Near-infrared absorption film material with night vision compatible characteristic and preparation method thereof

A near-infrared and near-infrared technology, applied in radiation-absorbing coatings, chemical instruments and methods, epoxy resin coatings, etc., can solve the problems of unseen coating materials and film materials, and achieve light weight, low production cost, The effect of good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

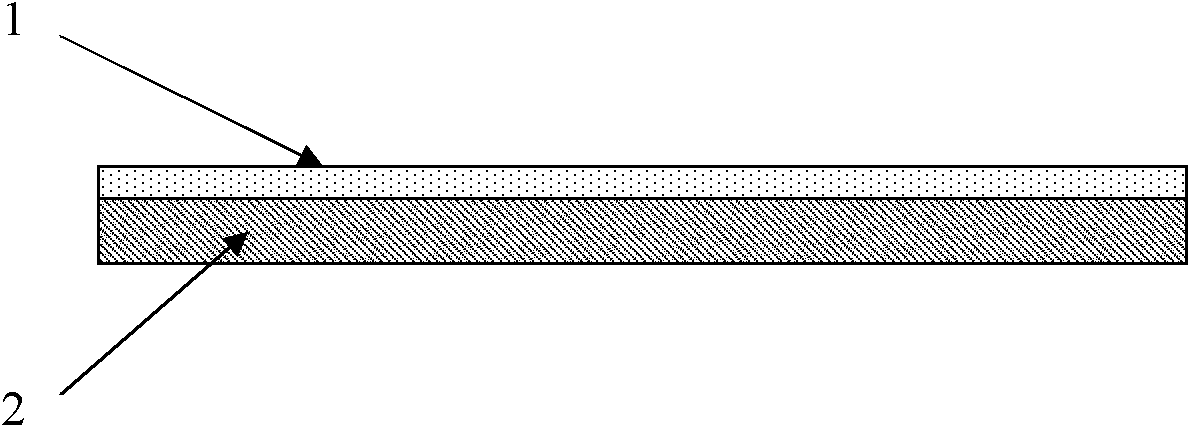

[0033] (1) Use ethylene terephthalate (PET) film as the transparent substrate with a thickness of 0.1 mm.

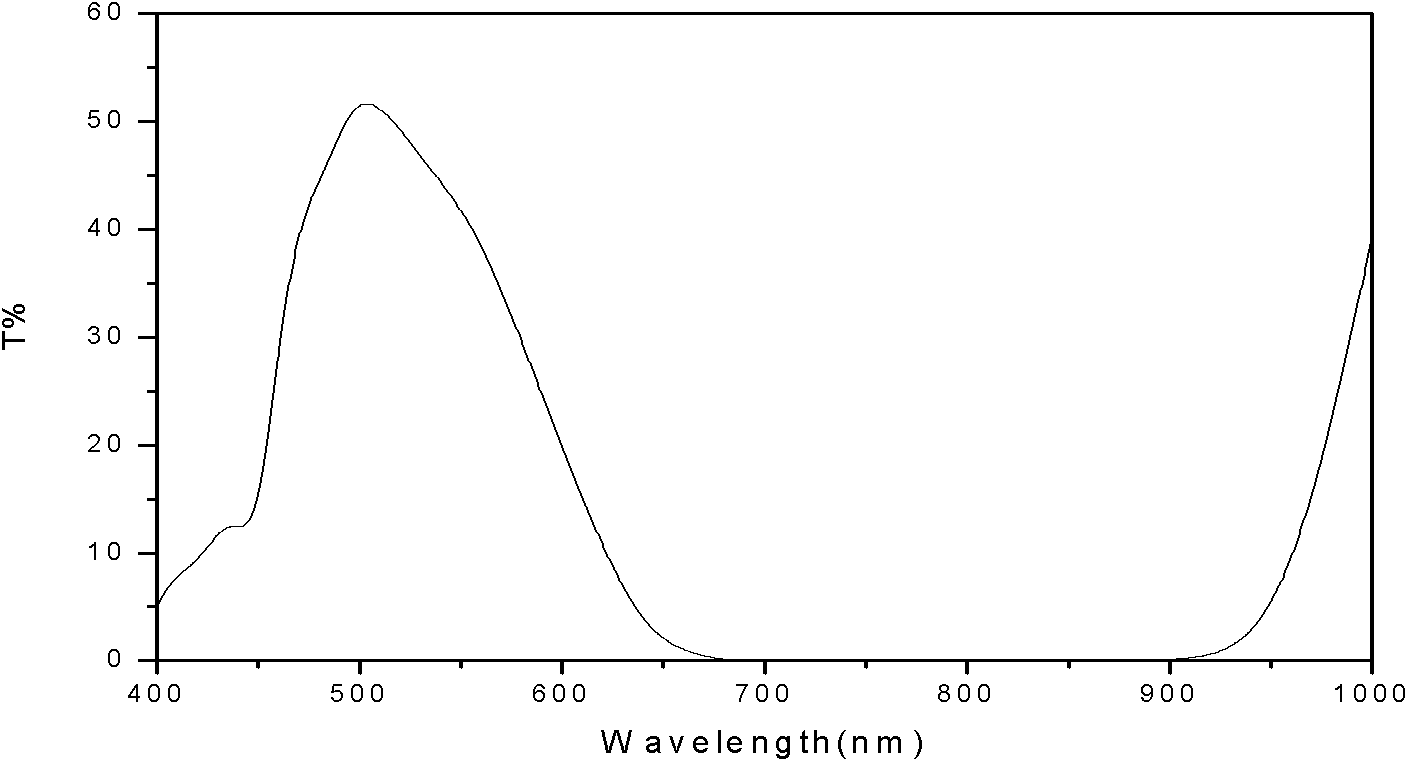

[0034] (2) Coating material components of the near-infrared absorbing layer: acrylic resin (Kunshan East Asia resin, DY8236), 100 parts by mass; acrylic resin curing agent (Bayer, Desmodur-N75), 10 parts by mass; thiodiene type Nickel (molecular formula: C 28 h 20 NeS 4 ; Absorption peak λ max =855nm), 0.25 parts by mass; polymethine cyanine dyes (molecular formula: C 32 h 36 ClN 2 .I; absorption peak λ max =775nm), 0.15 parts by mass; dichloromethane, 50 parts by mass.

[0035] (3) Add the two near-infrared absorbers described in (2) into dichloromethane, and stir for 15 minutes by magnetic force to obtain a uniform solution. Then add the matrix resin and resin curing agent into the solution, and continue stirring with a magnetic stirrer for 30 minutes, and the near-infrared absorption coating material is obtained after the system is uniformly dispersed.

[003...

Embodiment 2

[0043] (1) A PET film is selected as the transparent substrate with a thickness of 0.05mm.

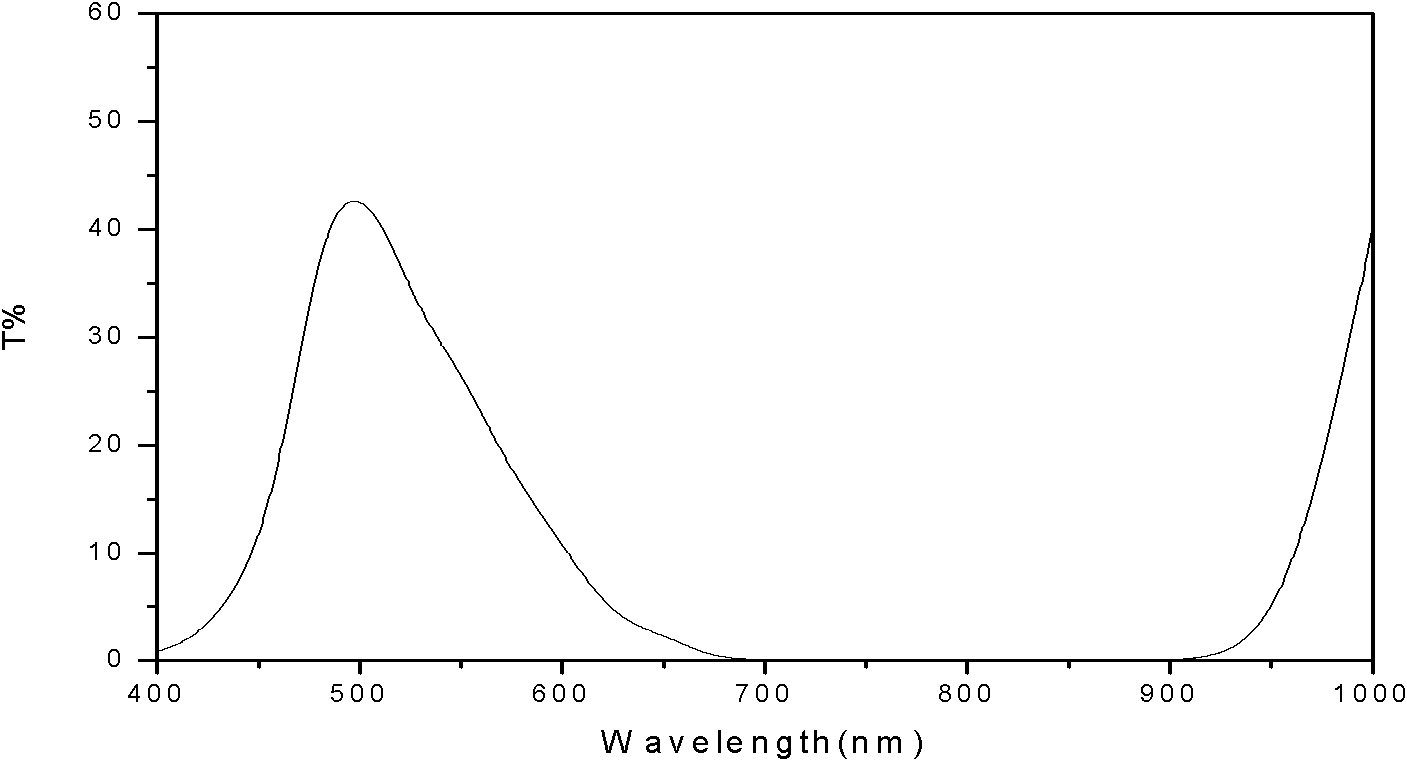

[0044] (2) Coating material components of the near-infrared absorbing layer: fluorocarbon resin (Changshu Zhonghao resin, JF-4XB), 100 parts by mass; fluorocarbon resin curing agent (Japan Polyurethane Company, Coronate2030), 10 parts by mass; sulfur Substituted diene nickel (molecular formula: C 28 h 20 NeS 4 ; Absorption peak λ max =855nm), 0.1 parts by mass; anthraquinone dyes (molecular formula: C 42 h 36 o 2 N 4 ; Absorption peak λ max =755nm), 0.05 parts by mass; chloroform, 30 parts by mass.

[0045] (3) Add the two near-infrared absorbers described in (2) into chloroform, and stir for 10 minutes by magnetic force to obtain a uniform solution. Then add the matrix resin and resin curing agent into the solution, and continue stirring with a magnetic stirrer for 15 minutes. After the system is uniformly dispersed, a near-infrared-absorbing coating material is obtained.

...

Embodiment 3

[0053] (1) Polycarbonate (PC) film is selected as the transparent substrate with a thickness of 0.1 mm.

[0054] (2) The coating material component of the near-infrared absorbing layer: epoxy resin (Wuxi Blue Star Resin, WSR6101), 100 parts by mass; epoxy resin curing agent (Basf, Germany, Polyetheramine D 230), 20 parts by mass; free radical Type dye (molecular formula: C 62 h 92 N 6 .PF 6 ; Absorption peak λ max =950nm), 0.25 parts by mass; polymethine cyanine dyes (molecular formula: C 32 h 36 ClN 2 .I; absorption peak λ max =775nm), 0.15 parts by mass; acetone, 50 parts by mass.

[0055] (3) Add the two near-infrared absorbers described in (2) into acetone, and stir for 15 minutes by magnetic force to obtain a uniform solution. Then add the matrix resin and resin curing agent into the solution, and continue stirring with a magnetic stirrer for 30 minutes, and the near-infrared absorption coating material is obtained after the system is uniformly dispersed.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com