Method for synthesizing macronucleus-silica-coated gold core-shell structure nanoparticles

A gold nanoparticle and silicon dioxide technology, which is applied in the synthesis field of large-core silica-coated gold-core-shell structure nanoparticles, can solve problems such as long preparation period, and achieve the effects of good chemical compatibility and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Synthetic gold species

[0027] Add 99ml of water to a 250ml single-mouthed round bottom flask, then add 1.2ml of 24.28mM chloroauric acid solution, heat, and after reflux, add 1ml of 1% sodium citrate solution. Continue heating for 30min to obtain 40nm gold species (see figure 1 ).

[0028] 2) The gold species was further grown to 130nm by the reduction method of hydroxylamine hydrochloride

[0029] Take 4ml of gold species into a single-mouth 250ml round-bottom flask, add 83ml of water, stir, then add 1ml of sodium citrate with a mass fraction of 1%, then add 0.9ml of chloroauric acid solution with a concentration of 24.28mM, stir for 5min, and finally add 1.4 ml of hydroxylamine hydrochloride solution with a concentration of 10 mM, and continue to stir for 30 min. Promptly synthesized the gold particle of 130nm (see figure 2 ).

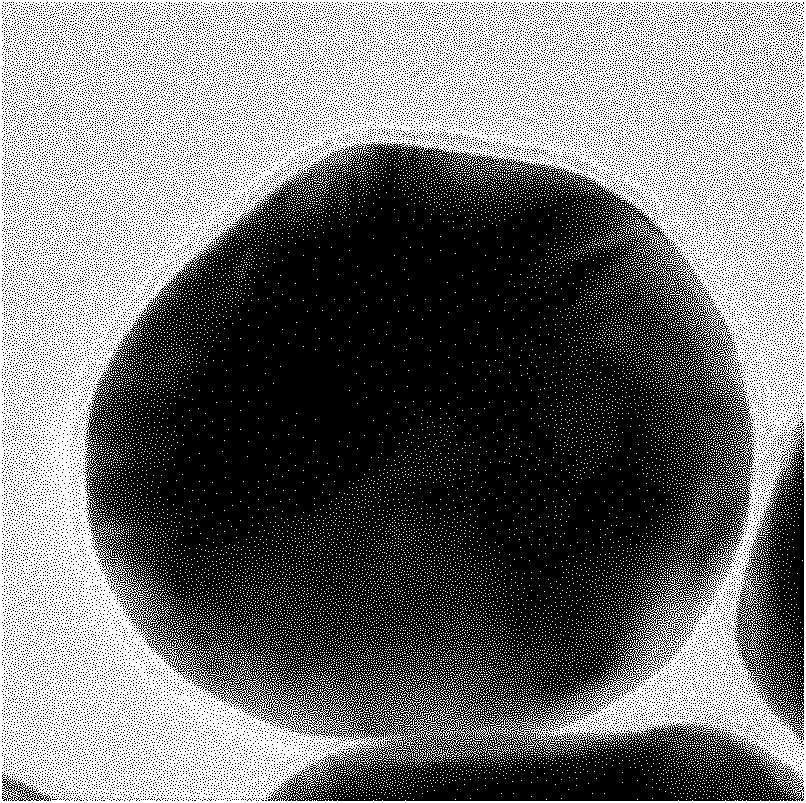

[0030] 3) Synthesis of Au@SiO 2 particle

[0031] Take 2ml of sodium silicate solution with a mass fraction of 27% to a 100ml vo...

Embodiment 2

[0034] 1) Synthetic gold species

[0035] Add 99ml of water into a 250ml single-mouthed round bottom flask, then add 1.2ml of chloroauric acid solution with a concentration of 24.28mM, heat, and after reflux, add 3ml of sodium citrate solution with a mass fraction of 1%, and continue heating for 30min to obtain 16nm gold species.

[0036] 2) The gold species was further grown to 80nm by the reduction method of hydroxylamine hydrochloride

[0037] Take 4ml of gold species into a single-mouth 250ml round bottom flask, then add 190ml of water, stir, then add 3ml of sodium citrate with a mass fraction of 5%, then add 5ml of chloroauric acid solution with a concentration of 24.28mM, stir for 5min, and finally slowly add 1ml of 30mM hydroxylamine hydrochloride solution was stirred for 30min to obtain 80nm gold particles.

[0038] 4) Synthesis of Au@SiO2 particles

[0039] Take 2ml of sodium silicate solution with a mass fraction of 27% to a 100ml volumetric flask, add 60ml of water...

Embodiment 3

[0042] 1) Synthetic gold species

[0043] Add 99ml of water in the 250ml round-bottomed flask of single port, then add the chloroauric acid solution of 1.2ml concentration 24.28mM, heat, after reflux, add the sodium citrate solution of 0.65ml mass volume fraction 1%, continue heating 30min, can obtain 60nm gold species.

[0044] 2) The gold species was further grown to 200nm by the reduction method of hydroxylamine hydrochloride

[0045] Take 4ml of gold species into a single-mouthed 100ml round-bottom flask, add 44ml of water, stir, then add 5ml of sodium citrate with a mass fraction of 1%, then add 1.4ml of chloroauric acid solution with a concentration of 24.28mM, stir for 5min, and finally add 20ml of 1.5mM hydroxylamine hydrochloride solution, continue to stir for 30min, that is to synthesize 200nm gold particles.

[0046] 4) Synthesis of Au@SiO 2 particle

[0047] Take 2ml of sodium silicate solution with a mass fraction of 27% to a 100ml volumetric flask, add 20ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com