Preparation method of titanium alloy surface sol-gel conversion film

A technology of conversion film and titanium alloy, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems such as the decrease of the stability of the sol system, and achieve good binding force, excellent film-forming performance, extended The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

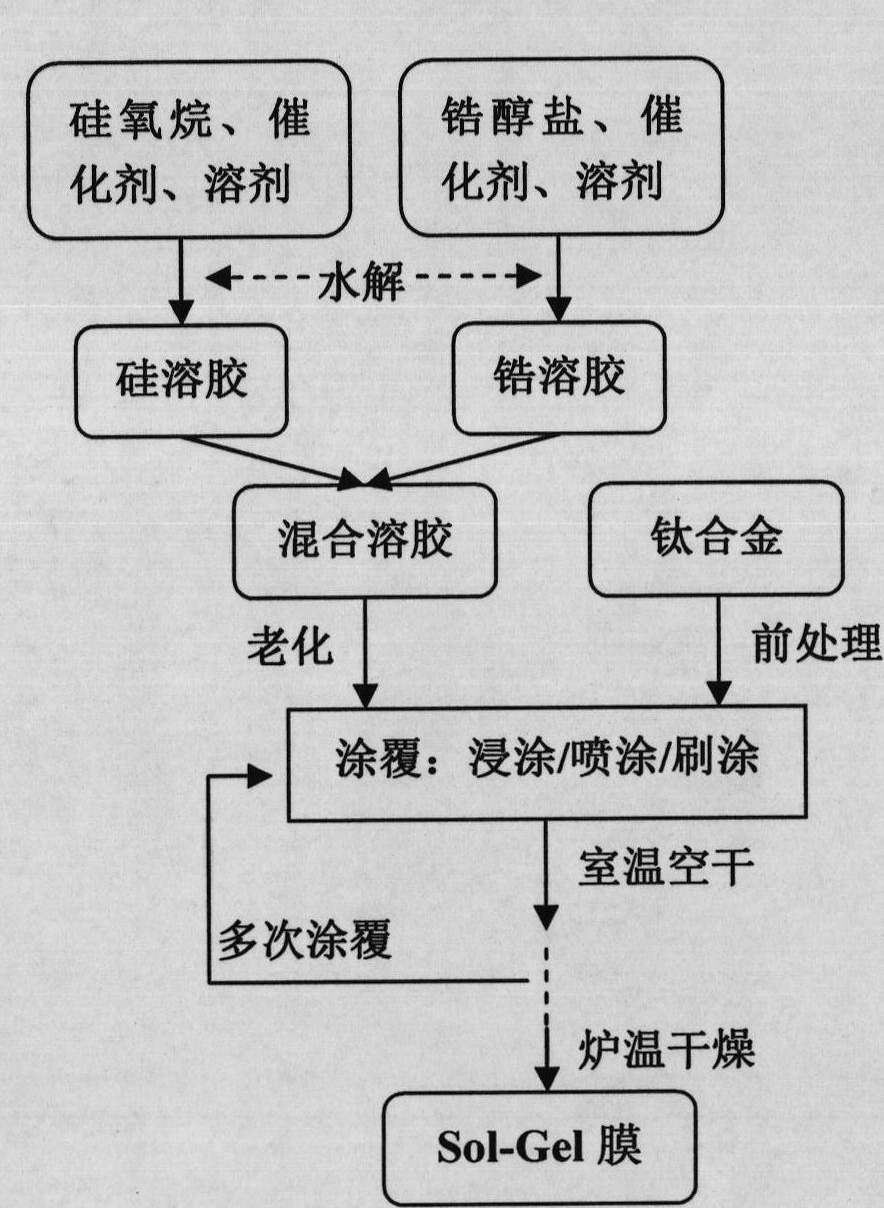

Method used

Image

Examples

Embodiment 1

[0040] 1) Pretreatment of titanium alloy samples

[0041] The pretreatment of titanium alloy samples is carried out according to the regulations in the navigation mark HB / Z 347-2002 "Titanium and Titanium Alloy Anodizing Process" or US Patent 4,614,607.

[0042] 2) Sol preparation

[0043] First, pour 120ml of absolute ethanol and 280ml of deionized water into a 500ml beaker, and stir evenly at room temperature (magnetic stirring speed 500-1000rpm), to obtain the mixed solvent 1. Slowly pour 28ml of γ-glycidyl etheroxypropyltrimethoxysilane into the above mixed solvent 1, and stir in closed state for about 45-60min to obtain organosiloxane sol 2.

[0044] At the same time, pour 7ml of glacial acetic acid and 14ml of zirconium n-propoxide (75%) into a 100ml beaker in turn, and magnetically stir (500-1000rpm) at room temperature for about 30min to obtain a mixture 3 of organometallic alkoxide and organic acid.

[0045] Under vigorous stirring (rotating speed 1200-1600rpm), slo...

Embodiment 2

[0055] 1) Pretreatment of titanium alloy samples

[0056] The pretreatment of titanium alloy samples is carried out according to the regulations in the navigation mark HB / Z 347-2002 "Titanium and Titanium Alloy Anodizing Process" or US Patent 4,614,607.

[0057] 2) Sol preparation

[0058] First, pour 80ml of absolute ethanol and 320ml of deionized water into a 500ml beaker, and stir evenly at room temperature (magnetic stirring speed 500-1000rpm), to obtain the mixed solvent 1. Slowly pour 28ml of γ-glycidyl etheroxypropyltrimethoxysilane into the above mixed solvent 1, and stir in closed state for about 45-60min to obtain organosiloxane sol 2.

[0059] At the same time, pour 7ml of glacial acetic acid and 14ml of zirconium n-propoxide (75%) into a 100ml beaker in turn, and magnetically stir (500-1000rpm) at room temperature for about 30min to obtain a mixture 3 of organometallic alkoxide and organic acid.

[0060] Under vigorous stirring (rotating speed 1200-1600rpm), slow...

Embodiment 3

[0070] 1) Pretreatment of titanium alloy samples

[0071] The pretreatment of titanium alloy samples is carried out according to the regulations in the navigation mark HB / Z 347-2002 "Titanium and Titanium Alloy Anodizing Process" or US Patent 4,614,607.

[0072] 2) Sol preparation

[0073] First, pour 200ml of absolute ethanol and 200ml of deionized water into a 500ml beaker, and stir evenly at room temperature (magnetic stirring speed 500-1000rpm), to obtain the mixed solvent 1. Slowly pour 28ml of γ-glycidyl etheroxypropyltrimethoxysilane into the above mixed solvent 1, and stir in closed state for about 45-60min to obtain organosiloxane sol 2.

[0074] At the same time, pour 7ml of glacial acetic acid and 14ml of zirconium n-propoxide (75%) into a 100ml beaker in turn, and magnetically stir (500-1000rpm) at room temperature for about 30min to obtain a mixture 3 of organometallic alkoxide and organic acid.

[0075] Under vigorous stirring (rotating speed 1200-1600rpm), slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com