Novel amorphous silicon cell component

A battery module, amorphous silicon technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of poor adhesion, easy loss of adhesion, loss of protective function, etc., to prevent water vapor infiltration, beneficial to industrial Production and processing, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

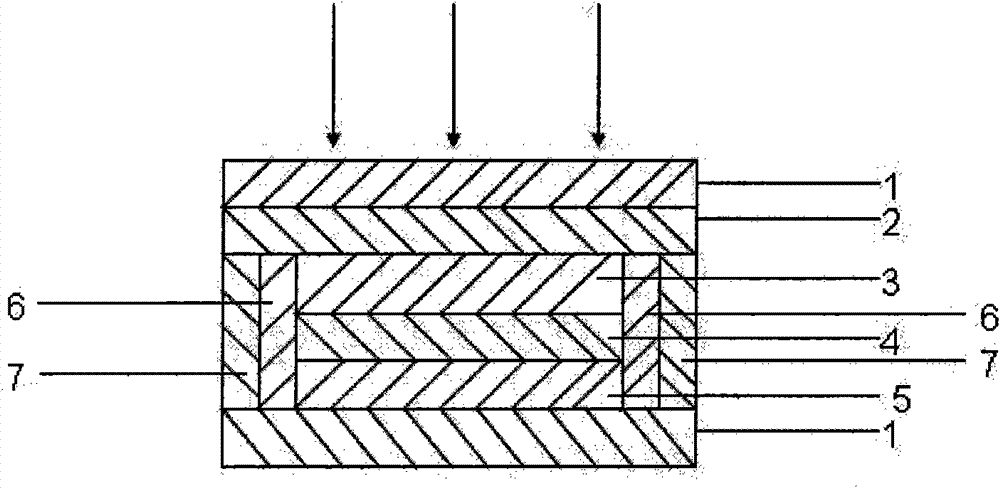

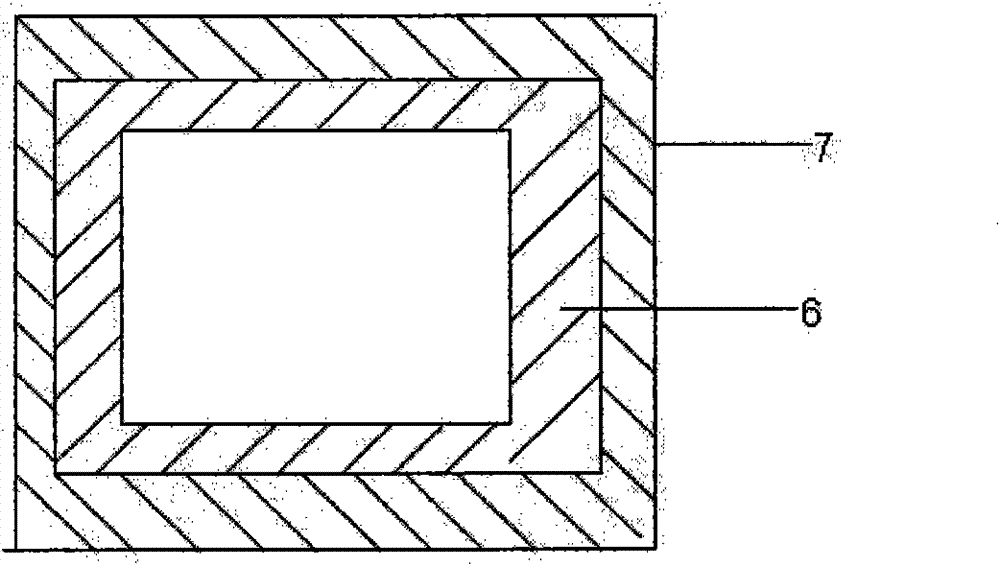

[0021] An amorphous silicon cell assembly, characterized in that the cell assembly is sequentially connected by a glass substrate 1, a transparent electroplating layer 2, an amorphous silicon layer 3, an aluminum film back sheet pole layer 4 and an adhesive layer 5, and the amorphous silicon layer 3 1. The surroundings of the electrode layer 4 of the aluminum film back sheet and the bonding layer 5 are sealed with a sealant layer 1 6 and a sealant layer 2 7 to form an amorphous silicon cell assembly.

[0022] The amorphous silicon layer is an amorphous silicon layer doped with boron atoms and phosphorus atoms.

[0023] The pole layer of the aluminum film back sheet is an aluminum layer or an alloy layer of aluminum and silver.

[0024] The bonding layer is an ethylene vinyl acetate copolymer layer (EVA) or a polyvinyl butyral resin layer (PVB).

[0025] The first six layers of sealant layer are hot-melt adhesives with polyisobutylene and polyisoprene as the main body and inor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com