Dust collecting and waste heat utilizing system for argon oxygen decarburization furnace

An argon-oxygen decarburization furnace and waste heat technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of limited cooling range, easy ash blockage heat exchange, heavy maintenance workload, etc., to achieve energy reuse, no It is easy to burn the cloth bag and the maintenance workload is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

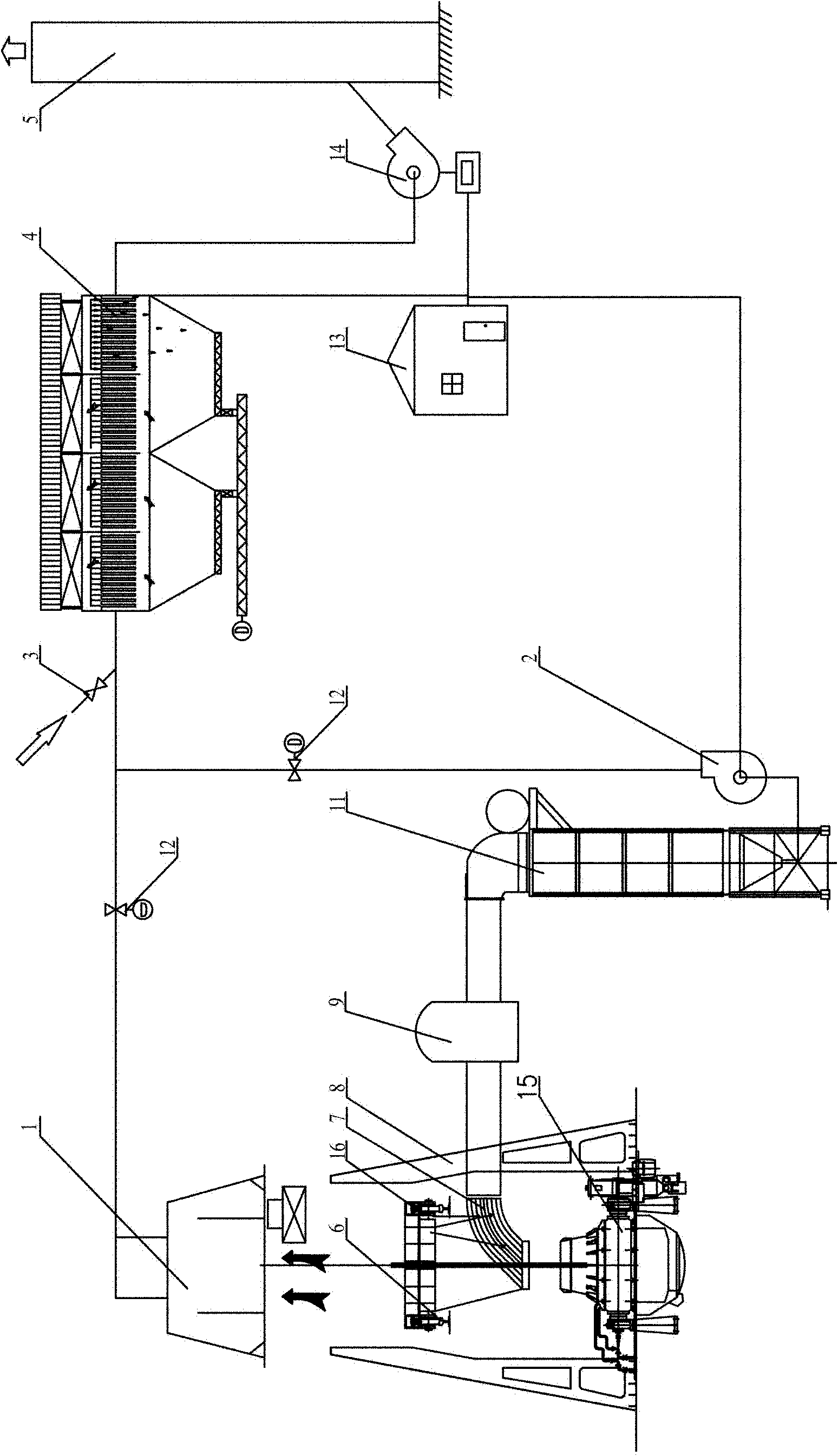

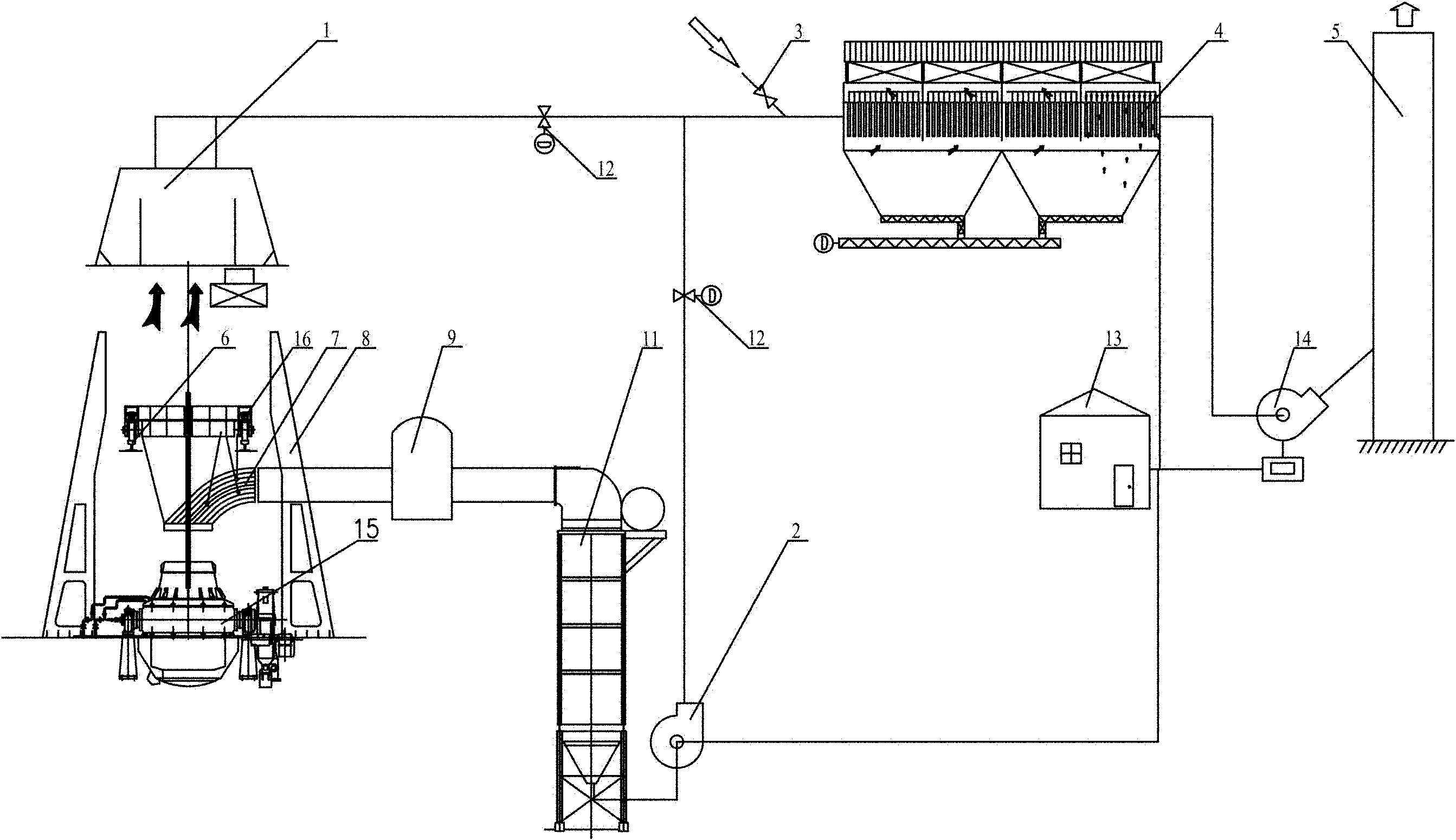

[0021] As shown in the figure: the dust removal and waste heat utilization system of the argon-oxygen decarburization furnace includes a flue gas deflector 8 fixedly installed around the argon-oxygen decarburization furnace 15, and a slide rail 6 is fixed above the argon-oxygen decarburization furnace 15 , a carriage trolley 16 is slidably connected on the slide rail 6, and a variable-flow roof hood 1 is arranged above the slide rail 6, and the exhaust port of the variable-flow roof hood 1 is connected to the air intake of the dust collector 4 through a pipe. port, the exhaust port of dust remover 4 is connected to the inlet port of main fan 14 by pipeline, and the exhaust port of main fan 14 is connected to the inlet port of exhaust cylinder 5 by pipeline; Above argon oxygen decarburization furnace 15, sliding There is a flue gas suction mask 7 under the rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com