Palonosetron hydrochloride orally disintegrating tablet and preparation method thereof

A technology of palonosetron hydrochloride and orally disintegrating tablets, which is applied in the field of palonosetron hydrochloride orally disintegrating tablets and its preparation, can solve the problems not related to orally disintegrating tablets, and reach the disintegration time limit quickly , More absorption points, less sandy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

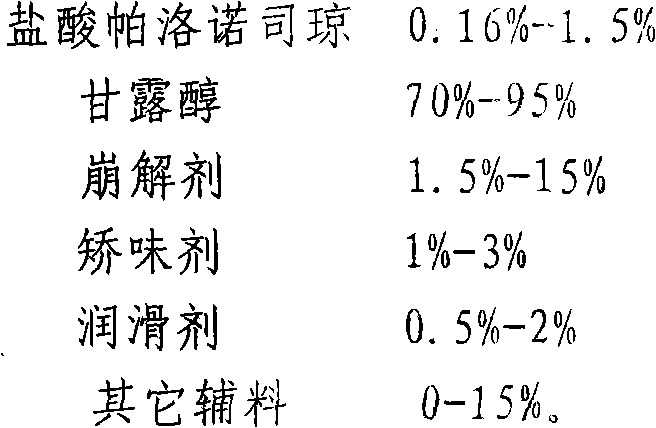

[0036] Palonosetron hydrochloride orally disintegrating tablets are prescribed as:

[0037]

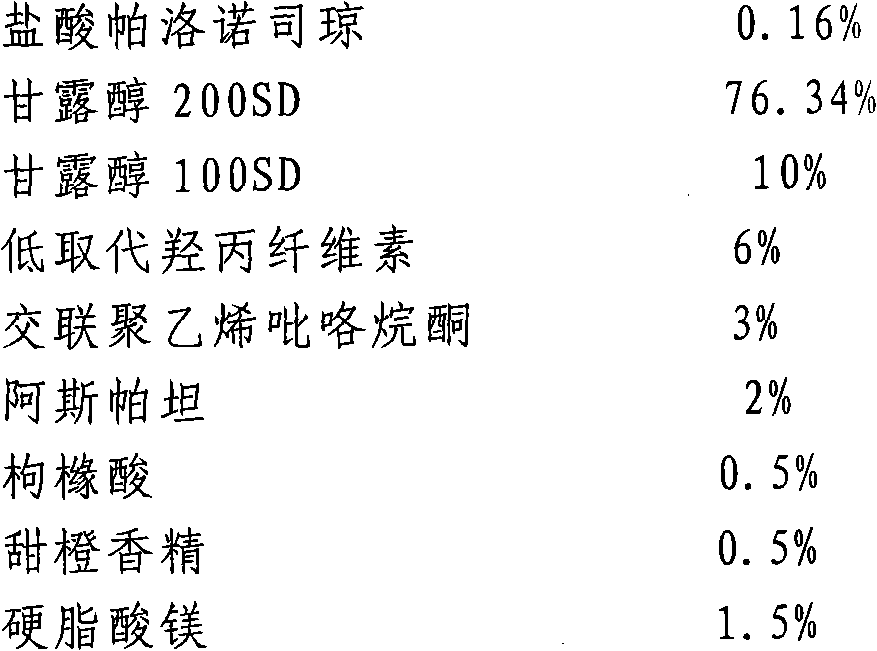

[0038] Preparation: The dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by direct compression process. The specific preparation method is as follows: sweet orange essence, citric acid, aspartame, palonosetron hydrochloride, low-substituted hydroxypropyl Cellulose and cross-linked polyvinylpyrrolidone were finely ground and passed through 80 mesh sieve, and mixed uniformly to obtain mixture A; mannitol 200SD and mannitol 100SD were respectively passed through 40 mesh sieve, weighed according to the amount, and mixed uniformly to obtain mixture B: Mixture B is added to mixture A in an equal amount increasing manner to obtain mixture C. Then add the magnesium stearate of prescription quantity, sieve and mix, carry out intermediate content detection. After determining the weight of the tablet, the tablet is compressed by direct compression tech...

Embodiment 2

[0040] Palonosetron hydrochloride orally disintegrating tablets are prescribed as:

[0041]

[0042]

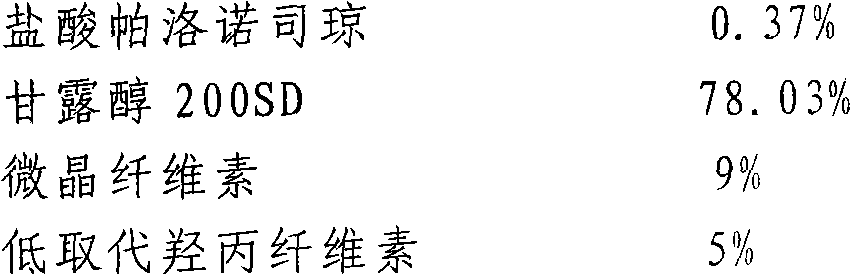

[0043] Preparation: The dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by direct compression process. The specific preparation method is as follows: sweet orange essence, citric acid, aspartame, palonosetron hydrochloride, low-substituted hydroxypropyl Cellulose and croscarmellose sodium were respectively ground and passed through 80 mesh sieves, and mixed uniformly to obtain mixture A; mannitol 200SD and microcrystalline cellulose were respectively passed through 40 mesh sieves, weighed respectively, and made Mix evenly to obtain mixture B; add mixture B to mixture A in an equal and incremental manner to obtain mixture C. Then add the prescribed amount of talcum powder, sieve and mix evenly, and detect the intermediate content. After determining the weight of the tablet, the tablet is compressed by direct compression technolog...

Embodiment 3

[0045] Palonosetron hydrochloride orally disintegrating tablets are prescribed as:

[0046]

[0047] Preparation: Grind assorted flavors, aspartame, palonosetron hydrochloride, and crospovidone separately and pass through a 80-mesh sieve, and mix them uniformly to obtain mixture A; Weigh to obtain B; add the prescribed amount of B to mixture A by means of equal increments to obtain mixture C. Then add the colloidal silicon dioxide and calcium stearate of the prescription amount, sieve and mix, and carry out the detection of the intermediate content. After determining the weight of the tablet, the tablet is compressed by direct compression technology, and the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

| friability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com