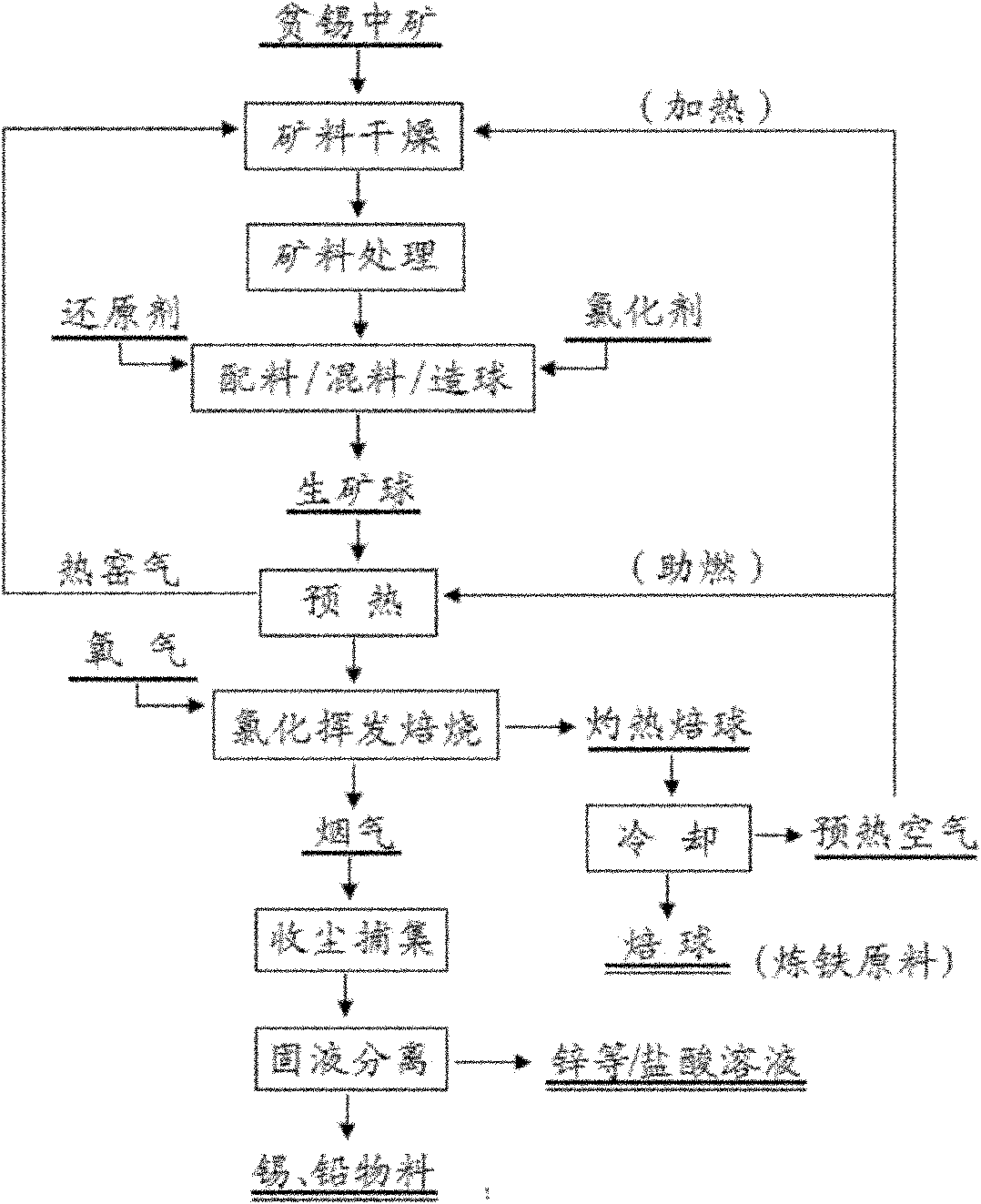

Method for treating enrichment set in poor pin and extracting tin and other color metals

A technology for non-ferrous metals and valuable metals, which is used in the field of processing tin-poor ore enrichment and extraction of tin and other non-ferrous metals, which can solve the problems of complex ore properties and reduced ore beneficiation recovery rate, etc., to strengthen the chlorination process and reduce equipment. Processing load, effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The tin-poor medium ore is processed and passed through a 60-mesh sieve; the ore content is 7-8% CaCl 2 , 3 ~ 4% pulverized coal, pelletizing; preheat to 700 ~ 750 ℃. The hot material enters the rotary kiln for mixing and chlorination roasting; pulverized coal is used as fuel and oxygen-enriched (preheated to 800°C) to support combustion; the chlorination roasting temperature is 1000-1050°C and the time is 40-50 minutes; the CO in the furnace gas is controlled / CO 2 It is 0.8~1.0; the flue gas is cooled, settled and wet dust collected to recover valuable metals.

[0059] The volatilization rate (%) of each valuable element is: Sn 96.2; Pb 98.4; Zn 71.6; the capture recovery rate (%) of each valuable element is: Sn 91.9; Pb 93.4; Zn 68.1.

Embodiment 2

[0061] The tin-poor medium ore has been processed and passed through a 60-mesh sieve; the amount of ore added is 4-5% CaCl 2 , 4-5% pulverized coal, pelletizing; preheat to 600-650°C. The hot material enters the rotary kiln for mixing and chlorination roasting; pulverized coal is used as fuel and oxygen-enriched (preheated to 800°C) to support combustion; the chlorination roasting temperature is 800-850°C, and the time is 90-100min; the CO in the furnace gas is controlled / CO 2 1.0 to 1.2; the flue gas is cooled, settled and wet dust collected to recover valuable metals.

[0062] The volatilization rate (%) of each valuable element is: Sn 93.4; Pb 95.7; Zn 70.3; the capture recovery rate (%) of each valuable element is: Sn 89.5; Pb 90.4; Zn 66.7.

Embodiment 3

[0064] The tin-poor medium ore has been processed and passed through a 60-mesh sieve; the amount of ore added is 5-6% CaCl 2 , 4-5% pulverized coal, pelletizing; preheat to 650-700°C. The hot material enters the rotary kiln for mixing and chlorination roasting; pulverized coal is used as fuel and oxygen-enriched (preheated to 800°C) to support combustion; the chlorination roasting temperature is 900-950°C, and the time is 70-80 minutes; the CO in the furnace gas is controlled / CO 2 It is ~1.0; the flue gas is cooled, settled and wet dust collected to recover valuable metals.

[0065] The volatilization rate (%) of each valuable element is: Sn 94.9; Pb 97.1; Zn 70.8; the capture recovery rate (%) of each valuable element is: Sn 91.1; Pb 92.7; Zn 67.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com