Method for preparing graphene by chemical oxidation reduction

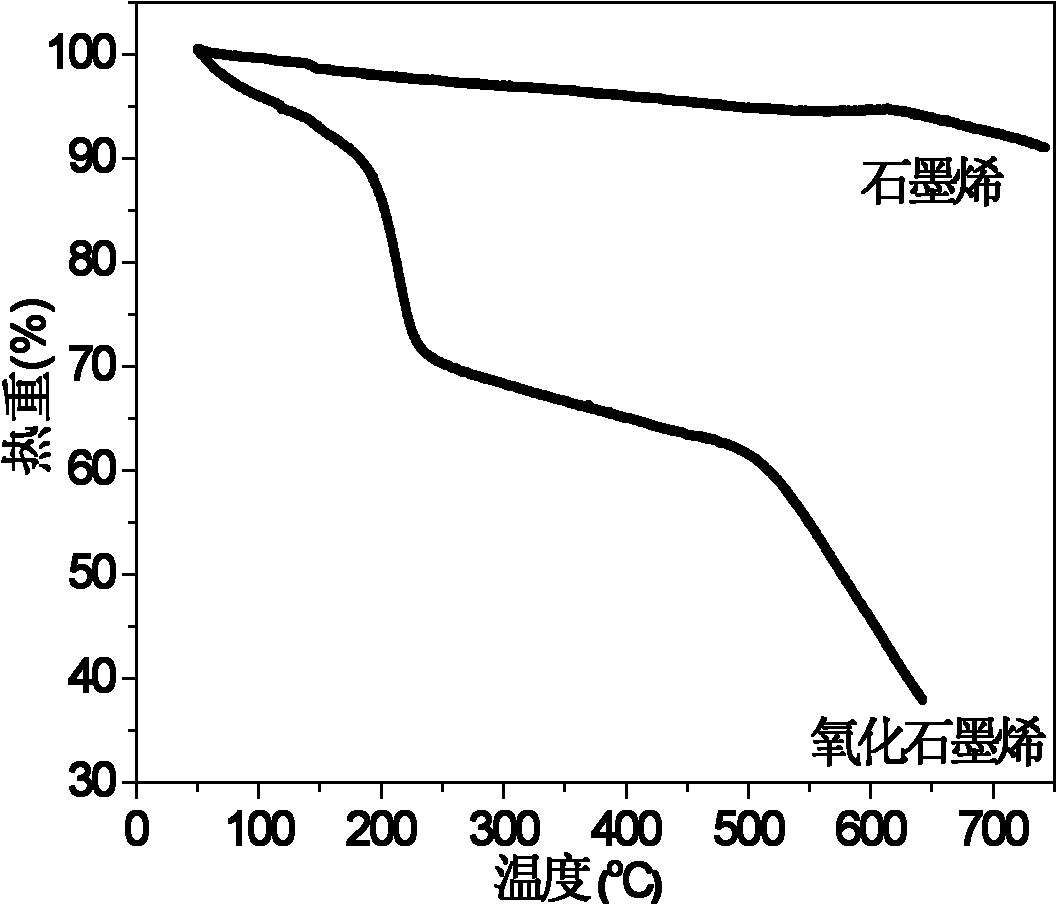

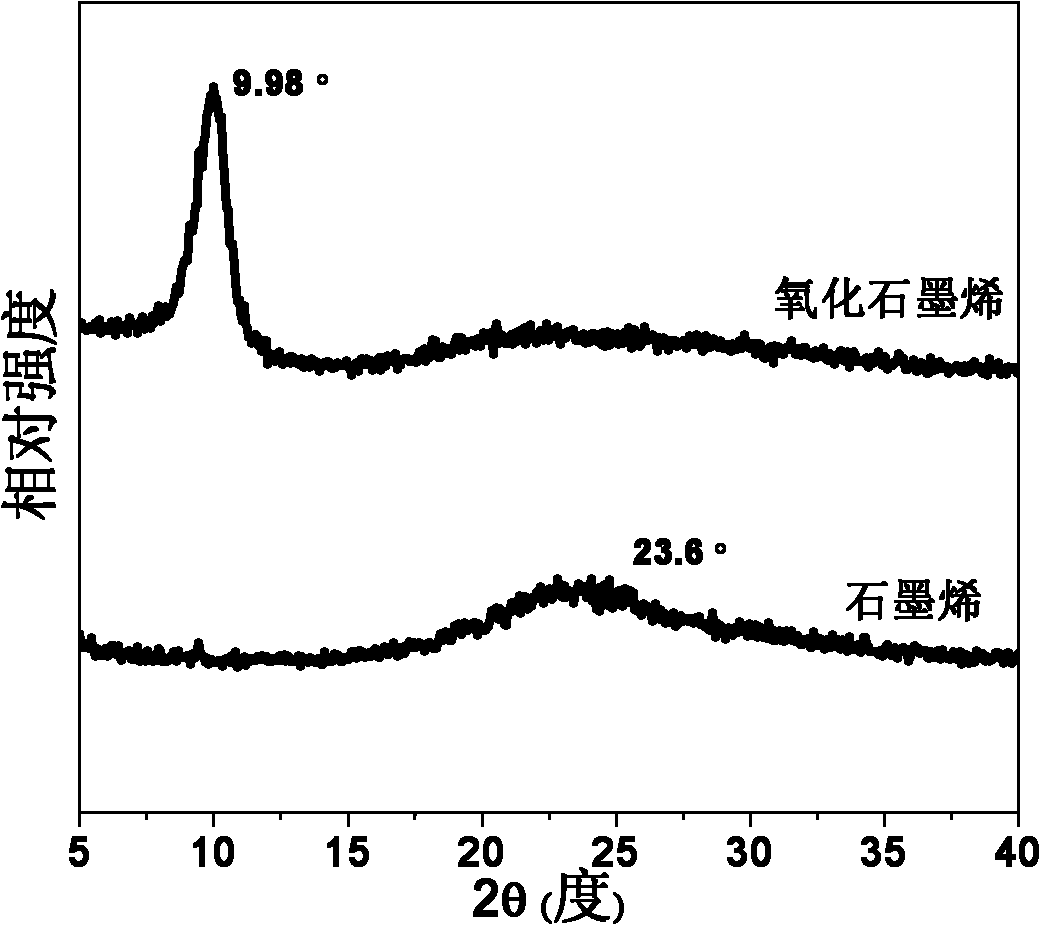

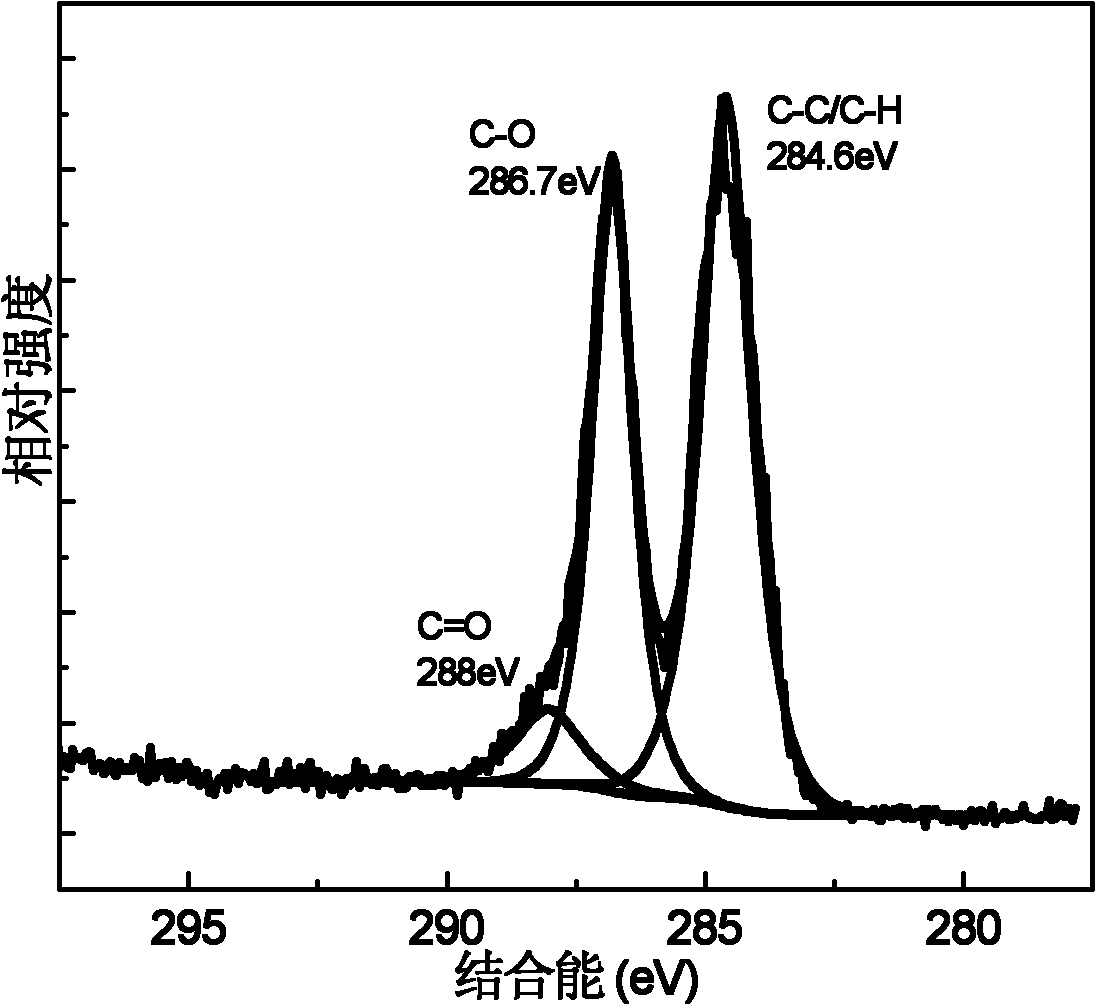

A technology of chemical oxidation and graphene, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low reduction efficiency and long reduction time, and achieve high reduction efficiency, high reduction degree, and good industrial prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First prepare graphite oxide with water solubility by the existing Hummers method, then add graphene oxide into water at a concentration of 1 mg / ml, and ultrasonically oscillate or stir it at room temperature to uniformly disperse it in water to obtain graphite oxide Aqueous solution of graphene oxide (pH=7); first, the obtained aqueous solution of graphene oxide is uniformly coated on the polyester substrate by spin coating, the coating thickness is controlled to be ≤4mm, and the spin coating speed is 100 rpm, and then it is applied on the After vacuum drying at 80°C, a graphene oxide film is formed on the substrate; sodium dithionite and catalyst sodium hydroxide are formulated into a reducing agent aqueous solution at a mass ratio of 1:6, and the concentration of the aqueous solution is 2% by mass of sodium hydroxide ; First, the substrate covered with graphene oxide film is immersed in the reducing agent aqueous solution, and the reduction reaction is carried out at ...

Embodiment 2

[0029]First prepare graphite oxide with water solubility by the existing Hummers method, then add graphene oxide into water at a concentration of 2 mg / ml, and ultrasonically oscillate or stir it at room temperature to uniformly disperse it in water to obtain graphite oxide Aqueous solution of graphene oxide (pH=7); first, the obtained aqueous solution of graphene oxide is evenly coated on the ceramic substrate by spin coating, and the coating thickness is controlled to be less than or equal to 4mm. After vacuum-drying at ℃, a graphene oxide film is formed on the substrate; sodium dithionite and catalyst sodium hydroxide are formulated into an aqueous reducing agent solution in a mass ratio of 1:4, and the concentration of the aqueous solution is 5% in terms of sodium hydroxide mass; First, the substrate covered with graphene oxide film is immersed in an aqueous reducing agent solution, and the reduction reaction is performed at 65°C for 15 minutes, and then the product is washe...

Embodiment 3

[0031] First prepare water-soluble graphene oxide from graphite by the existing Hummers method, then add graphene oxide into water at a concentration of 6 mg / ml, ultrasonically oscillate or stir at room temperature to make it evenly dispersed in water, and add ammonia water Adjust the pH=12 of the graphene oxide aqueous solution; first, the obtained graphene oxide aqueous solution is uniformly coated on the quartz glass substrate by spin coating, and the coating thickness is controlled to be less than or equal to 4mm, and the spin coating speed is 100 revolutions per minute, and then the After it is vacuum-dried at 80° C., a graphene oxide film is formed on the substrate; sodium dithionite and catalyst sodium hydroxide are formulated into an aqueous solution of reducing agent in a mass ratio of 1:2, and the concentration of the aqueous solution is calculated by the mass of sodium hydroxide. 10%; firstly dip the substrate covered with graphene oxide film in an aqueous solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com