Method for preparing slow-release polycarboxylic acid water reducing agent by using molecular assembly technology

A slow-release polycarboxylic acid and assembly technology technology, which is applied in the field of molecular assembly technology for the preparation of slow-release polycarboxylate water-reducing agents, can solve the problems of unseen industrialized production and application, poor selectivity and repeatability, and the like. Good repeatability, easy operation and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

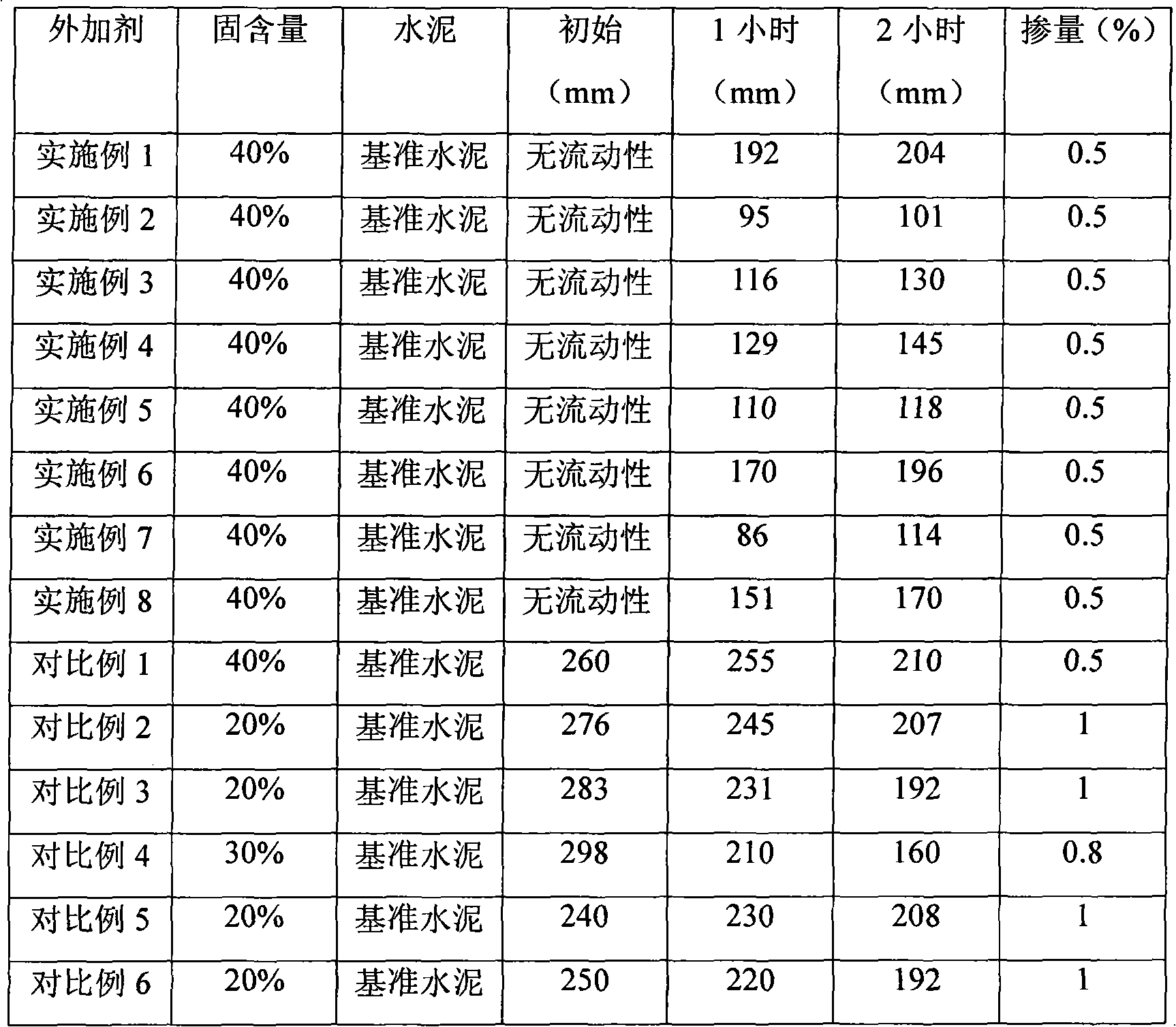

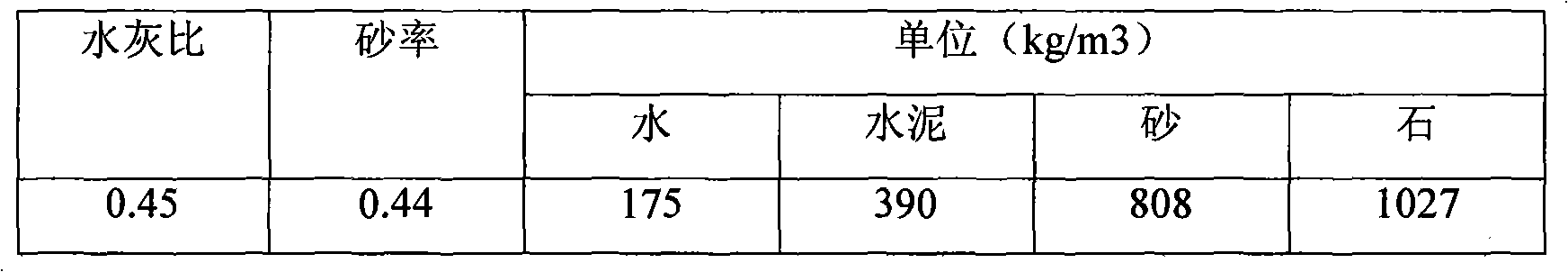

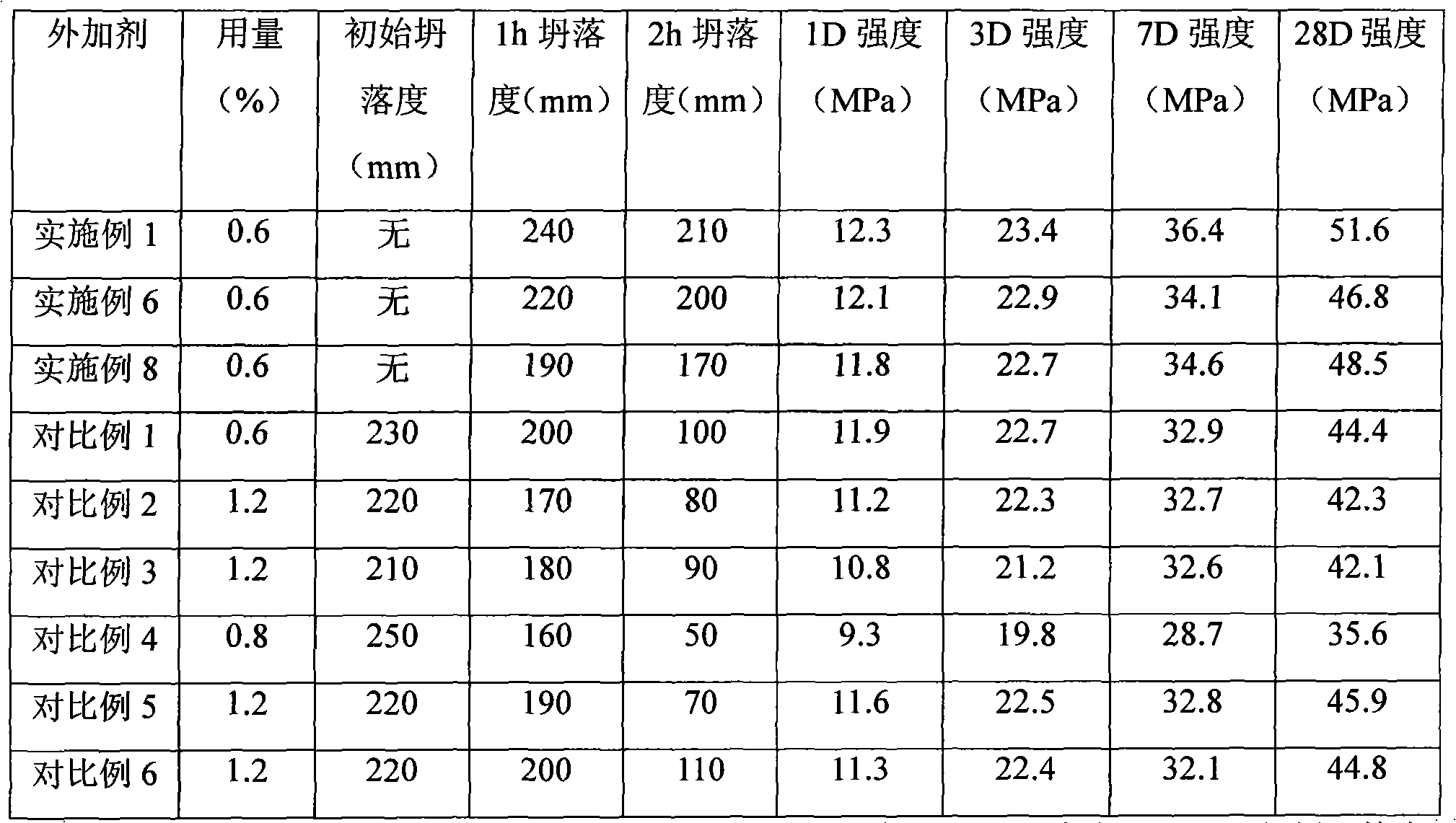

Examples

Embodiment 1

[0025] 1068 parts of methoxypolyethylene glycol MPEG1000 methacrylate (macromonomer), 258 parts of methacrylic acid, 10 parts of thioglycolic acid and 1500 parts of water are made into monomer aqueous solution, and 10 parts of ammonium persulfate are dissolved in 90 10% aqueous initiator solution was prepared with water. Add 550 parts of water into the reaction kettle, heat to 80°C, and add the above monomer aqueous solution and initiator aqueous solution dropwise at the same time. During the dropwise addition, the temperature was maintained, and the dropwise addition was completed in 4 hours. The reaction was continued for 30 minutes to obtain the assembly precursor.

[0026] Lower the temperature of the above-mentioned assembly precursor to 60°C, add 10 parts of the assembly agent tetramethylethylenediamine, stir and react for 6 hours, neutralize with 120 parts of 40% aqueous sodium hydroxide solution, lower the temperature, and obtain a slow-release polycarboxylic acid wat...

Embodiment 2

[0028] 1000 parts of polyethylene glycol allyl ether XPEG1000 (macromonomer), 392 parts of methacrylic acid, 10 parts of thioglycolic acid and 1800 parts of water are made into monomer aqueous solution, and 10 parts of ammonium persulfate are dissolved in 90 parts of water to prepare into a 10% aqueous initiator solution. Add 550 parts of water into the reaction kettle, heat to 80°C, and add the above monomer aqueous solution and initiator aqueous solution dropwise at the same time. During the dropwise addition, the temperature was maintained, and the dropwise addition was completed in 4 hours. The reaction was continued for 30 minutes to obtain the assembly precursor.

[0029] Lower the temperature of the above-mentioned assembly precursor to 60°C, add 10 parts of the assembly agent tetramethylethylenediamine, stir and react for 6 hours, neutralize with 120 parts of 40% aqueous sodium hydroxide solution, lower the temperature, and obtain a slow-release polycarboxylic acid wa...

Embodiment 3

[0031] 1068 parts of methoxypolyethylene glycol MPEG1000 methacrylate (macromonomer), 258 parts of acrylic acid, 5 parts of thioglycolic acid and 1500 parts of water are made into monomer aqueous solution, and 10 parts of ammonium persulfate are dissolved in 90 parts of water Dubbed 10% initiator aqueous solution. Add 550 parts of water into the reaction kettle, heat it to 70°C, and add the above monomer aqueous solution and initiator aqueous solution dropwise at the same time. During the dropwise addition, the temperature was maintained, and the dropwise addition was completed in 4 hours. The reaction was continued for 30 minutes to obtain the assembly precursor.

[0032] Cool the above assembly precursor to 60°C, add 15 parts of assembling agent tetraethylhexamethylenediamine, stir and react for 30 minutes, neutralize with 120 parts of 40% aqueous sodium hydroxide solution, lower the temperature, and obtain slow-release polycarboxylic acid water-reduced agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com