Catalyst for purifying exhaust gas of natural gas engine and preparation method thereof

A technology of exhaust purification and catalyst, which is applied in the field of natural gas engine exhaust purification catalyst and its preparation, can solve the problems of poor catalytic effect and high light-off temperature, and achieve the effects of improving stability, high catalytic activity and reducing the amount of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

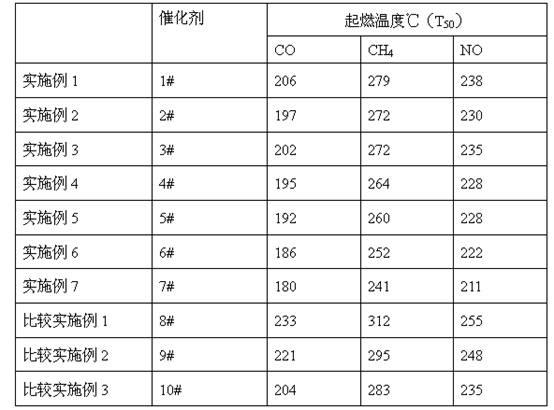

Examples

Embodiment 1

[0032] A cordierite honeycomb ceramic carrier with a diameter of 76.2mm and a height of 50mm (volume 0.228L) and a pore density of 400cpsi was placed in a 110°C drying oven to dry, and then purged. Weigh 300g of deionized water, add 124g of γ-Al to the aqueous solution 2 o 3 , 30g lanthanum yttrium modified cerium zirconium solid solution, 10g lanthanum oxide, 10g praseodymium oxide, 14g manganese oxide, 6g barium oxide, 6g aluminum glue, stirred at room temperature, while adjusting the pH value to 4, to prepare coating slurry. Then it was uploaded on an automatic coating machine, the excess slurry was purged with air, dried at 110°C for 8 hours, and calcined at 650°C for 4 hours.

[0033] Weigh 0.46gPd(NO 3 ) 2 (measured as Pd), 0.024gPt(NO 3 ) 2(Measured by Pt), add 80 g of deionized water to make active component solution. The active component is impregnated on the coated carrier by equal-volume impregnation method, dried at 110°C for 8 hours, and calcined at 650°C fo...

Embodiment 2

[0035] The preparation method is the same as in Example 1, except that 14g of manganese oxide is replaced by MnO with a manganese / cobalt molar ratio of 4:1 x -CoO x manganese-cobalt transition metal composite oxide to obtain catalyst 2# of the present invention.

Embodiment 3

[0037] The preparation method is the same as in Example 1, except that 14g of manganese oxide is replaced by FeO with an iron / cobalt molar ratio of 4:1 x -CoO x Iron-cobalt transition metal composite oxide to obtain catalyst 3# of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com