Luminous enhanced terbium-doped nano microcrystalline glass and preparation method thereof

A technology of luminescence enhancement and nano-crystallite, which is applied in the field of luminescent materials, can solve problems such as insufficient luminous intensity and obstruction of luminous intensity, and achieve the effects of avoiding concentration quenching effect, facilitating absorption, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use an analytical balance to weigh 0.590g of analytically pure calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and 0.113g of analytically pure terbium nitrate hexahydrate (Tb(NO 3 ) 3 ·6H 2 O) dissolved in 10ml of distilled water, prepared to contain Ca concentration of 0.25mol / L 2+ and 0.025mol / L of Tb 3+ mixed solution. Soak the nano-microporous glass in the mixed solution for 3 hours, take it out, let it dry at room temperature, and then place it in a high-temperature furnace. The speed is raised to 900°C, and then raised to 1150°C at a speed of 5°C / min, and sintered at 1150°C for 2 hours. The sintered glass is cooled to room temperature with the furnace and taken out. After cutting and polishing, the luminescent glass of the present invention is prepared. Enhanced terbium-doped nanoglass-ceramics.

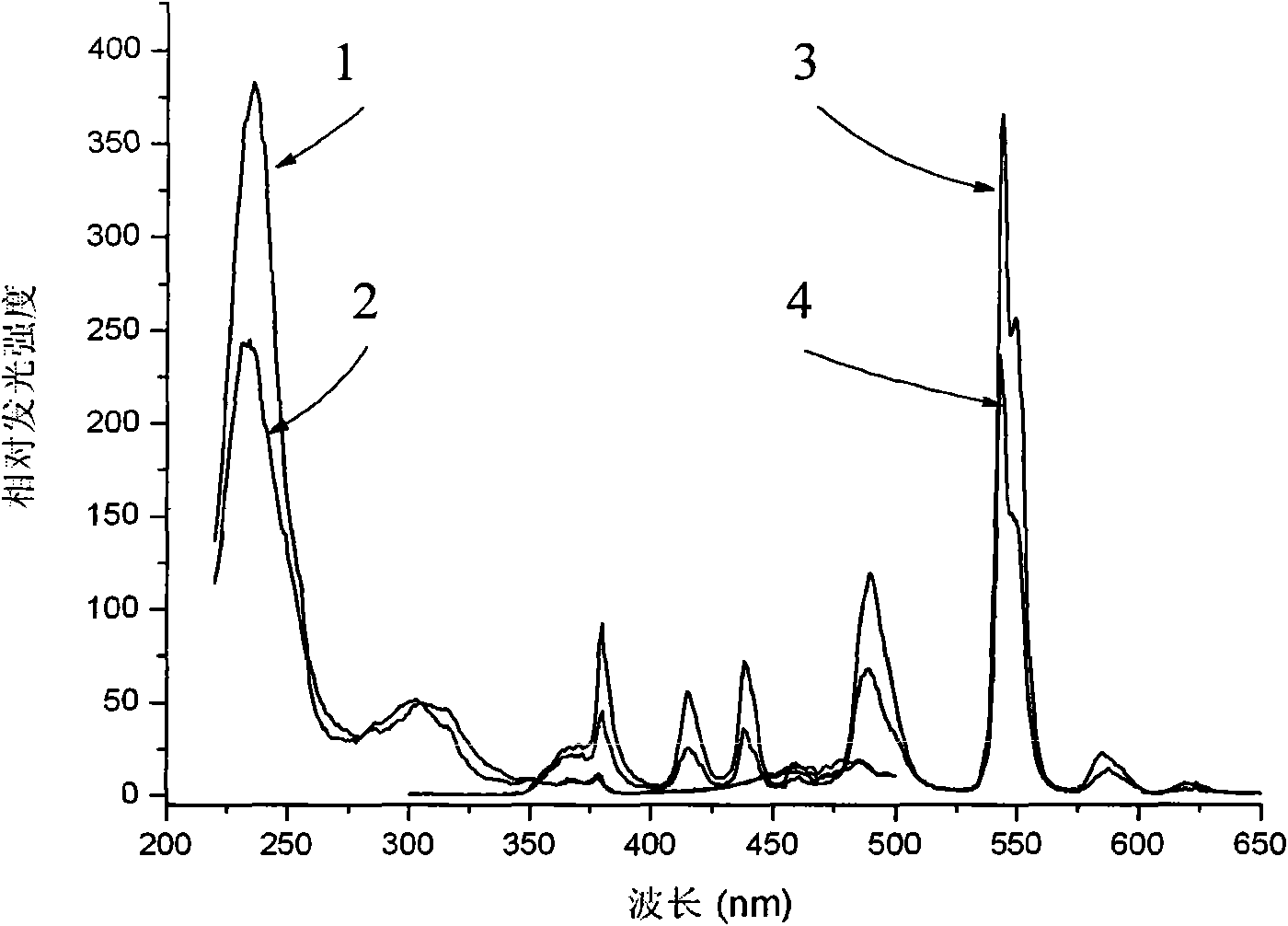

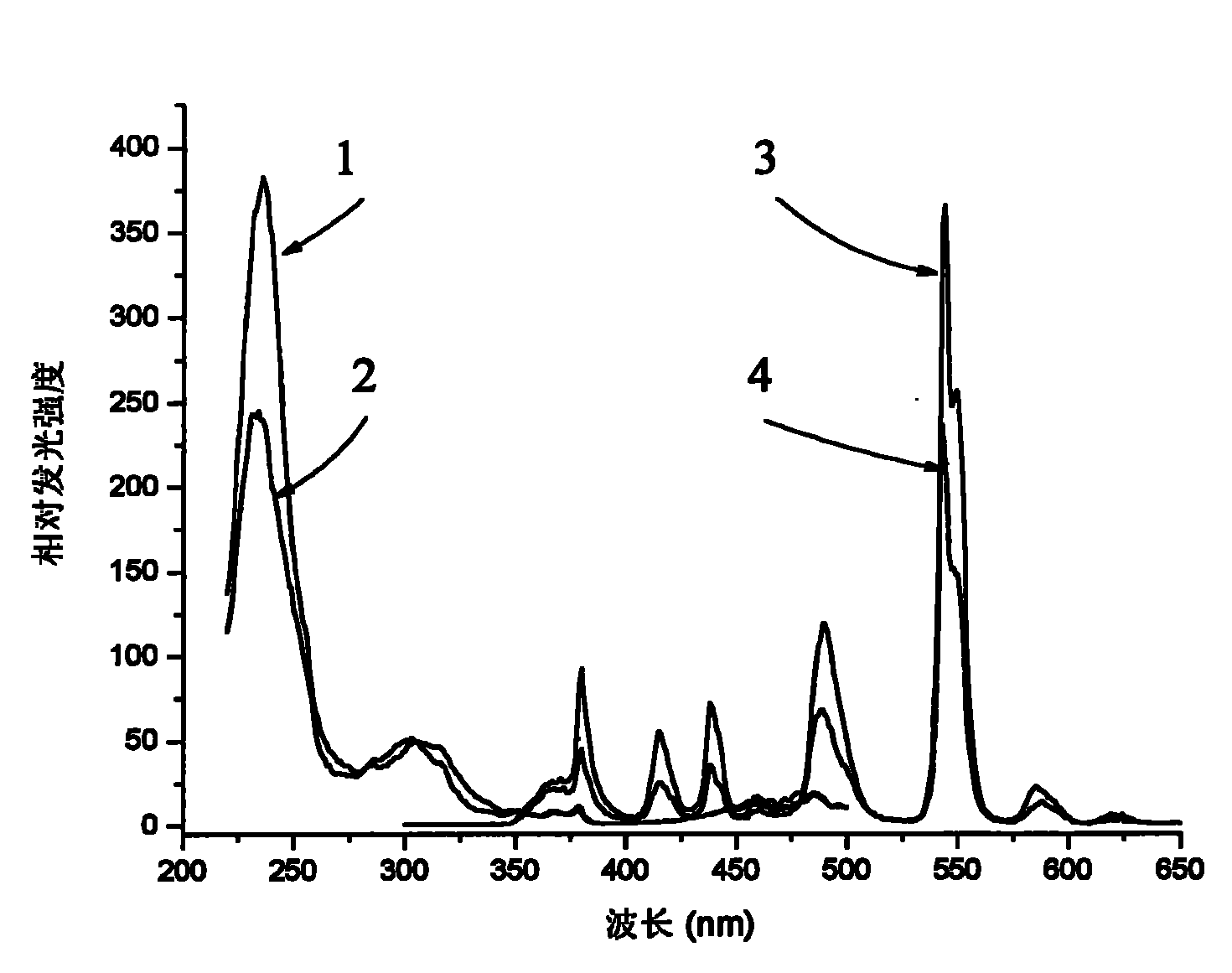

[0033] figure 1 The comparison diagram of the excitation and emission spectra of the luminescence-enhanced terbium-doped nanocrystalline glass-ceramics prepar...

Embodiment 2

[0035] Use an analytical balance to weigh 0.529g of analytically pure strontium nitrate (Sr(NO3 ) 2 ) and 0.113g of analytically pure terbium nitrate hexahydrate (Tb(NO 3 ) 3 ·6H 2 O) Dissolved in 10ml of distilled water, prepared to contain Sr at a concentration of 0.25mol / L 2+ and 0.025mol / L of Tb 3+ mixed solution. Soak the nano-microporous glass in the mixed solution for 3 hours, take it out, let it dry at room temperature, and then place it in a high-temperature furnace. The speed is raised to 900°C, and then raised to 1150°C at a speed of 5°C / min, and sintered at 1150°C for 2 hours. The sintered glass is cooled to room temperature with the furnace and taken out. After cutting and polishing, the luminescent glass of the present invention is prepared. Enhanced terbium-doped nanoglass-ceramics.

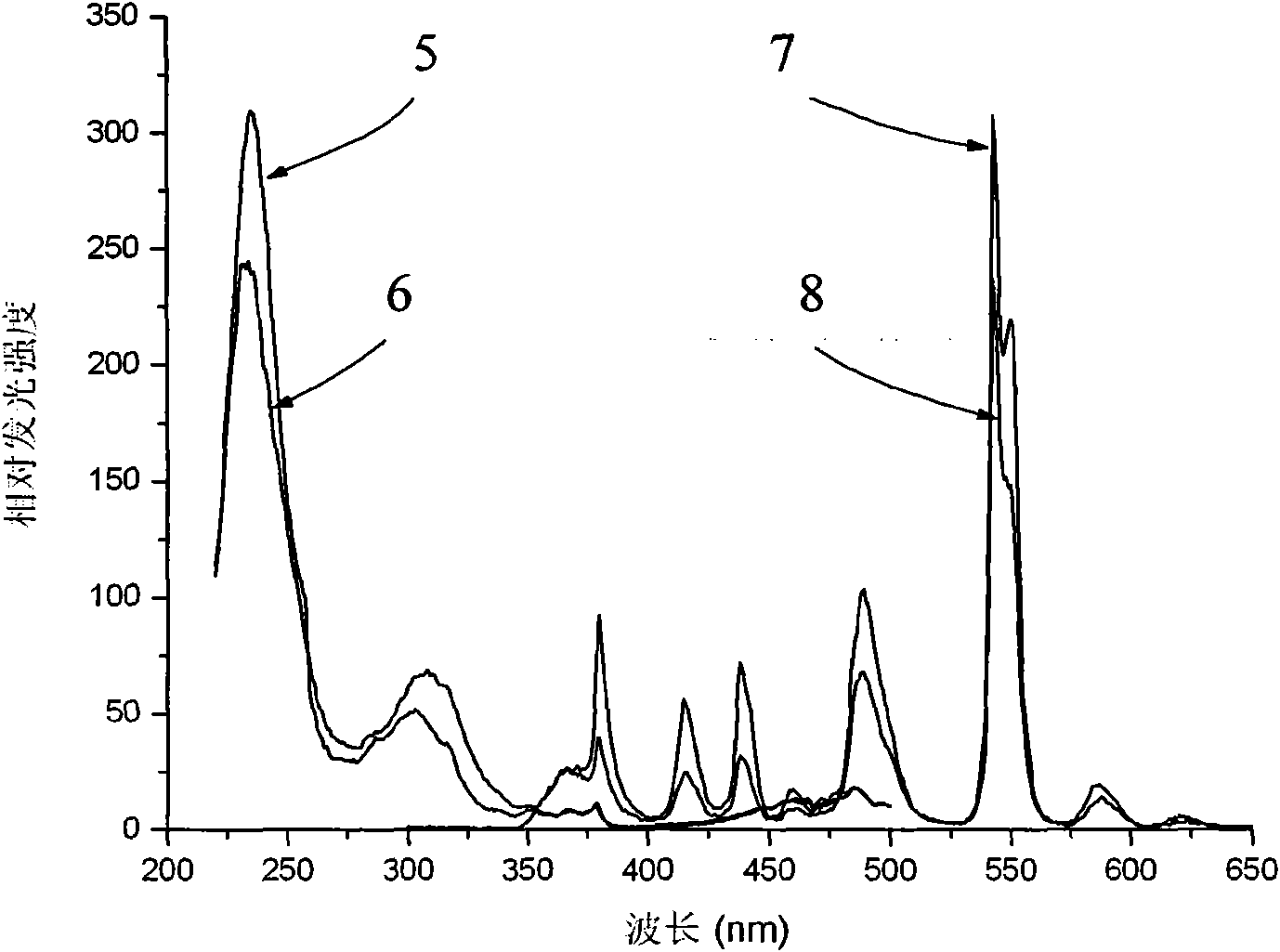

[0036] figure 2 The comparison diagram of the excitation and emission spectra of the luminescence-enhanced terbium-doped nanocrystalline glass-ceramics prepared for this ex...

Embodiment 3

[0038] Use an analytical balance to weigh 0.653g of analytically pure barium nitrate (Ba(NO 3 ) 2 ) and 0.113g of analytically pure terbium nitrate hexahydrate (Tb(NO 3 ) 3 ·6H 2 O) be dissolved in the distilled water of 10ml, be prepared to contain the Ba that concentration is 0.25mol / L 2+ and 0.025mol / L of Tb 3+ mixed solution. Soak the nano-microporous glass in the mixed solution for 2 hours, take it out, let it dry at room temperature, and place it in a high-temperature furnace. The speed is raised to 900°C, and then raised to 1150°C at a speed of 5°C / min, and sintered at 1150°C for 2 hours. The sintered glass is cooled to room temperature with the furnace and taken out. After cutting and polishing, the luminescent glass of the present invention is prepared. Enhanced terbium-doped nanoglass-ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com