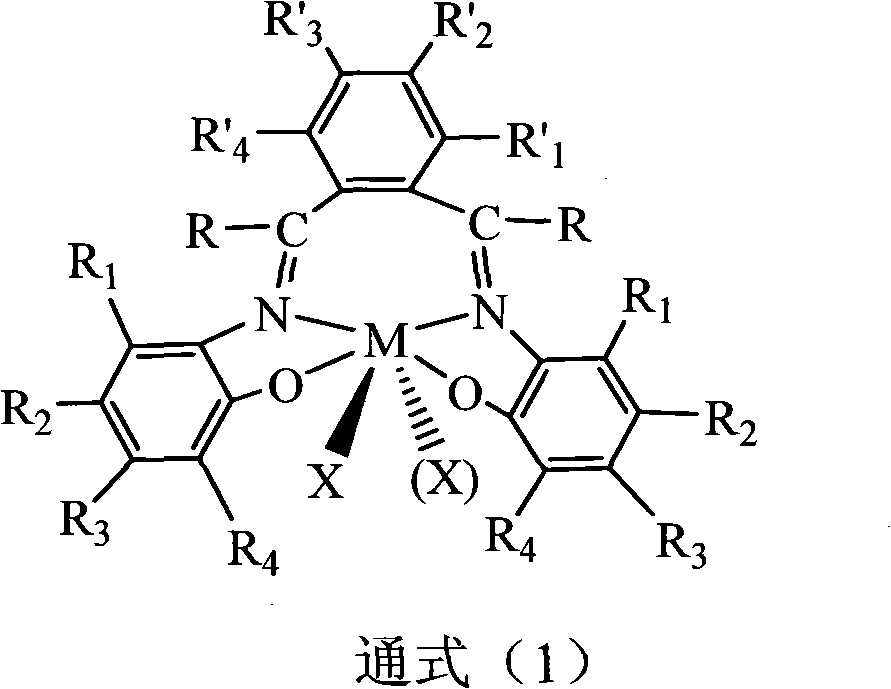

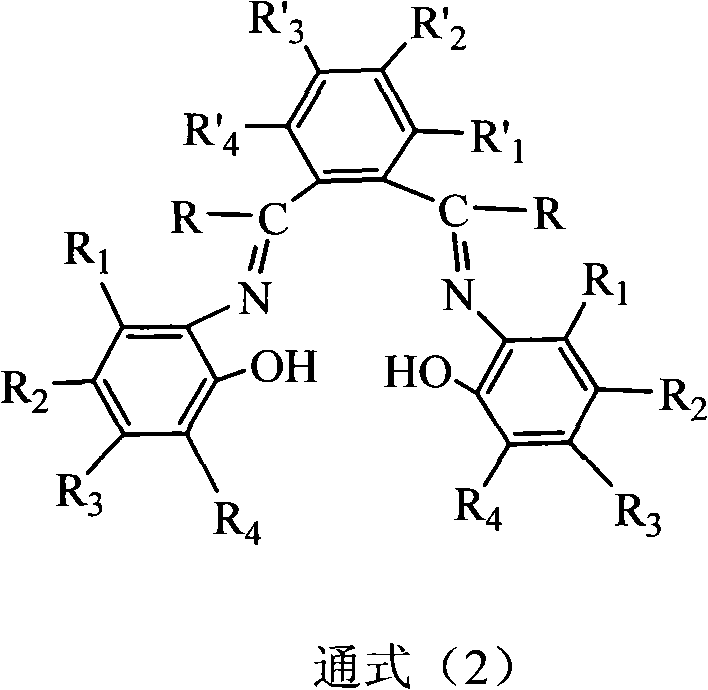

[0044] 1) Preparation of the ligand: under the protection of an inert gas, add 0.68g (5mmol) o-phthalaldehyde and 1.26g (10mmol) 2-amino-4-methylphenol to 50mL of absolute ethanol in sequence, and reflux at 80°C Reaction 8h. Cool to room temperature, obtain solid precipitation, wash three times with anhydrous ether, then recrystallize with the mixed solution (3:1) of toluene and chloroform, obtain 1.57g ligand L1 (see general formula (2)), productive rate 91%.

[0045] 2) Preparation of non-metallocene main catalyst for olefin polymerization: anhydrous and oxygen-free and under the protection of high-purity nitrogen, 0.69g (2mmol) ligand L1 was dissolved in 80mL toluene / tetrahydrofuran (1:1) mixed solvent, at 0 0.22mL (2mmol) TiCl was added dropwise at ℃ (ice-water bath) 4 After the dropwise addition, the temperature was slowly raised to 40° C. for 6 h, the solvent was removed in vacuo, the precipitate was washed 3 times with n-hexane, filtered, and vacuum-dried to obtain th...

Embodiment 2

[0050] 1) Preparation of ligands: under the protection of inert gas, add 1.02g (5mmol) 4-trifluoromethyl-phthalaldehyde, 1.26g (10mmol) 2-amino-4-methyl Phenol, reflux reaction at 90°C for 8h. Cool to room temperature, obtain solid precipitation, wash three times with anhydrous ether, then recrystallize with the mixed solution (3:1) of toluene and chloroform, obtain 1.82g ligand L2 (see general formula (2)), productive rate 88%.

[0051] 2) Preparation of non-metallocene main catalyst for olefin polymerization: anhydrous and oxygen-free and under the protection of high-purity nitrogen, 0.83g (2mmol) ligand L2 was dissolved in 50mL toluene / tetrahydrofuran (1:1) mixed solvent, in- Add 0.22mL (2mmol) TiCl dropwise at 10°C (ice-water bath) 4 , after the dropwise addition was completed, the temperature was slowly raised to 30° C. for 8 h, the solvent was removed in vacuo, the precipitate was washed 3 times with n-hexane, filtered, and vacuum-dried to obtain the main catalyst comp...

Embodiment 3

[0054] 1) Preparation of the ligand: under the protection of an inert gas, add 0.96g (5mmol) 4-tert-butylphthalaldehyde and 1.26g (10mmol) 2-amino-4-methylphenol successively to 50mL of absolute ethanol. 80 ° C reflux reaction for 12h. Cool to room temperature, obtain solid precipitation, wash three times with anhydrous ether, then recrystallize with the mixed solution (3:1) of toluene and chloroform, obtain 1.74g ligand L3 (see general formula (2)), productive rate 87%.

[0055] 2) Preparation of non-metallocene main catalyst for olefin polymerization: anhydrous and oxygen-free and under the protection of high-purity nitrogen, 0.80g (2mmol) of ligand L3 was dissolved in 50mL of toluene / tetrahydrofuran (1:1) mixed solvent, in 10 Add 0.22mL (2mmol) TiCl dropwise at ℃ 4 , after the dropwise addition was completed, the temperature was slowly raised to 60° C. for 6 h, the solvent was removed in vacuo, the precipitate was washed 3 times with n-hexane, filtered, and vacuum-dried t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com