High temperature-resisting track-resisting bituminous pavement modified material, preparation method thereof and bituminous product

A technology for asphalt pavement and modified materials, which is applied in the field of new materials in the fields of bridges, roads and tunnels. It can solve the problems of water resistance, stable construction period, short efficiency, complicated SBS asphalt modification, and high pollution, so as to reduce maintenance costs and service life. Long, tough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

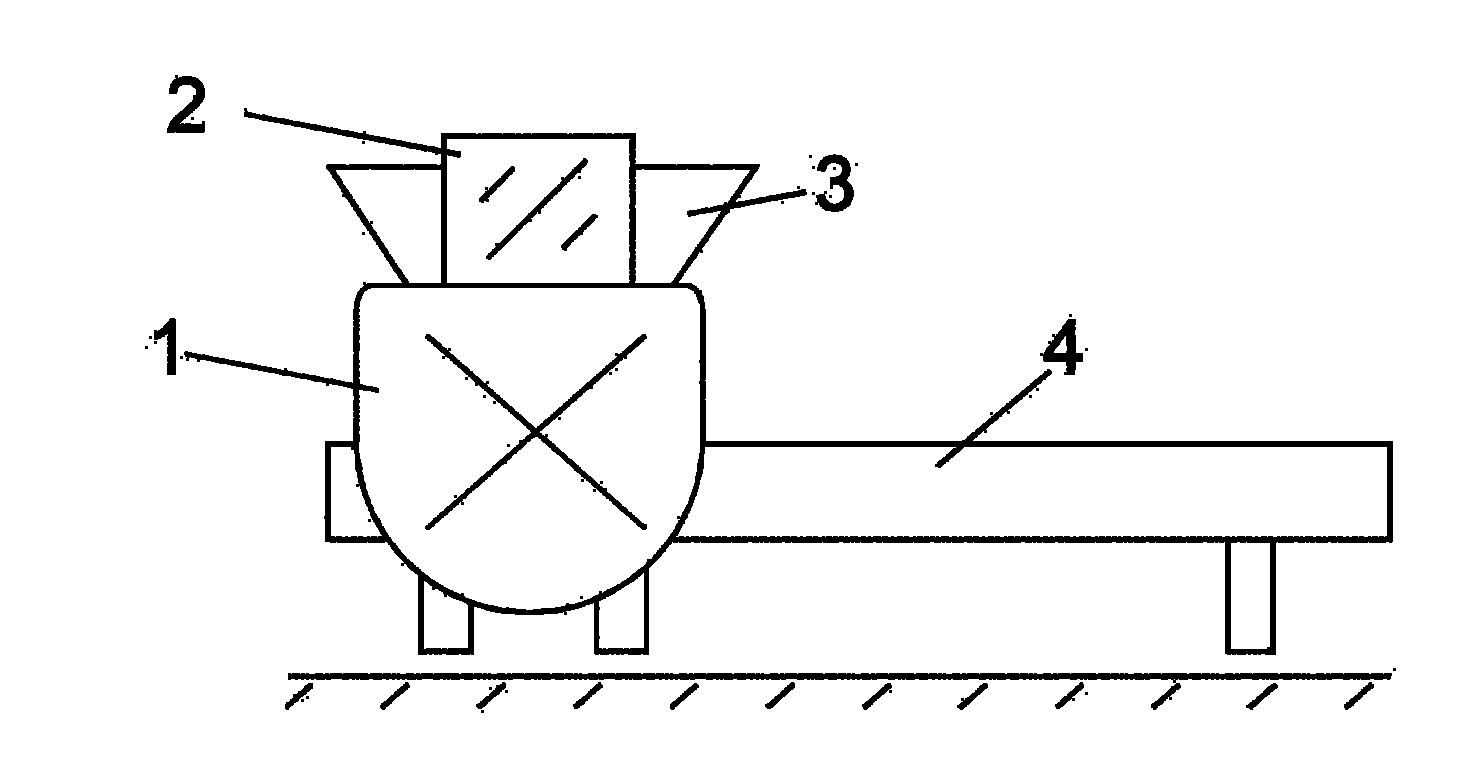

[0073] Please refer to Figure 3a and Figure 3b , the side view and the front view of the preparation equipment of the high-temperature-resistant and anti-rutting asphalt pavement modified material of the present invention, respectively. in Figure 3a The sides of the horizontal mixer 1 , conveyor 2 , single screw machine hopper 3 , single screw machine 4 , twin screw machine hopper 5 and twin screw machine 6 are shown in . and Figure 3b Only the fronts of the horizontal mixer 1 , the conveyor 2 , the single-screw machine hopper 3 and the single-screw machine 4 are shown in . The present invention also specifically provides a preparation method for the above-mentioned high temperature-resistant and rutting-resistant asphalt pavement modified material, including:

[0074] A mixing step, adding NPCC-701 nano-calcium carbonate, SMN resin, diatomaceous earth, LLDPE, cerium oxide nano-stabilizer in the horizontal mixer 1 to mix and stir until a semi-finished asphalt material ...

Embodiment 1

[0094] In one mixing step, add 11 parts of NPCC-701 modified nano-calcium carbonate, 5 parts of SMN resin, 15 parts of diatomaceous earth, 5 parts of LLDPE, and 0.5 part of cerium oxide nano-stabilizer in a horizontal mixer for mixing and stirring until uniform asphalt The materials are semi-finished products; the temperature of primary mixing is room temperature, and the time is 5 minutes.

[0095] In the secondary mixing step, the asphalt material semi-finished product is placed into a single-screw machine through a conveying device, and 10 parts of SMN resin and 8 parts of HDPE are added for mixing and stirring to obtain a mixed extrusion raw material; the temperature of the secondary mixing step is 45 ° C, and the time is for 3 minutes.

[0096] Three mixing steps, introducing the mixed extrusion raw materials into a twin-screw extruder, adding 0.5 parts of JC-GJ301 reinforcing agent, 15 parts of LLDPE and 5 parts of EVA for mixing and stirring, and extruding to obtain the...

Embodiment 2

[0104] In one mixing step, add 20 parts of NPCC-701 modified nano-calcium carbonate, 8 parts of SMN resin, 25 parts of diatomaceous earth, 8 parts of LLDPE, and 0.3 part of cerium oxide nano-stabilizer in a horizontal mixer to mix and stir until uniform asphalt The materials are semi-finished products; the temperature of primary mixing is room temperature, and the time is 5 minutes.

[0105]In the second mixing step, the asphalt material semi-finished product is put into the single screw machine through the conveying device, and 17 parts of SMN resin and 10 parts of HDPE are added for mixing and stirring to obtain the mixed extrusion raw material; the temperature of the second mixing step is 40°C, and the time for 3 minutes.

[0106] Three mixing steps, introducing the mixed extrusion raw materials into a twin-screw extruder, adding 0.8 parts of JC-GJ301 reinforcing agent, 22 parts of LLDPE and 8 parts of EVA for mixing and stirring, and extruding to obtain the high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com