Method for processing vulcanized hydrogenation catalyst

A hydrogenation catalyst and vulcanization-type technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of high vulcanization cost, high preparation cost, flammability, etc., and simplify the production process , the preparation method is simple, and the effect of improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the sulfurized hydrogenation catalyst of the present invention can adopt the following three specific processes.

[0028] 1. Impregnating the active metal first, and then treating it with a vulcanizing agent solution.

[0029] (1) dissolving Group VIII and Group IVB metal inorganic salts in an acidic or alkaline solution to form a solution of the desired concentration;

[0030] (2) impregnating the catalyst carrier with the solution prepared in step (1) by a saturated impregnation method or an excess impregnation method, and drying at 20-200° C. for 1-10 hours;

[0031] (3) impregnating the material obtained in step (2) with a vulcanizing agent aqueous solution using a saturated impregnation method or an excessive impregnation method; the pH value of the solution can be adjusted to 4 to 11 to make the vulcanization reaction complete;

[0032] (4) The material obtained in step (3) is dried at 20-200° C. for 1-10 hours.

[0033] 2. First impreg...

Embodiment 1

[0044] a) Preparation of catalyst support

[0045] Take by weighing 900g of pseudo-boehmite (produced by Shandong Aluminum Oxidation Factory, dry basis is 73%), 19g of scallop powder, 32g of citric acid, 48ml of nitric acid (30%), 159ml of silica gel (containing 30% of silicon dioxide), remove 250ml of deionized water was mixed evenly, extruded into 1.2mm clover strips on an extruder, and roasted at 600°C for 3 hours to obtain carrier A. The main physical properties are shown in Table 1.

[0046] b) Preparation of sulfurized hydrogenation catalyst B

[0047] Weigh 28.48g of molybdenum oxide, 8.9g of basic nickel carbonate, add 60ml of deionized water and mix well, add 4ml of 85% phosphoric acid, heat to 75°C, and keep the temperature for 1 hour to obtain a dark green clear and transparent solution, then add 30.2g of partial tungsten Stir the ammonium acid to obtain the impregnating solution 1 after dissolving. Measure the soaking solution 1 according to the water absorption ...

Embodiment 2

[0051] a) Preparation of sulfurized hydrogenation catalyst C

[0052] Get impregnation solution 1 and ammonium sulfide among the embodiment 1 and press water absorption rate 74ml / 100g and flow spray impregnation carrier A, the volume ratio of impregnation solution 1 and ammonium sulfide is 1: 1, promptly obtains catalyst C in 100 ℃ of drying 3 hours, The main physical properties are listed in Table 1.

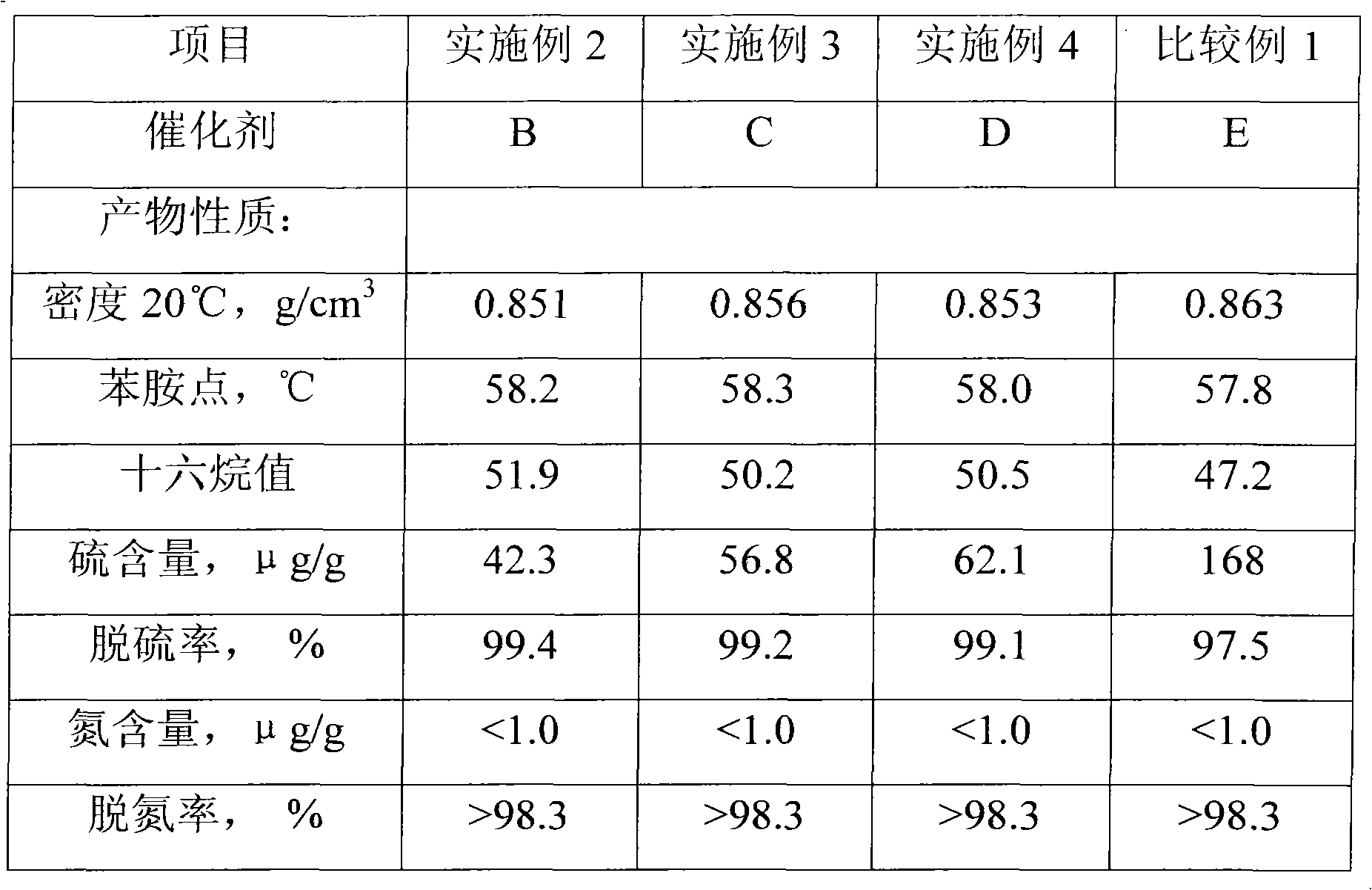

[0053] b) The catalyst start-up method and evaluation are the same as in Example 1. See Table 2 for the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com