Decoloring method for recovering cutting fluids through multilineal cutting

A multi-wire cutting and cutting fluid technology, applied in the direction of lubricating composition, etc., can solve the problems of high recycling cost, difficult to master the processing process, unstable quality of cutting fluid, etc., and achieve low recycling cost, high practical value, economical and social significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

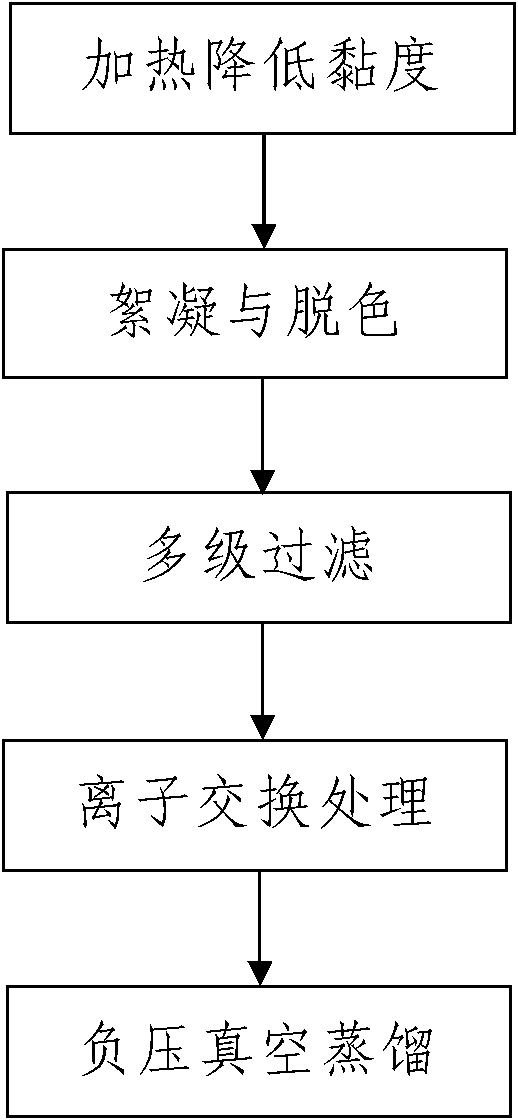

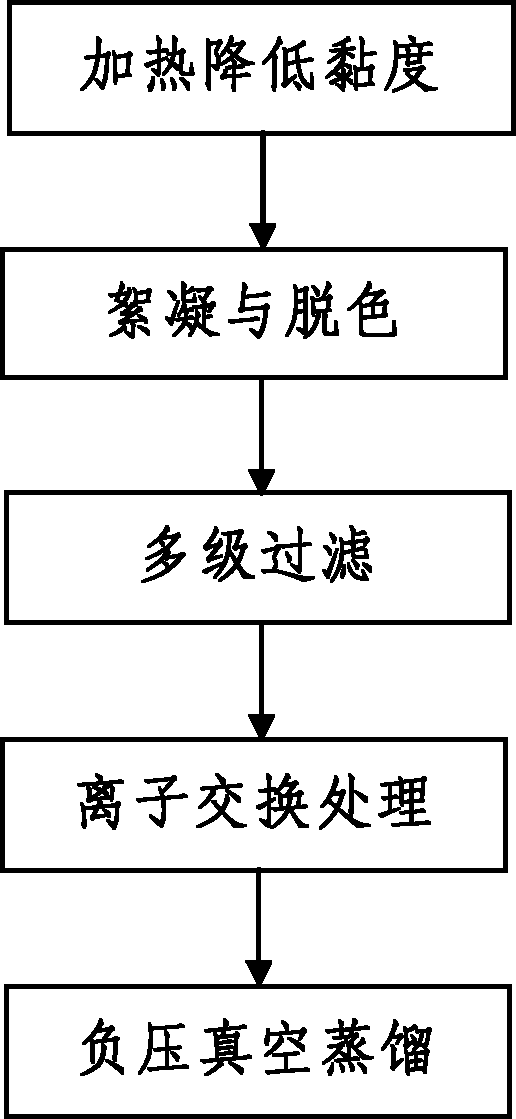

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the recovered 1 ton of colored cutting fluid is heated to 40° C. in the reactor (that is, in the heating device), and fully stirred during the heating process; after that, the heated colored cutting fluid is added with a mass concentration of 10kg of 30% hydrogen peroxide and fully stirred for 10min, so that the hydrogen peroxide oxidatively decomposes the colored substances in the colored cutting fluid, then add 20kg of white clay and fully stirred, and let stand for 30min, so that the oxidized colored material residues are fully adsorbed on the surface of the white clay; Subsequently, the filtrate after the solid-liquid mixture is subjected to the plate and frame pressure filtration of the plate and frame filter press and then successively passes through the filter element to be a melt-blown filter with a pore size of 5 μm, a pleated filter with a pore size of 0.1 μm, and a filter that can reduce the molecular weight. Carry out tertiary filtration f...

Embodiment 2

[0040] In this example, the recovered 2 tons of colored cutting fluid was heated to 60° C. in the reactor (that is, in the heating device), and fully stirred during the heating process; after that, the heated colored cutting fluid was added with a mass concentration of 15kg of 30% hydrogen peroxide and fully stirred for 10min, so that the hydrogen peroxide oxidatively decomposes the colored substances in the colored cutting fluid, then add 40kg of white clay and fully stirred, and let stand for 60min, so that the oxidized colored material residues are fully adsorbed on the surface of the white clay; Subsequently, the filtrate after the solid-liquid mixture is subjected to the plate and frame pressure filtration of the plate and frame filter press and then successively passes through the filter element to be a melt-blown filter with a pore size of 5 μm, a pleated filter with a pore size of 0.1 μm, and a filter that can reduce the molecular weight. Carry out tertiary filtration f...

Embodiment 3

[0042] In this embodiment, the recovered 1 ton of colored cutting fluid is heated to 50° C. in the reactor (that is, in the heating device), and fully stirred during the heating process; after that, the heated colored cutting fluid is added with a mass concentration of 25% hydrogen peroxide 5kg and fully stirred for 15min, so that the hydrogen peroxide oxidatively decomposes the colored substances in the colored cutting fluid, then add 5kg of white clay and fully stirred, and let stand for 70min, so that the oxidized colored material residues are fully adsorbed on the surface of the white clay; Subsequently, the filtrate after the solid-liquid mixture is subjected to the plate and frame pressure filtration of the plate-and-frame filter press and then successively passes through the filter element to be a melt-blown filter element with a pore size of 3 μm, a pleated filter with a pore size of 0.15 μm, and a melt-blown filter with a pore size of 0.15 μm. Carry out tertiary filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com