Method for preparing dimethylamino propylamine through hydrogenating dimethylamino propionitrile in presence of nickel

A technology for catalyzing dimethylaminopropionitrile and dimethylaminopropionitrile is applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., and achieves the improvement of selectivity, activity and selectivity, and reduction of operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

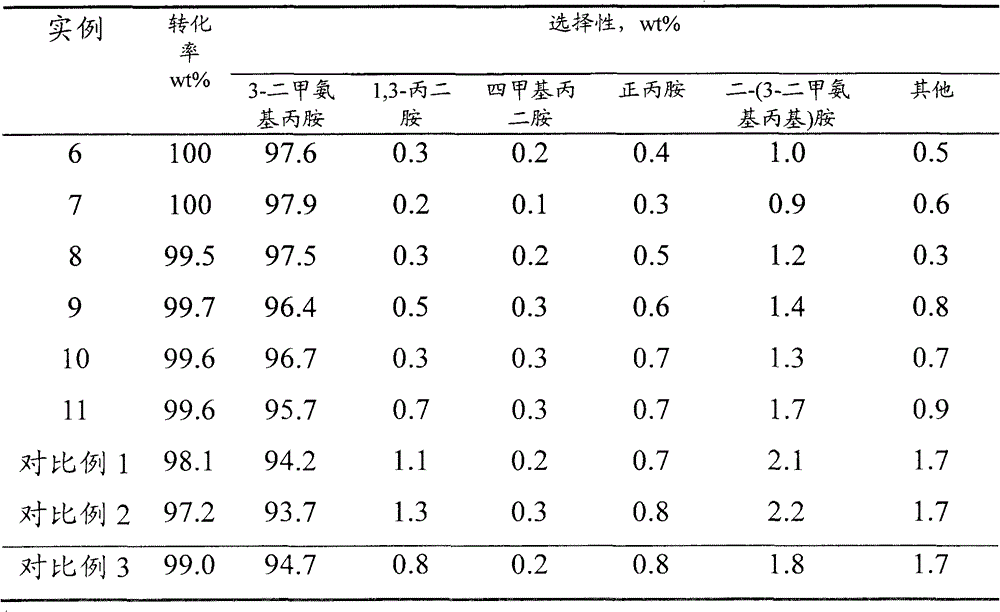

Examples

Embodiment 1

[0015] 1.5kg nickel, 1.0kg aluminum, 0.4kg Mo 10 Al 90 Add the alloy and 0.1kg cobalt into the graphite crucible, heat it in a high-frequency furnace until it melts, and then spray the molten liquid from the nozzle of the crucible onto a nickel roller with a rotation speed of 600 to 1000 rpm. Cooling water and alloy liquid are rapidly cooled at a cooling rate of 1000°C / s and then thrown out along the tangent line of the nickel roll to form scale-like strips, which are ground to a particle diameter of less than 70 microns to obtain a master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20 wt % sodium hydroxide aqueous solution, control its temperature at 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, the liquid was filtered off and washed with distilled water at 100°C until the pH value was 7. The prepared catalyst is numbered Catalyst-1, and the composition of Catalyst-1 is shown in ...

Embodiment 2

[0017] 1.5kg nickel, 1.0kg aluminum, 0.4kg Mo 5 Al 95 Add the alloy and 0.1kg iron into the graphite crucible, heat it in a high-frequency furnace until it melts, and then the molten liquid is sprayed from the nozzle of the crucible onto a nickel roller with a rotation speed of 900 rpm, and cooling water is passed through the nickel roller , the alloy liquid is rapidly cooled at a cooling rate of 1000°C / s, and then thrown out along the tangent line of the nickel roller to form scale-like strips, which are ground to a particle diameter of less than 70 microns to obtain a master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20 wt % sodium hydroxide aqueous solution, control its temperature at 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catalyst-2, and the composition of...

Embodiment 3

[0019] 1.2kg nickel, 1.0kg aluminum, 0.5kg Mo 10 Al 90 Add the alloy and 0.3kg manganese into the graphite crucible, heat it in a high-frequency furnace until it melts, spray the melt from the nozzle of the crucible onto a nickel roller with a rotation speed of 900 rpm, and pass cooling water through the nickel roller , the alloy solution is 1×10 5 After rapid cooling at the cooling rate of ℃ / s, it is thrown out along the tangent line of the nickel roll to form scale-like strips. The scale-like strips are ground to a particle diameter of less than 70 microns to obtain a master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20 wt % sodium hydroxide aqueous solution, control its temperature at 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catalyst-3, and the composition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com