Preparation method of phenol polyoxyethylene phosphonate

A technology of phenol polyoxyethylene ether phosphate and polyoxyethylene ether phosphate, which is applied in the field of anionization of nonionic surfactants in organic chemistry, can solve problems such as deep color cannot meet the needs of chemical fiber work applications, and achieve Product stability, strong pertinence, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

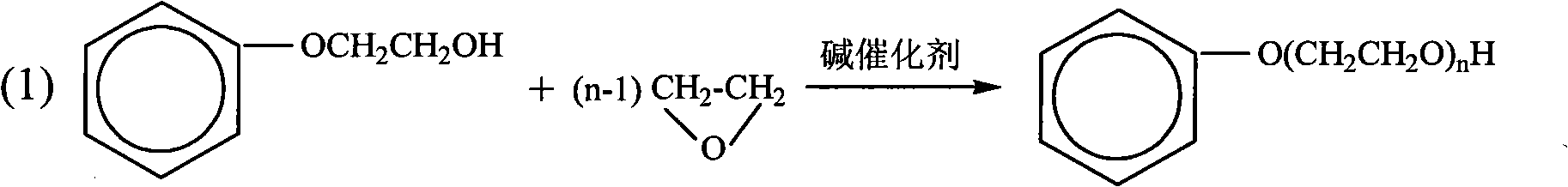

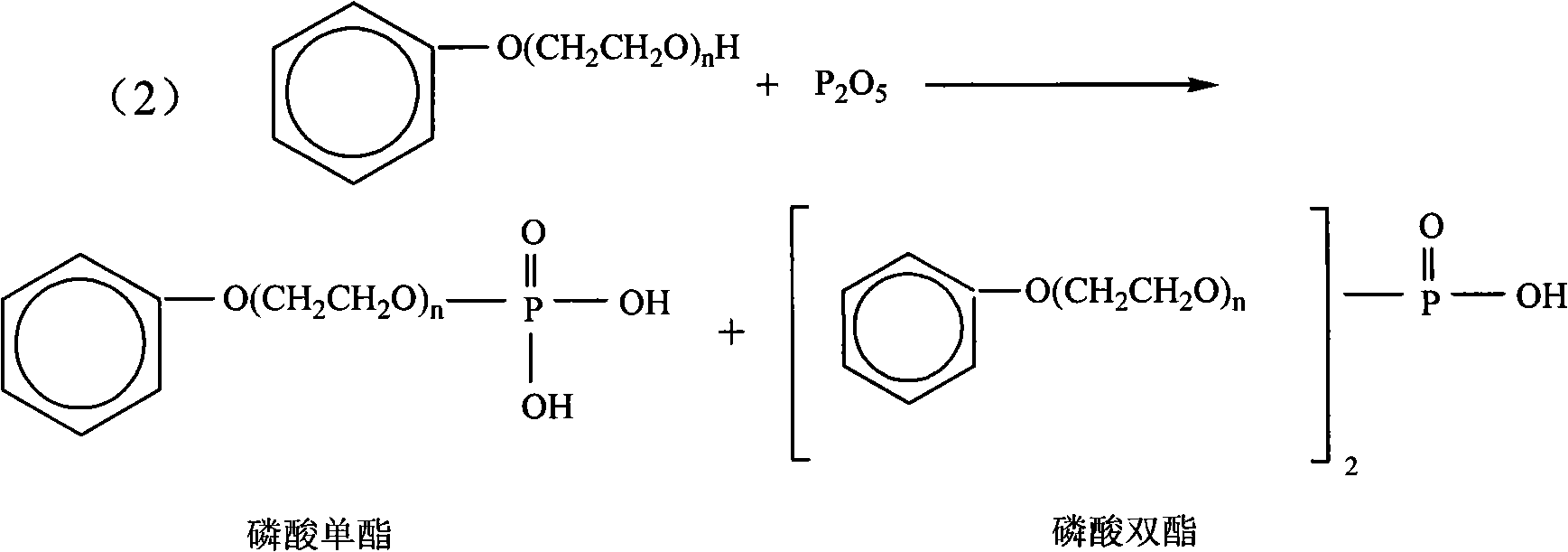

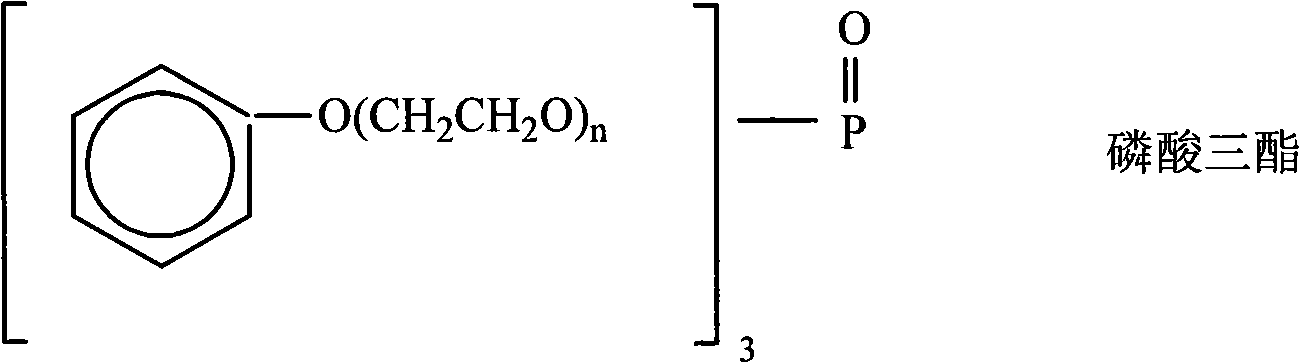

[0021] The preparation method of phenol polyoxyethylene ether phosphate of the present invention, it takes phenoxyethanol as initiator, under the presence of alkali catalyst (KOH, NaOH or sodium methylate any one or more than one mixture) and ring Ethylene oxide is polymerized to obtain phenol polyoxyethylene ether; the phenol polyoxyethylene ether is esterified with phosphorus pentoxide, and the target object of the esterification reaction is added to deionized water for hydrolysis, and the obtained phenol polyoxyethylene ether is Oxyethylene ether phosphate; the molar ratio of phenoxyethanol to ethylene oxide is 1:1-9; the molar ratio of phenol polyoxyethylene ether to phosphorus pentoxide is 2.0-3.5:1.

[0022] The added mass of the base catalyst is 0.1-1.5% of the mass sum of phenoxyethanol and ethylene oxide. The polymerization reaction temperature is 90-150° C., and the reaction time is 2-10 hours; the esterification reaction temperature is 60-90° C., and the reaction ti...

Embodiment 1

[0026] Add 275.0 g of phenoxyethanol and 1.0 g of KOH solid catalyst into a 2.5 L pressure reactor, and connect the ethylene oxide metering tank to the pressure tank. Replace the air with nitrogen for 3 times, wait until the temperature of the reaction kettle rises to 125-130°C, keep the system pressure at 0.2-0.3MPa, start to feed 789.1g of ethylene oxide, complete the passage in 3.0 hours, and continue the reaction for 7 hours. After the reaction was completed, it was cooled and the pressure was released to obtain 1064 grams (about 1.99 mol) of an intermediate whose main component was phenol polyoxyethylene ether phosphate. In the above steps, the molar ratio of phenoxyethanol to ethylene oxide is 1:9.

[0027] Transfer the obtained intermediate to a 1000mL four-neck flask, add 102.9g of phosphorus pentoxide in three batches, react at a temperature of 60-65°C for 10 hours, then add 11.7g of deionized water, and hydrolyze at a temperature of 70-75°C After cooling for 1.5 hou...

Embodiment 2

[0029] Add 150.0 g of phenoxyethanol and 7.3 g of sodium methoxide solid catalyst into a 2.5 L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. Replace the air with nitrogen for 3 times, wait until the temperature of the reaction kettle rises to 90-95°C, keep the system pressure at 0.2-0.3MPa, start to feed 239.1g of ethylene oxide, complete the passage in 2.5 hours, and continue the reaction for 1.5 hours. After the reaction is complete, cool down and release the pressure. 489.1 g (about 1.09 mol) of an intermediate mainly composed of phenol polyoxyethylene ether phosphate was obtained. In the above steps, the molar ratio of phenoxyethanol to ethylene oxide is 1:5.

[0030] Transfer the obtained intermediate to a 1000mL four-neck flask, add 77.2g of phosphorus pentoxide in four batches, react at a temperature of 70-75°C for 4.5 hours, then add 9.3g of deionized water, and hydrolyze at a temperature of 85-90°C After cooling for 2.0 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com