Preparation method of porous CuAlMn shape memory alloy

A technology of memory alloys and particles, which is applied in the field of preparation of porous CuAlMn shape memory alloys, can solve the problems of increasing process complexity and technical difficulty, and achieve the effects of improving efficiency and product quality, increasing degrees of freedom, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

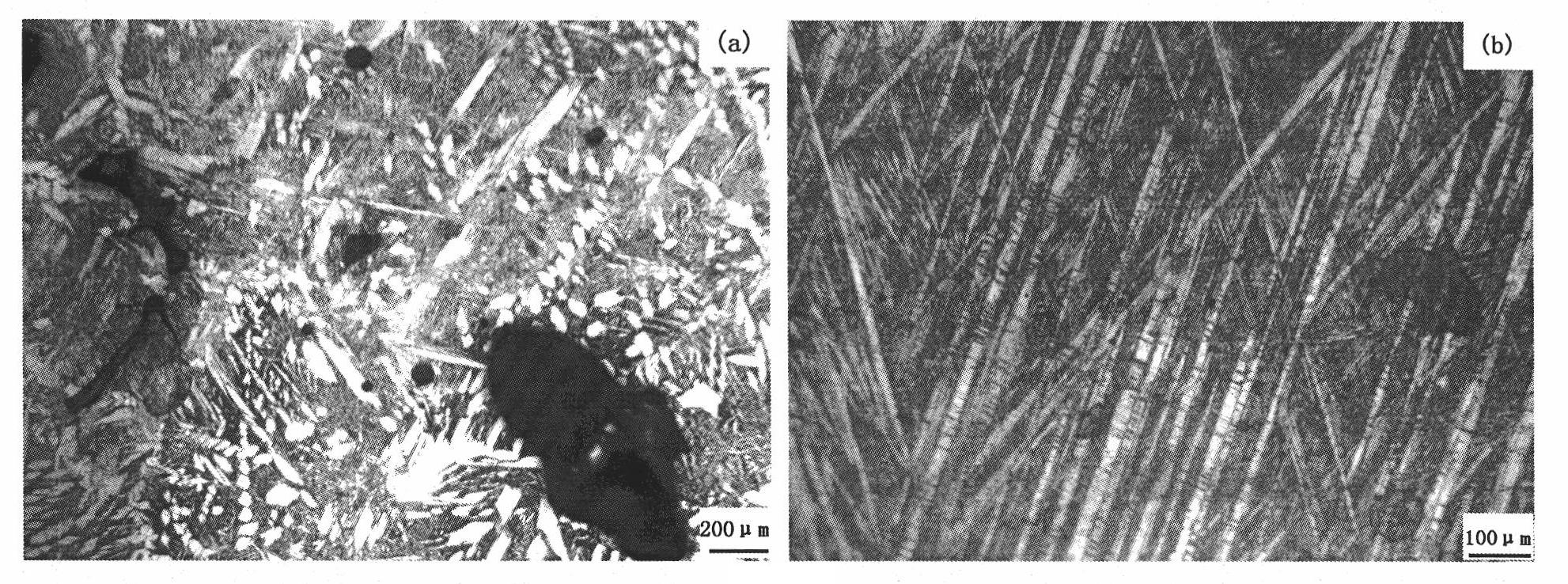

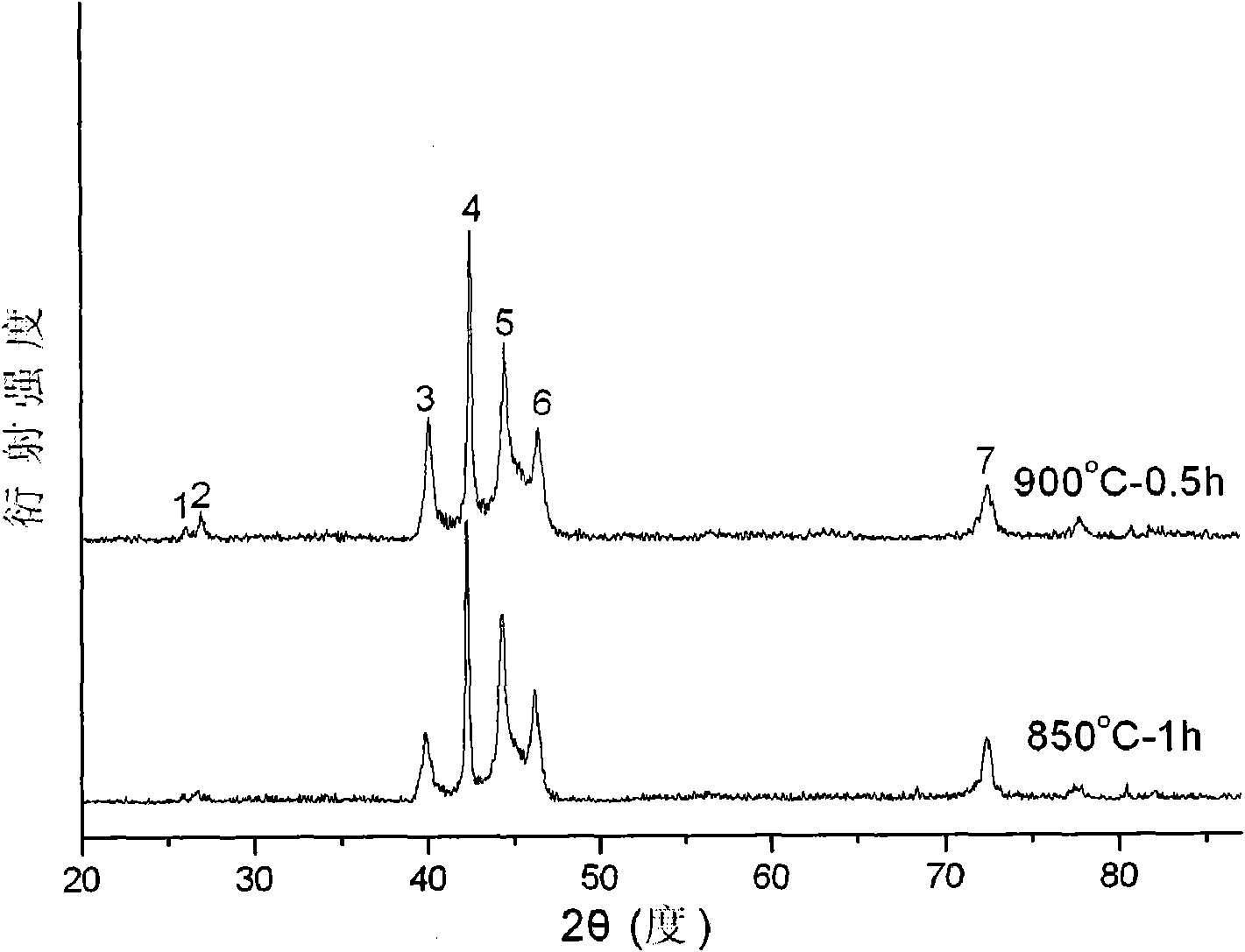

Embodiment 1

[0039] The first step, the preparation of CuAlMn shape memory alloy powder raw materials

[0040] Get the required amount of CuAlMn shape memory alloy powder made by atomization, add AlF that accounts for 0.08% of the total mass of the memory alloy powder 3 +CaF 2 Powder additive, AlF 3 with CaF 2 The mass ratio of the mixture was 4: 1, and it was ball milled on a planetary ball mill for 1.5 hours under argon protection, and the ball-to-material ratio was 10: 1 in the ball mill, and the rotating speed of the ball mill was 200 rpm;

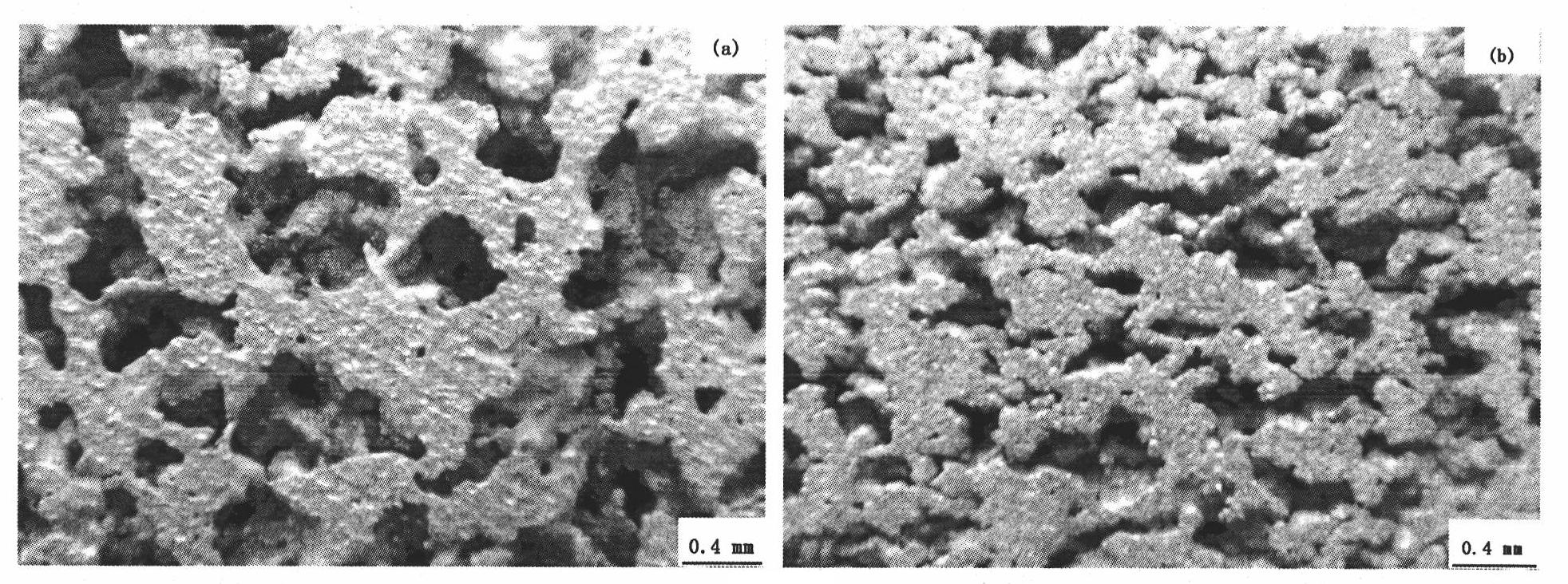

[0041] The second step, the preparation of decrystallization water NaCl particles

[0042] Carry out decrystallization water treatment on commercially available NaCl particles, then sieve NaCl particles with different particle sizes, and select decrystallization water NaCl particles with an average particle size of 0.2mm;

[0043] The third step is to prepare the green body

[0044] The decrystallized water NaCl particles with an average parti...

Embodiment 2

[0053] The first step, the preparation of CuAlMn shape memory alloy powder raw materials

[0054] Get the required amount of CuAlMn shape memory alloy powder made by atomization method, add AlF which accounts for 0.07% of the total mass of the memory alloy powder 3 +CaF 2 Powder additive, AlF 3 with CaF 2 The mass ratio of the mixture was 4: 1, and it was ball milled on a planetary ball mill for 1.5 hours under argon protection, and the ball-to-material ratio was 10: 1 in the ball mill, and the rotating speed of the ball mill was 200 rpm;

[0055] The second step, the preparation of decrystallization water NaCl particles

[0056] Carry out decrystallization water treatment on commercially available NaCl particles, then sieve NaCl particles with different particle sizes, and select decrystallization water NaCl particles with an average particle size of 0.4mm;

[0057] The third step is to prepare the green body

[0058] The decrystallized water NaCl particles with an avera...

Embodiment 3

[0071] The first step, the preparation of CuAlMn shape memory alloy powder raw materials

[0072] Get the required amount of CuAlMn shape memory alloy powder made by atomization method, add AlF which accounts for 0.06% of the total mass of the memory alloy powder 3 +CaF 2 Powder additive, AlF 3 with CaF 2 The mass ratio of the mixture was 4: 1, and it was ball milled on a planetary ball mill for 1.5 hours under argon protection, and the ball-to-material ratio was 10: 1 in the ball mill, and the rotating speed of the ball mill was 200 rpm;

[0073] The second step, the preparation of decrystallization water NaCl particles

[0074] Carry out decrystallization water treatment on commercially available NaCl particles, then sieve NaCl particles with different particle sizes, and select decrystallization water NaCl particles with an average particle size of 1 mm;

[0075] The third step is to prepare the green body

[0076] The decrystallization water NaCl particles with an avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com