Method for preparing superparamagnetic polymer microspheres

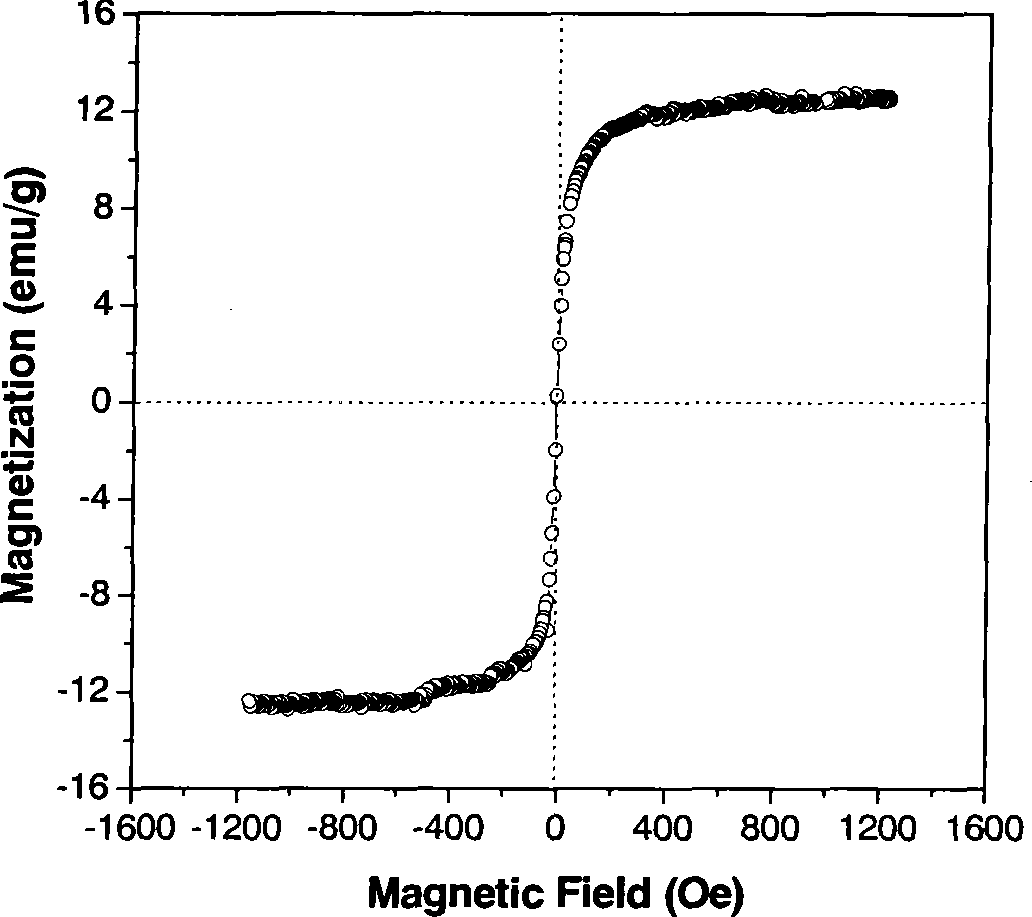

A superparamagnetic and polymer technology, applied in the field of polymer materials, can solve the problems of difficult control of microsphere particle size and magnetic content, complex preparation process of magnetic polymer microspheres, etc., and achieve easy expansion of production, size and magnetic content Controllable, high saturation magnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 10.8g FeCl 3 Add 36.5g of sodium oleate and 36.5g of sodium oleate into a 500ml flask, add 80ml of absolute ethanol and 140 n-hexane into the flask, after dissolving, heat at 70°C for 4h, wash the resulting black solution with deionized water for 3 to 4 times, and dry it in vacuum at 50°C Dry in the box for 24 hours to obtain hydrophobic iron oleate.

Embodiment 2

[0036] Take 16g of ferric sulfate and 37g of sodium oleate into a 500ml flask, add 80ml of absolute ethanol and 140 of n-hexane into the flask, after dissolving, heat at 70°C for 4h, wash the obtained black solution with deionized water 3 to 4 times, 50 °C in a vacuum oven for 24 hours to obtain hydrophobic iron oleate.

[0037] 2. Synthesis of polymer microspheres:

Embodiment 3

[0039] Synthesis of polystyrene microspheres by soap-free emulsion polymerization:

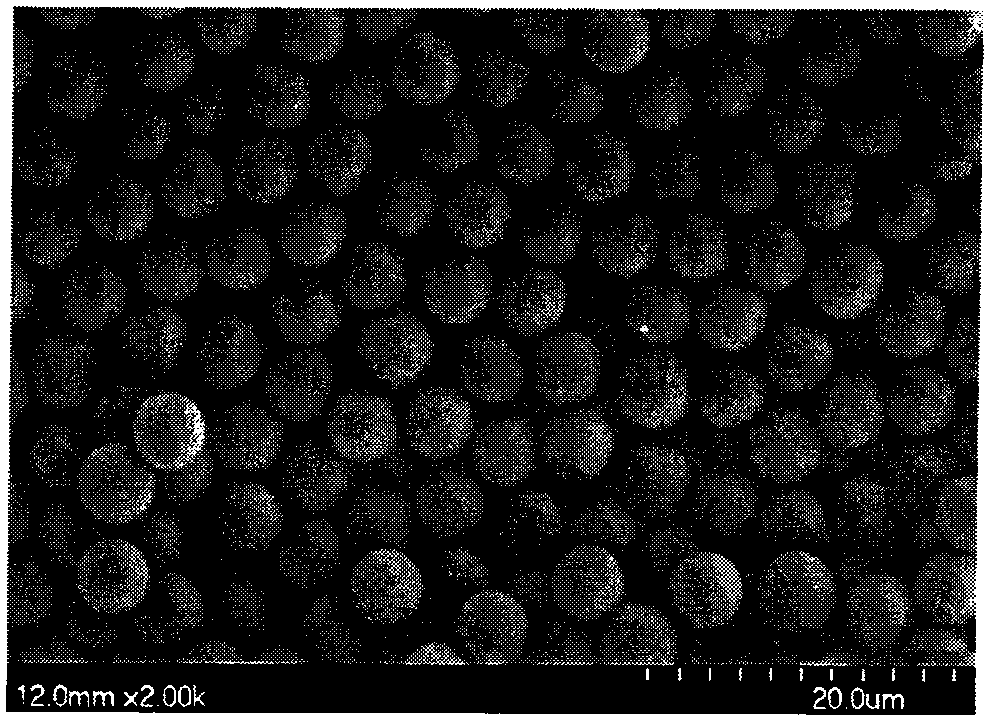

[0040] Add 620ml of deionized water and 1g of NaCl into the reactor, and after being dissolved, move it into a constant temperature water bath at 60°C, stir nitrogen for 10min, then add 65g of styrene monomer and 1.3g of crosslinking agent divinylbenzene, Continue stirring nitrogen for 30min. Then 0.65 g of potassium persulfate (KPS) was added, and after 24 h at 60° C., cooled to room temperature, the polymer emulsion was centrifuged to obtain polystyrene microspheres, which were washed repeatedly with deionized water. The product was dried under vacuum at room temperature for further use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com