Method for producing oil by mixed culture of yeast and alga

A technology of mixed culture and yeast, which is applied in the field of microbial fermentation, can solve few problems, and achieve the effects of high oil yield, simple operation and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

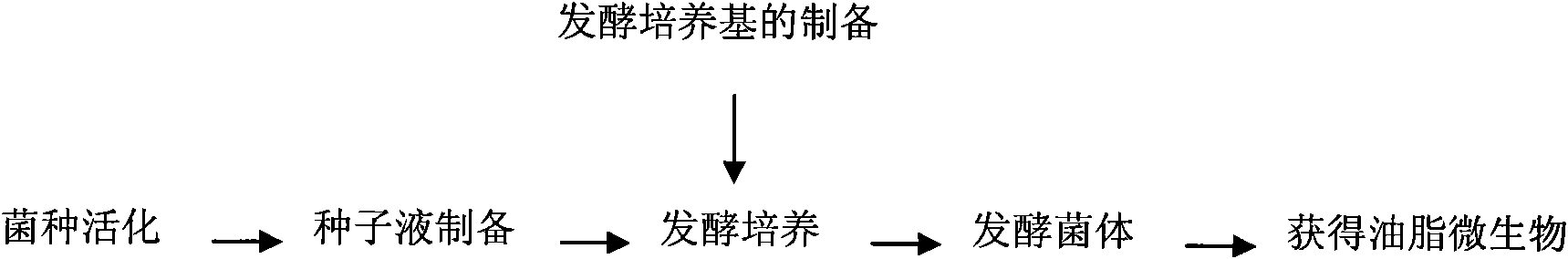

Method used

Image

Examples

Embodiment 1

[0034] The comparison of embodiment 1 Rhodotorula viscosus and Spirulina platensis fermented in mixed culture medium and separate culture to produce oil

[0035] The microorganisms used were Rhodotorula viscosus CGMCC No.2258 (purchased from the China General Microorganism Culture Collection Center) and Spirulina platens FACHB-Collection No.791 (purchased from the Type Culture Collection Committee of the Chinese Academy of Sciences). species library). The formula of seed liquid culture medium is:

[0036] Rhodotorula viscosus: glucose 4g; yeast powder 0.15g; (NH 4 ) 2 SO 4 0.2g; KH 2 PO 4 0.7g; Na 2 SO 4 0.2g; MgSO 4 ·7H 2 O 0.15g, dilute to 100ml with water, adjust pH to 5.5.

[0037] Spirulina platensis: NaHCO 3 16.8g; K 2 HPO 4 0.5g; NaNO 3 2.5g; NaCl 1.0g; MgSO 4 ·7H 2 O 0.2g; K 2 SO 4 1.0g; FeSO 4 ·7H 2 O 10mg; EDTA 80mg; CaCl 2 4 mg; H 3 BO 3 2.86mg; (NH 4 ) 6 Mo 7 o 24 0.02mg; MnCl 2 4H 2 O 1.8 mg; CuSO 4 ·5H 2 O 0.125 mg; ZnSO 4 ·7H 2 O...

Embodiment 2

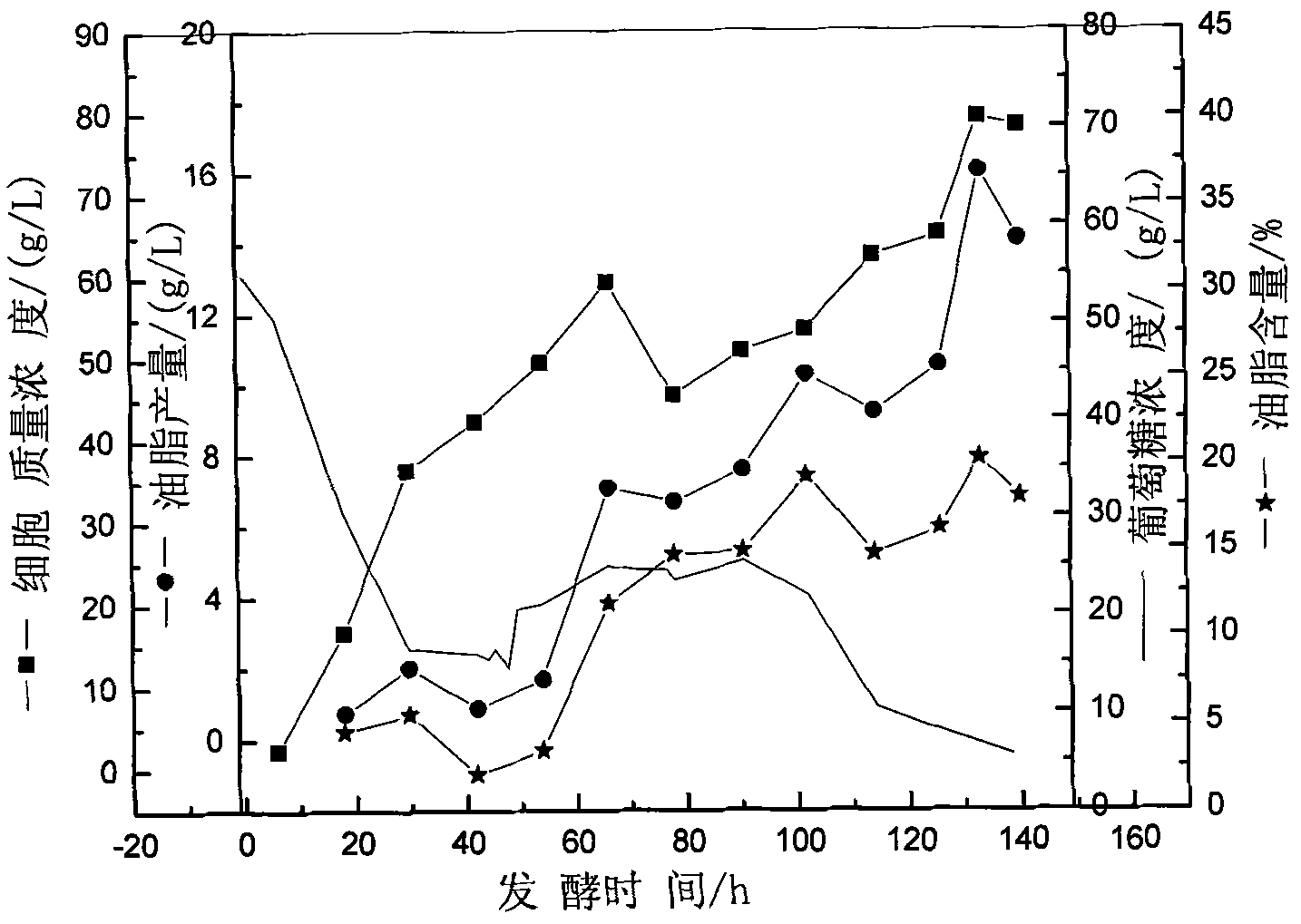

[0051] Example 2 Mixed cultivation of Rhodosporidium toruloides and Spirulina platensis in a stirred tank to produce microbial oil by batch fermentation

[0052] The microorganism used is Rhodosporidium toruloides (Rhodosporidium toruloides) CGMCC No.2.1609, purchased from China General Microorganism Culture Collection and Management Center, Spirulina platensis (same example 1). The formula of seed liquid culture medium is:

[0053] Rhodosporidium toruloides: glucose 20g; yeast powder 1.5g; (NH 4 ) 2 SO 4 0.1g; KH2 PO 4 0.4g; MgSO 4 ·7H 2 O1.5g, dilute to 1L with water, adjust pH to 6.0.

[0054] Spirulina platensis: NaHCO 3 16.8g; K 2 HPO 4 0.5g; NaNO 3 2.5g; NaCl 1.0g; MgSO 4 ·7H 2 O 0.2g; K 2 SO 4 1.0g; FeSO 4 ·7H 2 O 10mg; EDTA 80mg; CaCl 2 4 mg; H 3 BO 3 2.86mg; (NH 4 ) 6 Mo 7 o 24 0.02mg; MnCl 2 4H 2 O 1.8 mg; CuSO 4 ·5H 2 O 0.125 mg; ZnSO 4 ·7H 2 O 0.22mg, dilute to 1L with water.

[0055] The mixed medium is an optimized medium, the formul...

Embodiment 3

[0063] Example 3 Mixed cultivation of rhodotorula viscosus and chlorella fed-batch fermentation to produce microbial oil in a stirred tank

[0064] The microorganisms used were Rhodotorula viscosus (same example 1) and Chlorella vulgaris FACHB-Collection No.791 (Chlorella vulgaris was purchased from the Freshwater Algae Species Bank of the Type Culture Collection Committee of the Chinese Academy of Sciences).

[0065] The formula of seed liquid culture medium is:

[0066] Rhodotorula viscosus: glucose 4g; yeast powder 0.15g; (NH 4 ) 2 SO 4 0.2g; KH 2 PO 4 0.7g; Na 2 SO 4 0.2g; MgSO 4 ·7H 2 O 0.15g, dilute to 100ml with water, adjust pH to 5.5.

[0067] Chlorella: NaNO 3 1.5g; K 2 HPO 4 ·3H 2 O 0.04g; MgSO 4 ·7H 2 O 0.075g; CaCl 2 2H 2 O 0.036g; Citric acid 0.006g; Ferric ammonium citrate 0.006g; EDTA 0.001g; 2 CO 3 0.02g; A 5 1mL; add water to make up to 1L. A 5 Recipe: H 3 BO 3 2.86g; MnCl 2 ·H 2 O 1.81g; ZnSO 4 ·7H 2 O 0.222g; CuSO 4 ·5H 2 O 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com