Device for purifying polysilicon by shell melting method, and method

A polycrystalline silicon and solar-grade technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of slow flow rate of silicon melt, slow impurity removal rate, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

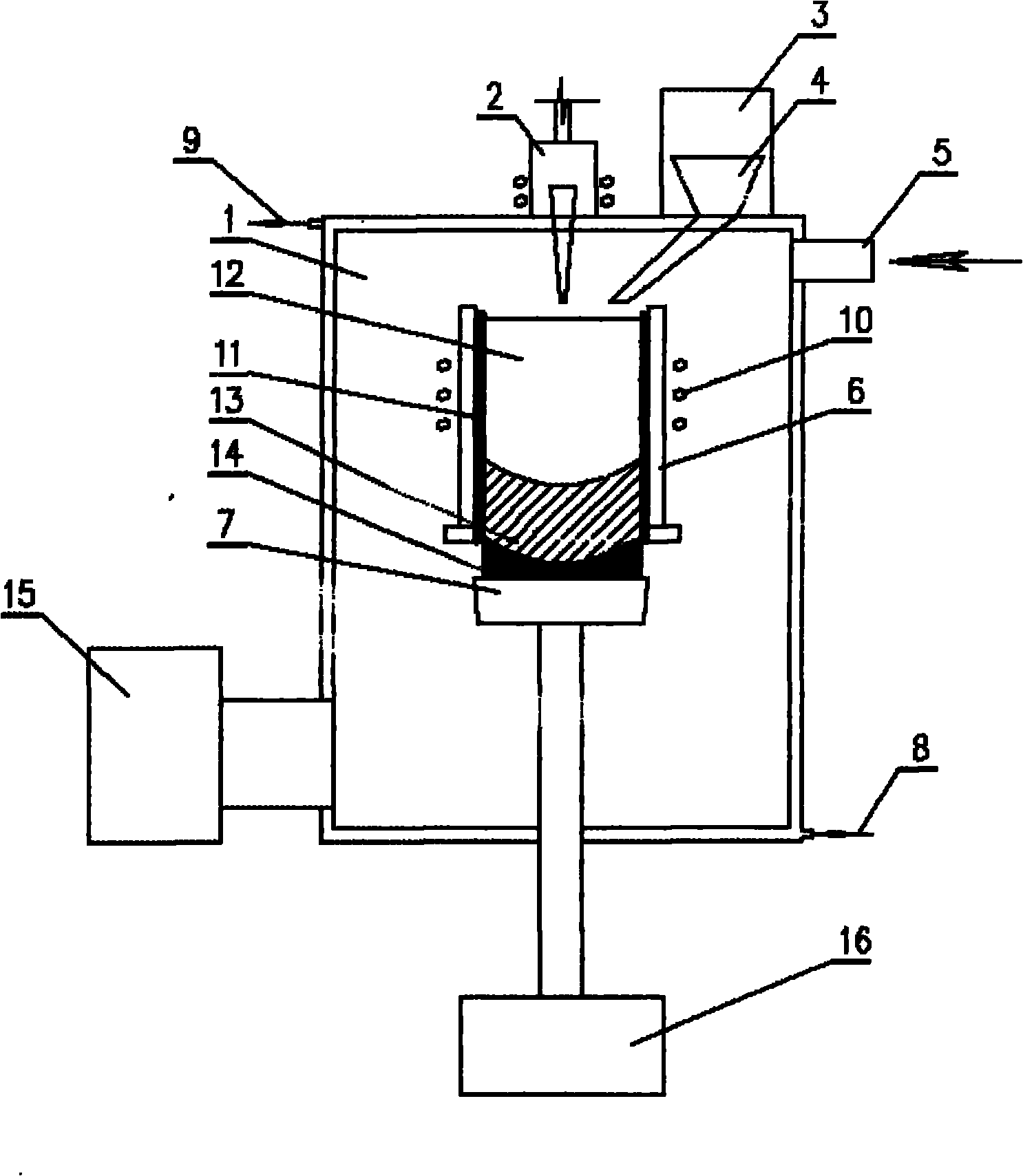

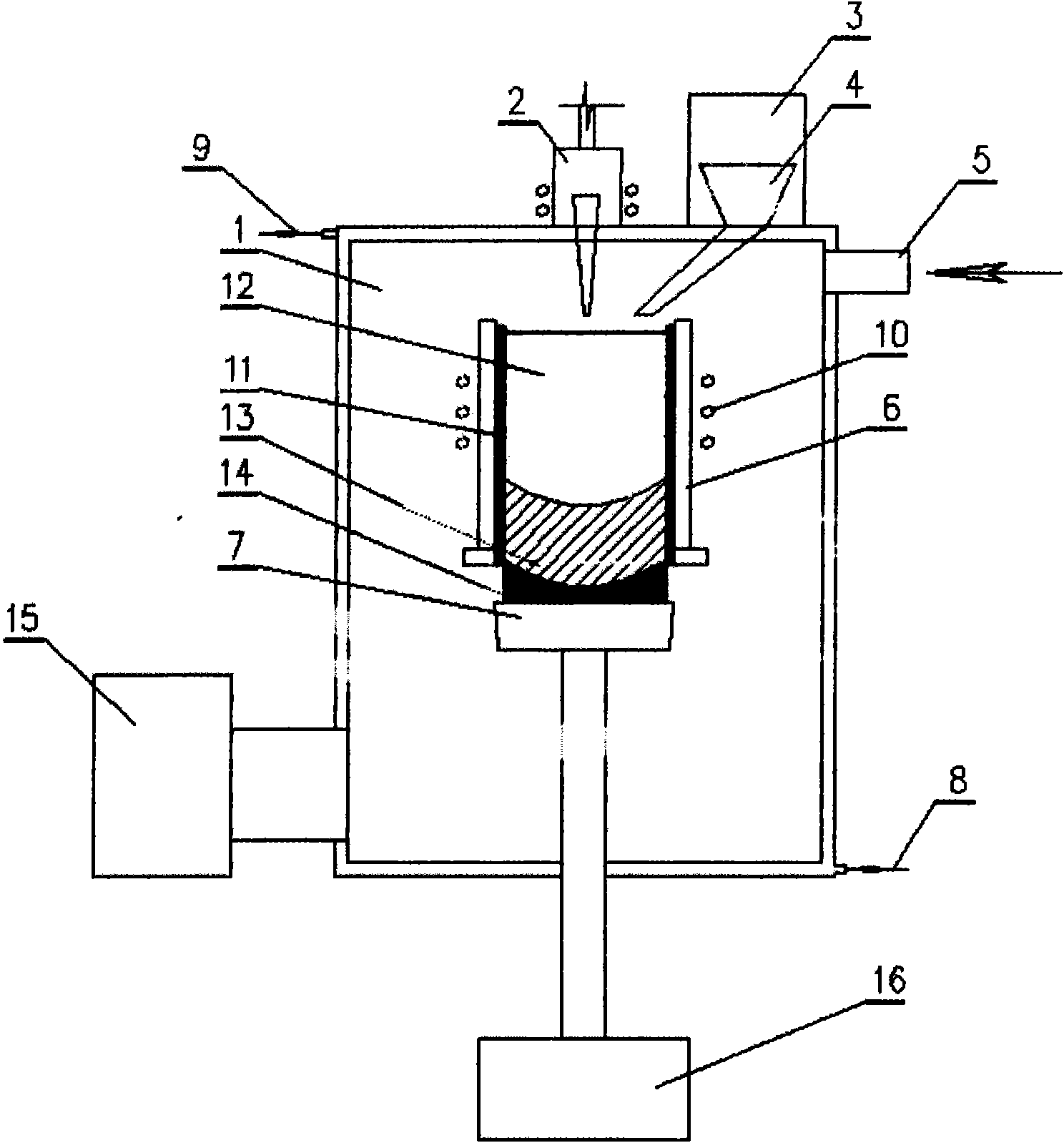

[0040] 1. Form a melting shell crucible and melt the polysilicon raw material in it:

[0041] Raise the water-cooled chassis to the lower edge of the annular water-cooled copper tube, and then apply silicon powder slurry with a purity of 4N on the annular water-cooled copper tube and the water-cooled chassis to form a container, and load 4N polysilicon blocks to the upper edge of the copper tube.

[0042] Vacuum the furnace to 10 -3 Pa, filled with argon flow for 10 minutes; then start the argon plasma spray gun, ionization frequency 3MHz, power 60KW, melt a molten pool in the upper center of the polysilicon block, when the diameter of the molten pool reaches 20mm or more, start the ultra-high frequency induction The heating coil is directly coupled with the silicon molten pool and the power is gradually increased. The induction heating frequency is 1.3MHz and the power is 200KW to gradually expand the silicon molten pool. At the same time, the feeder is continuously fed unt...

Embodiment 2

[0053] 1. Form a melting shell crucible and melt the polysilicon raw material in it:

[0054] Raise the water-cooled chassis to the lower edge of the annular water-cooled copper tube, and then apply silicon powder slurry with a purity of 6N on the annular water-cooled copper tube and the water-cooled chassis to form a container, and load 4N polysilicon blocks to the upper edge of the copper tube.

[0055] Vacuum the furnace to 10 -3 Pa, filled with argon flow for 20 minutes; then start the argon plasma spray gun, ionization frequency 3.5MHz, power 100KW, melt a molten pool in the upper center of the polysilicon block, when the diameter of the molten pool reaches 20mm or more, start the ultra-high frequency The induction heating coil is directly coupled with the silicon molten pool and the power is gradually increased. The induction heating frequency is 1.8MHz and the power is 200KW, so that the silicon molten pool is gradually expanded, and the feeder is continuously fed unt...

Embodiment 3

[0066] 1. Form a melting shell crucible and melt the polysilicon raw material in it:

[0067] Raise the water-cooled chassis to the lower edge of the annular water-cooled copper tube, and then apply silicon powder slurry with a purity of 6N on the annular water-cooled copper tube and the water-cooled chassis to form a container, and load AN polysilicon blocks to the upper edge of the copper tube.

[0068] Vacuum the furnace to 10 -3 After Pa, fill with argon gas and flow for 30 minutes; then start the argon plasma spray gun with an ionization frequency of 4.5MHz and a power of 100KW to melt a molten pool in the upper center of the polysilicon block. When the diameter of the molten pool reaches 20mm or more, start the ultra-high frequency The induction heating coil is directly coupled with the silicon molten pool and the power is gradually increased. The induction heating frequency is 2.5MHz and the power is 300KW to gradually expand the silicon molten pool. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com