Analgesic and repercussive qingpeng plastics and preparation method thereof

A film-coating agent and film-forming agent technology, applied in the field of film-coating agent and its preparation, to achieve better curative effect, improve bioavailability, and long-term effect of drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] According to specific embodiments of the present invention, the preparation method of the present invention may comprise the following steps:

[0077] ① Remove impurities from Oxytropis chinensis, subrhubarb, iron rod hammer, seed myrobalan, myrobalan myrobalan, emblica, benzoin, vine vine, clean and mix;

[0078] ② Weigh 10%-100% of the total weight of the above-mentioned mixed raw materials, decoct 1-4 times with 5-20 times the weight of water, and decoct for 0.5-3 hours each time, collect and combine the extract and volatile oil, filter and Concentrating the extract to form a concentrated solution with a relative density of 1.0-1.5, and adding volatile oil to the concentrated solution to obtain a concentrated solution a;

[0079] Or take 10%-100% of the total weight of the above-mentioned mixed raw materials, and use 5-20 times by weight of 30-90% ethanol to reflux extract 1-4 times, extract 0.5-24 hours each time, collect and combine the extracts, filter After bein...

experiment example 1

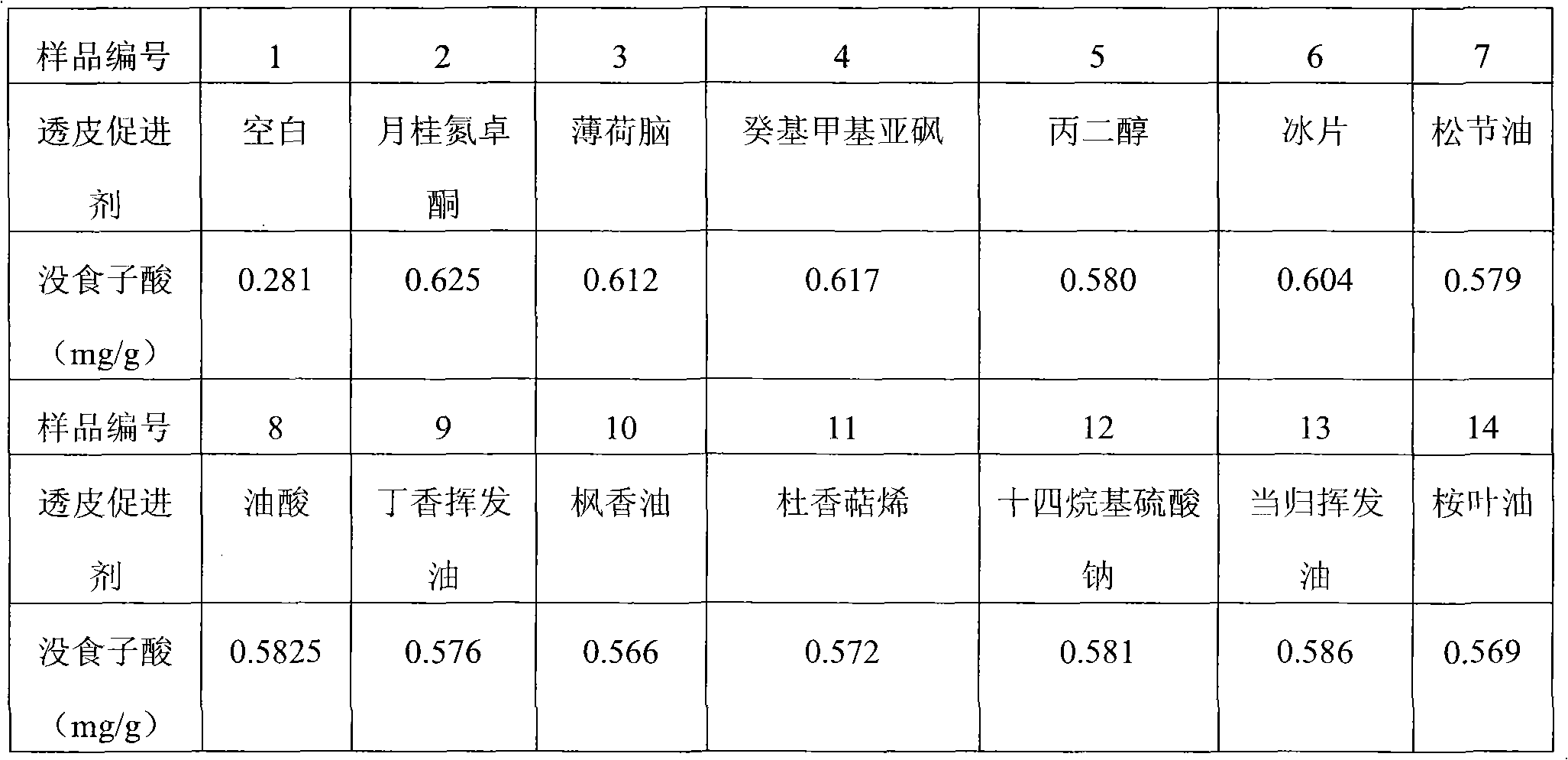

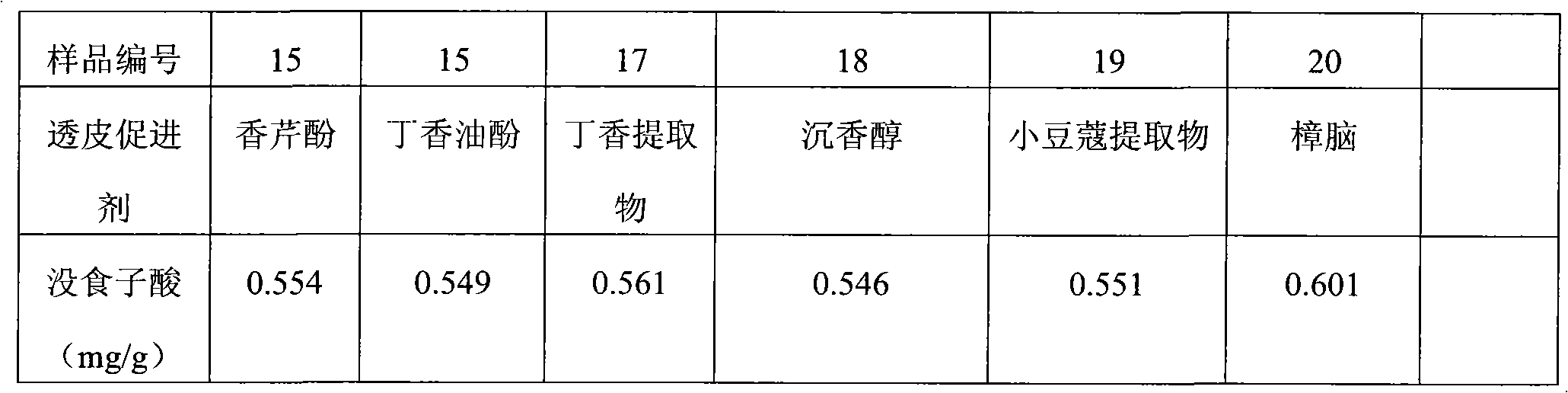

[0147] Experimental example 1: Screening experiment of auxiliary materials of Qingpeng coating agent of the present invention

[0148] 1. Screening experiment of skin penetration enhancer:

[0149] ① Selection of skin penetration enhancer

[0150] Weigh 100g Oxytropis, 50g subrhubarb, 75g iron bar hammer, 100g myrobalan, 100g emblical, 35g benzoin, 150g vine vine, 25g musk; grind musk into fine powder; Use water 10 times the total weight of the materials to decoct twice, decoct for 2.5 hours each time, collect and combine the extract and volatile oil, filter and concentrate the extract into a concentrated solution with a relative density of 1.05-1.15, and add the volatile oil to the concentrated The concentrated solution a is obtained from the liquid; take 300g of polyvinyl alcohol and add distilled water, soak overnight to make it fully swell, slowly add 600ml of ethanol, stir continuously and rapidly while adding, make it fully uniform, then slowly add the above concentrate...

experiment example 2

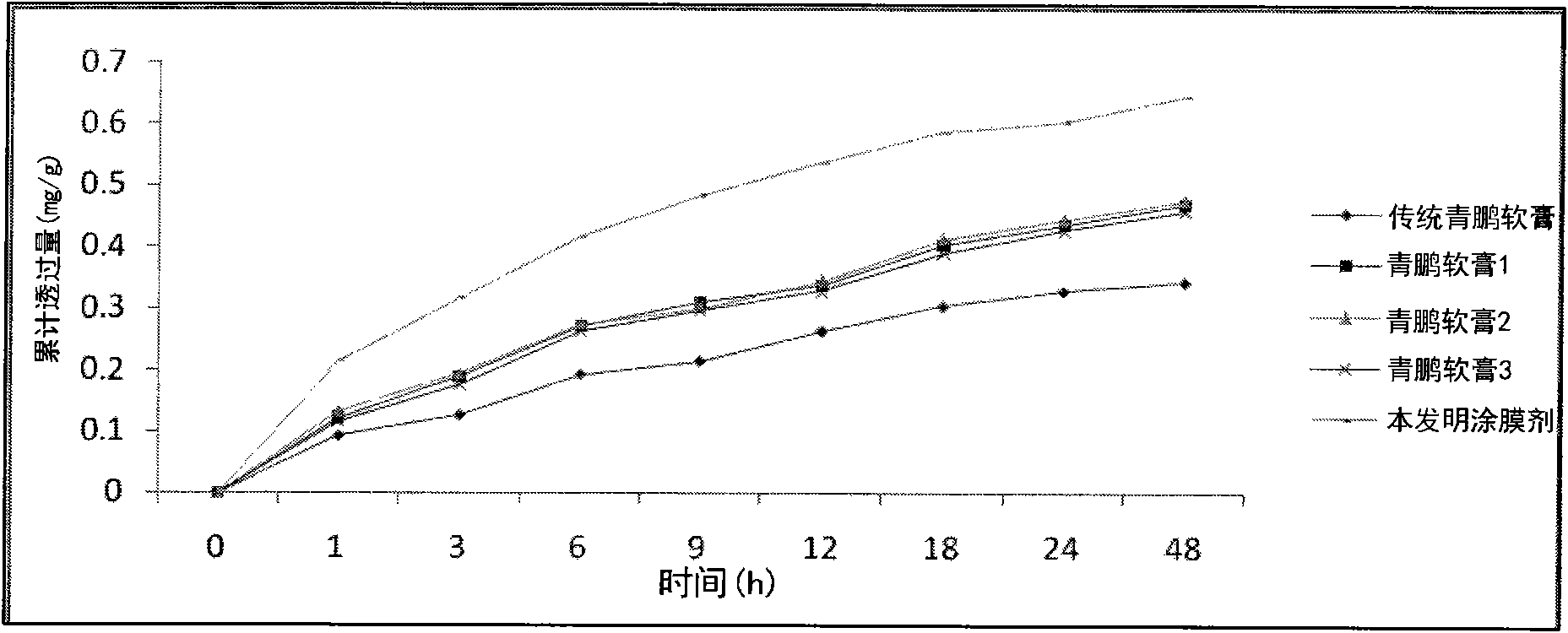

[0179] Experimental example 2: comparative experimental data of Qingpeng film agent of the present invention and Qingpeng ointment action time

[0180] Experimental sample:

[0181] Traditional Qingpeng ointment: provided by Tibet Qizheng Tibetan Medicine Co., Ltd.;

[0182]Qingpeng Ointment 1: Preparation method: ① Purify Oxytropis 100g, Subrhubarb 50g, Iron Bar Hammer 75g, Nucleus myrobalan 100g, Fructus myrobalan 100g, Emlical emblica 100g, benzoin 35g, and vine vine 150g, crush them , mixed evenly, and set aside; ②Weigh 50% of the total weight of the above-mentioned mixed raw materials, use 2.13kg of water, decoct 3 times at 85°C, and decoct for 2 hours each time, collect the extract and volatile oil respectively; filter, Concentrating the extract to a concentrated solution with a relative density of 1.0 to 1.5; adding the volatile oil to the concentrated solution; ③ pulverizing the above-mentioned remaining mixed raw medicine into a 100 μm powder, and mixing it with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com