Process for preparing bronze Nb3Sn superconducting wire material

A technology of superconducting wire rod and preparation process, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. problems such as current carrying, to achieve the effect of improving the performance of the strand, shortening the heat treatment cycle, and optimizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

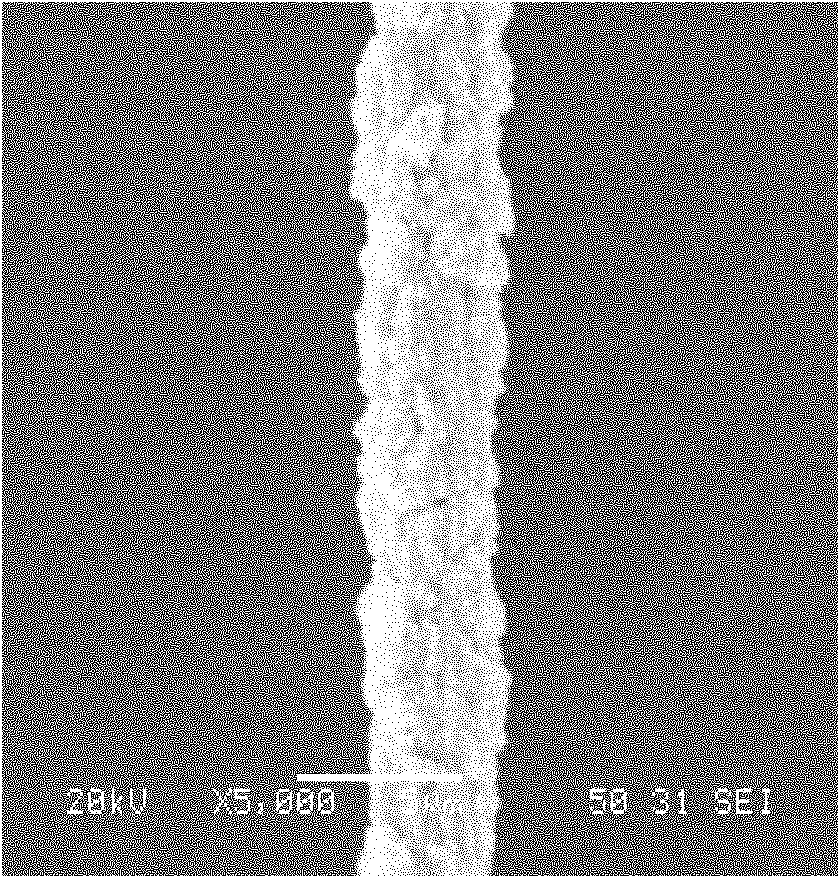

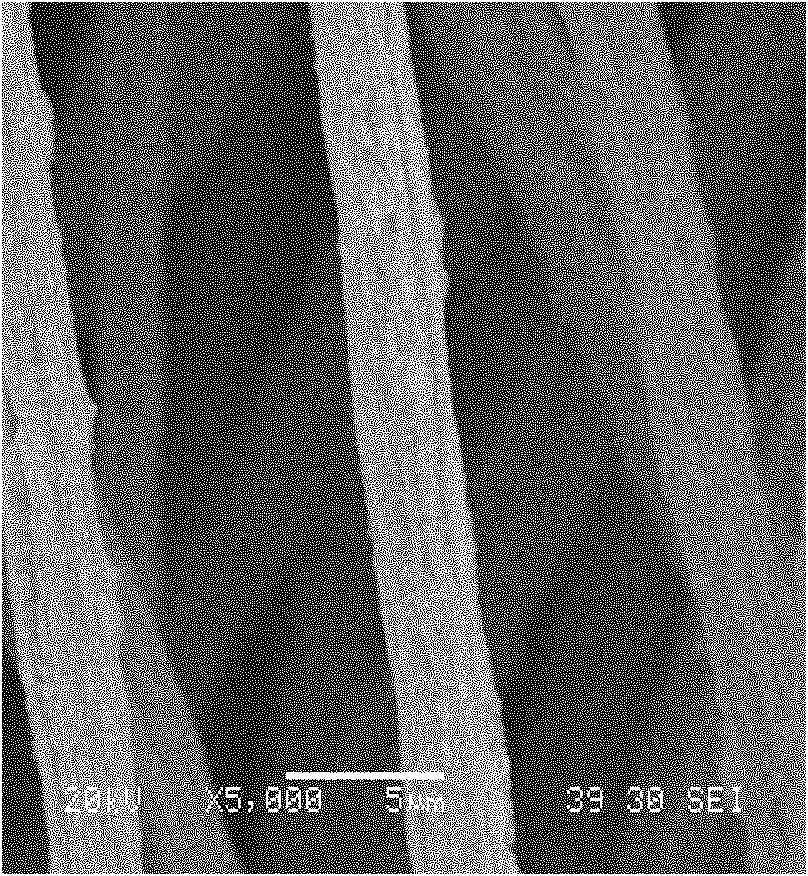

Image

Examples

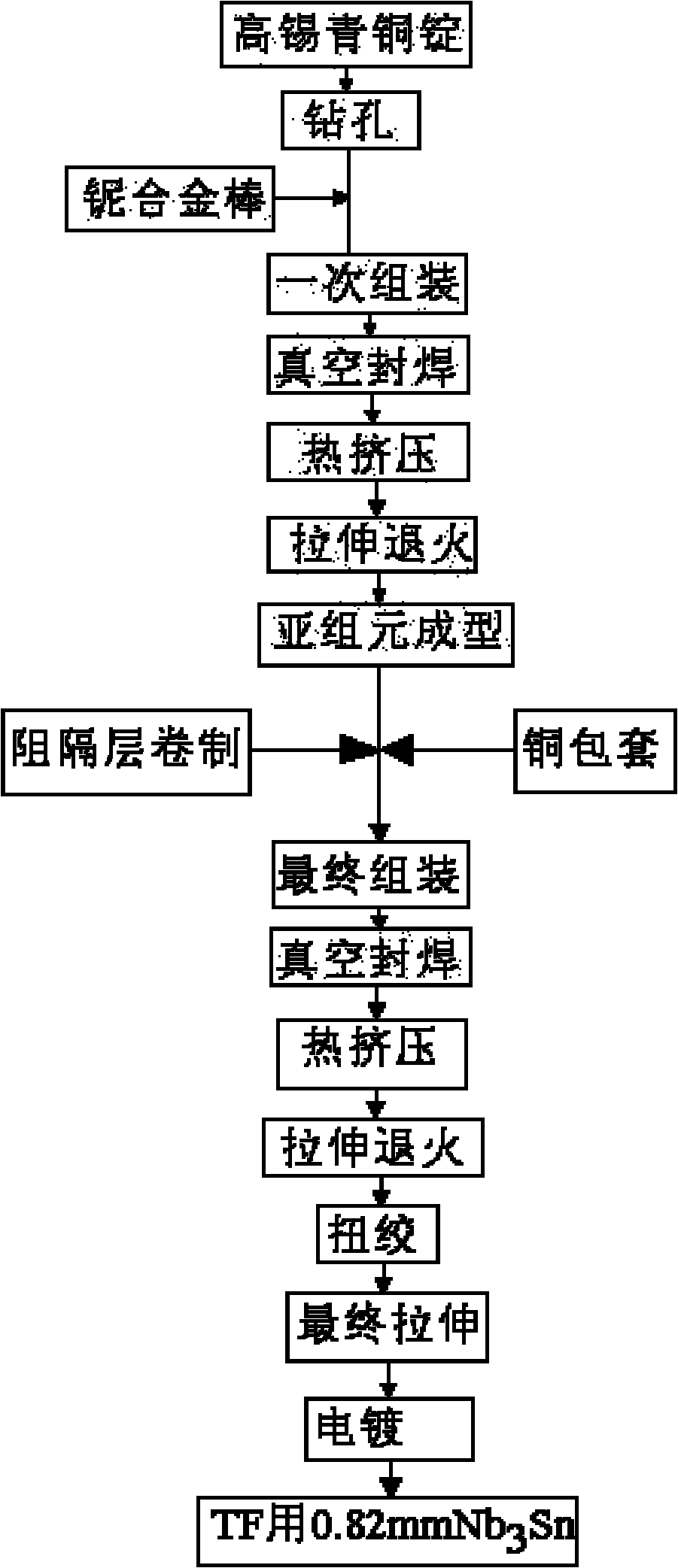

Embodiment 1

[0026] The high-tin bronze ingot is drilled and assembled with a niobium alloy rod, and then EB electron beam vacuum sealing and welding is used to obtain a billet to be extruded with a diameter of Φ200mm, and then a billet a with a diameter of Φ60mm is obtained through hot extrusion, and the billet a is used as a drawing The blank is loaded into the annealing furnace for the first annealing, and after being loaded into the annealing furnace, it is vacuumed to less than 1.0×10 -2 Pa, the furnace chamber is filled with high-purity argon, and the vacuum degree is 8.5×10 3 Pa, heat up to 420°C with a heating rate of 4°C / min; use a thermocouple to monitor the material temperature, and keep the temperature for 30 minutes after the material temperature reaches 420°C; The material is stretched repeatedly at a processing rate of 10%, and then the hexagonal subcomponent is obtained through the subcomponent forming process. The obtained hexagonal subcomponent, barrier layer, and copper ...

Embodiment 2

[0029] The high-tin bronze ingot is drilled and assembled with a niobium alloy rod, and then EB electron beam vacuum sealing welding is used to obtain a billet to be extruded with a diameter of Φ100mm, and then a billet a with a diameter of Φ30mm is obtained through hot extrusion, and the billet a is used as a drawing The blank is loaded into the annealing furnace for the first annealing, and after being loaded into the annealing furnace, it is vacuumed to 8.5×10 -3Pa, the furnace chamber is filled with high-purity nitrogen, and the vacuum degree is 5.3×10 3 Pa, heat up to 480°C at a rate of 5°C / min; use a thermocouple to monitor the material temperature, and keep the temperature for 60 minutes after the material temperature reaches 480°C; The processing rate repeatedly stretches the material, and then obtains the hexagonal subcomponent through the subcomponent forming process. The obtained hexagonal subcomponent, the barrier layer, and the copper sheath are finally assembled,...

Embodiment 3

[0032] The high-tin bronze ingot is drilled and assembled with a niobium alloy rod, and then EB electron beam vacuum sealing and welding is used to obtain a billet to be extruded with a diameter of Φ170mm, and then a billet a with a diameter of Φ55mm is obtained through hot extrusion, and the billet a is used as a drawing The billet is loaded into the annealing furnace for the first annealing, and after being loaded into the annealing furnace, it is vacuumed to 6.5×10 -3 Pa, the furnace chamber is filled with high-purity argon, and the vacuum degree is 1.01×10 5 Pa, heat up to 430°C at a speed of 8°C / min; use a thermocouple to monitor the material temperature, and keep the temperature for 90 minutes after the material temperature reaches 430°C; The % processing rate is used to repeatedly stretch the material; then the hexagonal subcomponent is obtained through the subcomponent forming process, and the obtained hexagonal subcomponent, barrier layer, and copper sheath are finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com