Method for preparing effective part in cumin seed

A technology of effective parts and seeds, which is applied in the field of preparation of effective parts in cumin seeds, and can solve problems such as unclear functional factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] After pulverizing 5.3 kg of cumin seeds, soak and degrease 3 times with petroleum ether at room temperature, each time is 6 hours;

[0018] 5 kg of cumin seeds soaked and degreased are dried in the air, and the concentration is 70% ethanol aqueous solution heat extraction, the temperature is 65 ℃, extracts 3 times, and the time is 4 hours each time, and the extract is collected;

[0019] Merge the extracts, obtain cumin seeds and get extractum 852g after removing the solvent by distillation under reduced pressure;

[0020] Disperse the extracted extract with distilled water, and then sequentially extract 3 times with petroleum ether, dichloromethane and ethyl acetate to obtain 39g of petroleum ether, 20g of dichloromethane, 55.6g of ethyl acetate and 55g of n-butanol ;

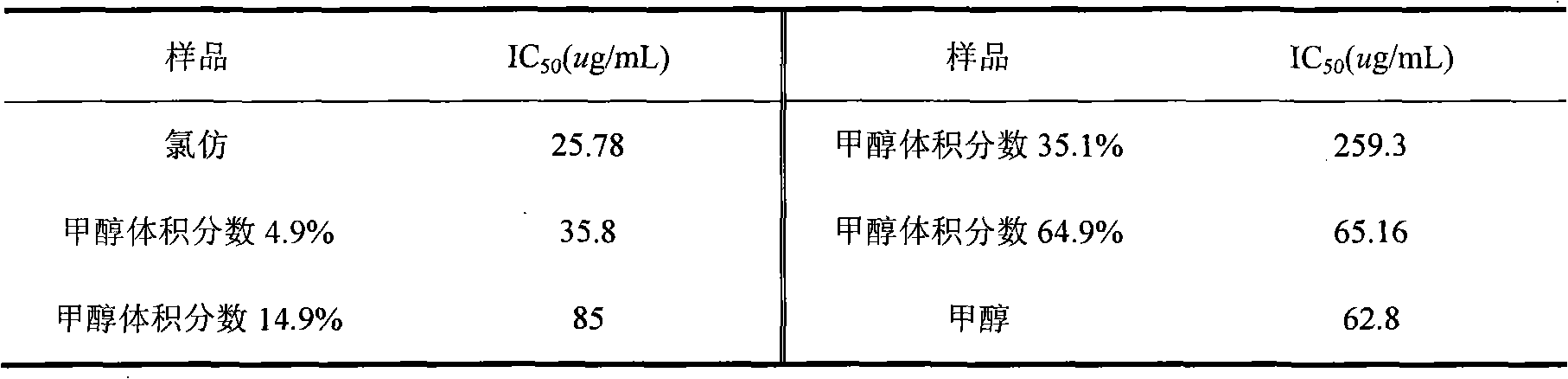

[0021] Dissolve the ethyl acetate part with methanol, mix the sample with silica gel, use rapid preparative chromatography technology, and use chloroform as the eluent to elute (methanol volume fractio...

Embodiment 2

[0023] After pulverizing 5.3 kg of cumin seeds, soak and degrease 3 times with petroleum ether at room temperature, each time is 6 hours;

[0024] 5 kg of cumin seeds soaked and degreased are dried in the air, and the concentration is 70% ethanol aqueous solution heat extraction, the temperature is 65 ℃, extracts 3 times, and the time is 4 hours each time, and the extract is collected;

[0025] Merge the extracts, obtain cumin seeds and get extractum 852g after removing the solvent by distillation under reduced pressure;

[0026] Disperse the extracted extract with distilled water, and then sequentially extract 3 times with petroleum ether, dichloromethane and ethyl acetate to obtain 39g of petroleum ether, 20g of dichloromethane, 55.6g of ethyl acetate and 55g of n-butanol ;

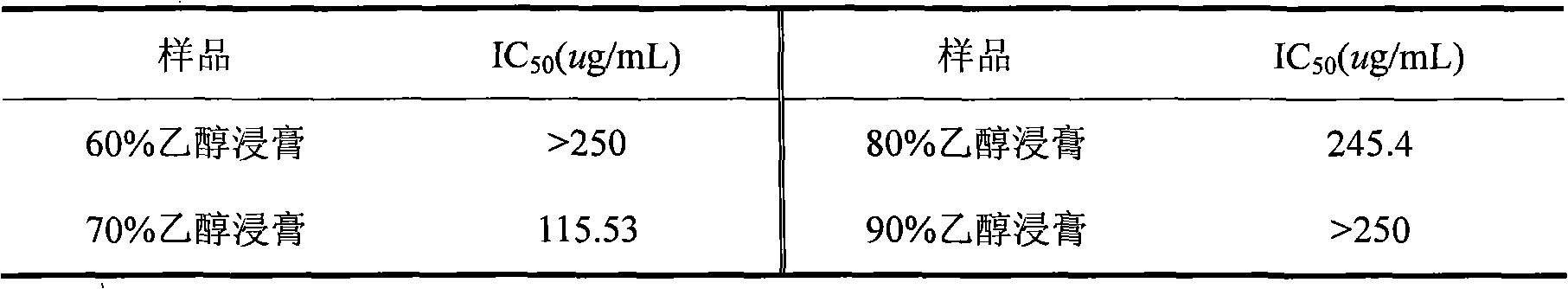

[0027] Dissolve the ethyl acetate part with methanol, mix the sample with silica gel, use the rapid preparative chromatography technique, and use the gradient elution of chloroform and chloroform-metha...

Embodiment 3

[0029] After pulverizing 5.3 kg of cumin seeds, soak and degrease 3 times with petroleum ether at room temperature, each time is 6 hours;

[0030] 5 kg of cumin seeds soaked and degreased are dried in the air, and the concentration is 70% ethanol aqueous solution heat extraction, the temperature is 65 ℃, extracts 3 times, and the time is 4 hours each time, and the extract is collected;

[0031] Merge the extracts, obtain cumin seeds and get extractum 852g after removing the solvent by distillation under reduced pressure;

[0032] Disperse the extracted extract with distilled water, and then sequentially extract 3 times with petroleum ether, dichloromethane and ethyl acetate to obtain 39g of petroleum ether, 20g of dichloromethane, 55.6g of ethyl acetate and 55g of n-butanol ;

[0033] Dissolve the ethyl acetate part with methanol, after mixing the sample with silica gel, use the rapid preparative chromatography technique, the eluent uses chloroform, the chloroform-methanol sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com