Nifedipine controlled release micro-pill preparation and preparation method thereof

A technology of nifedipine and dipine pellets, used in the field of medicine, can solve problems such as damage to the ability to drive and operate machines, gingival hyperplasia, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of pill core:

[0024] Prescription: Nifedipine 800g

[0025] Sucrose Blank Ball Core 300g

[0026] Povidone 30g

[0027] Preparation process: dissolving the prescribed amount of povidone in ethanol solution to prepare a 3% povidone ethanol solution as an adhesive. Micronize nifedipine, weigh the prescription amount and add it to the hopper, put the blank pellet core in the coating granulator, spray the adhesive and start adding the drug until all the nifedipine is added, take it out and put it on the tray , Dry at 40±5°C.

[0028] (2) Controlled-release coating: Take 300g of drug-containing pill cores, and use the following coating prescription for coating:

[0029] Coating Solution Prescription:

[0030] Eudragit NE30D 100g

[0032] water 170g

[0033] Preparation of coating solution: take the Eudragit NE30D aqueous dispersion, talcum powder and water in the prescribed amount, mix and stir evenly, and use it as a coatin...

Embodiment 2

[0039] (1) Preparation of pill core:

[0040] Prescription: Nifedipine 800g

[0041] Starch Blank Ball Core 300g

[0042] Hypromellose 30g

[0043] Preparation process: dissolving prescription amount of hydroxypropyl cellulose in ethanol solution to prepare 3% hydroxypropyl cellulose ethanol solution as binder. Micronize nifedipine, weigh the prescription amount and add it to the hopper, put the blank pellet core in the coating granulator, spray the adhesive and start adding the drug until all the nifedipine is added, take it out and put it on the tray , Dry at 40±5°C.

[0044] (2) Controlled release coating: 300g containing pill core, coated with the following coating prescription:

[0045] Coating Solution Prescription:

[0046] Eudragit RL100 100g

[0048] water 170g

[0049] Preparation of coating solution: Take the Eudragit RL100 aqueous dispersion, talcum powder and water in the prescribed amount, mix and stir evenly, and use it as a coat...

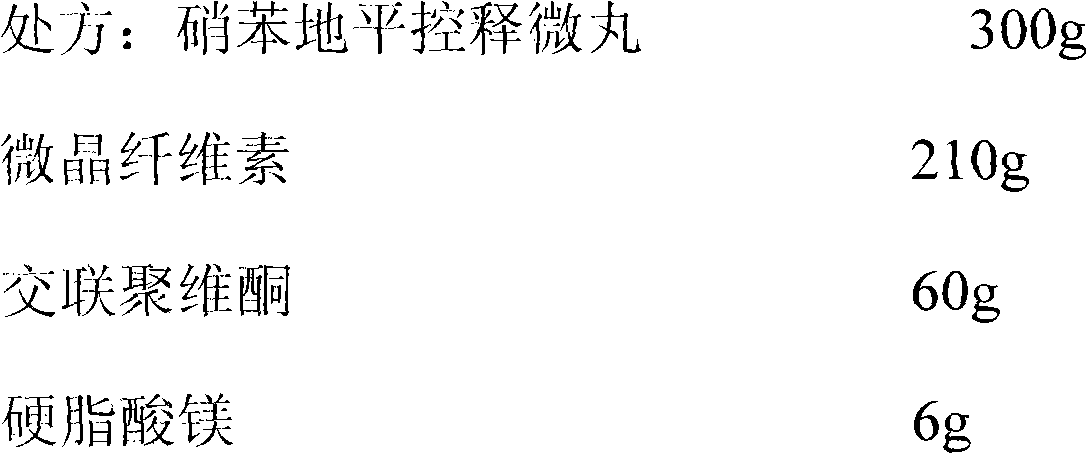

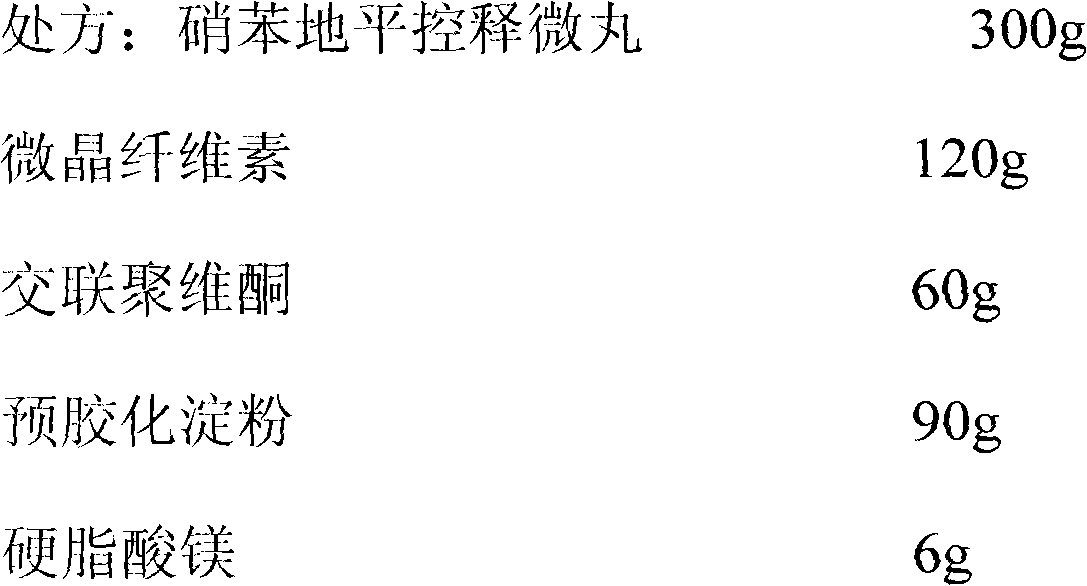

Embodiment 3

[0057] (1) Preparation of pill core:

[0058] Prescription: Nifedipine Control 650g

[0059] Microcrystalline Cellulose Blank Ball Core 200g

[0060] Methylcellulose 30g

[0061] Preparation process: dissolving the prescribed amount of methyl cellulose in ethanol solution to prepare 3% methyl cellulose ethanol solution as a binder. Micronize nifedipine, weigh the prescription amount and add it to the hopper, put the blank pellet core in the coating granulator, spray the adhesive and start adding the drug until all the nifedipine is added, take it out and put it on the tray , Dry at 40±5°C.

[0062] (2) Sustained-release coating: remove 300g of the core of the drug-containing pill, and use the following coating prescription for coating:

[0063] Coating Solution Prescription:

[0064] Ethylcellulose 69g

[0065] Talc powder 20g

[0066] water 150g

[0067] Preparation of coating solution: take ethyl cellulose, talcum powder and water in the prescribed amount, mix and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com