Method for manufacturing microbiological fuel cell (MFC) based on composite nano-interface

A fuel cell and microbial technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve problems such as low power generation efficiency, improve power generation performance, increase speed and quantity, and solve environmental pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of a microbial fuel cell (MFC) anode based on a composite nanointerface

[0026] Dissolve 1mg of carbon nanotube / gold / titanium dioxide composite nanoparticles (P25) in 2ml of 1-methyl-2-pyrrolidone and disperse ultrasonically for 20min to obtain a black carbon nanotube / gold / titanium dioxide composite nanosol (mass concentration: 0.5mg / ml). Wash the cleaned glassy carbon electrode, ITO electrode, carbon paper or carbon cloth and other electrodes in acetone, absolute ethanol, and ultrapure water respectively, and blow dry. Take 4-10mL carbon nanotube / gold / titanium dioxide composite nanosol with a micro-sampler and evenly drop-coat it on the conductive surface of the relevant electrode, and place it in a desiccator to dry to obtain the modified electrode. Wherein, the volume of the carbon nanotube / gold / titanium dioxide composite nanosol to be measured may be any value in the range of 4-10 mL.

[0027]

Embodiment 2

[0028] Example 2 Preparation of a microbial fuel cell (MFC) anode based on a composite nanointerface

[0029] Dissolve 1mg of carbon nanotube / gold / titanium dioxide composite nanoparticles (P25) in 2ml of 1-methyl-2-pyrrolidone and disperse ultrasonically for 20min to obtain a black carbon nanotube / gold / titanium dioxide composite nanosol (mass concentration: 0.5mg / ml). Wash the cleaned glassy carbon electrode, ITO electrode, carbon paper or carbon cloth and other electrodes in acetone, absolute ethanol, and ultrapure water respectively, and blow dry. Take 8mL of carbon nanotube / gold / titanium dioxide composite nanosol with a micro-sampler and evenly drop-coat it on the conductive surface of the relevant electrode, and place it in a desiccator to dry to obtain the anode electrode modified by the nano-self-assembly system.

[0030]

Embodiment 3

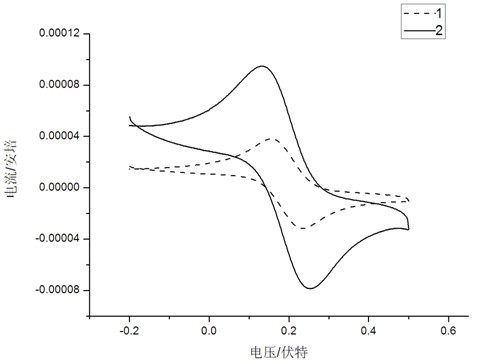

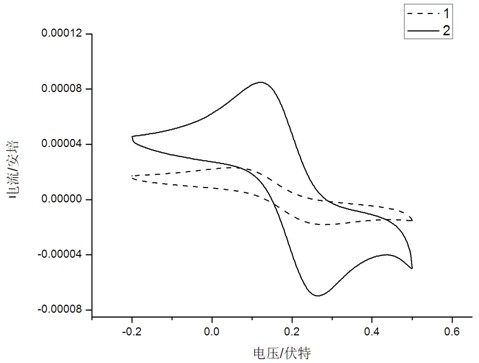

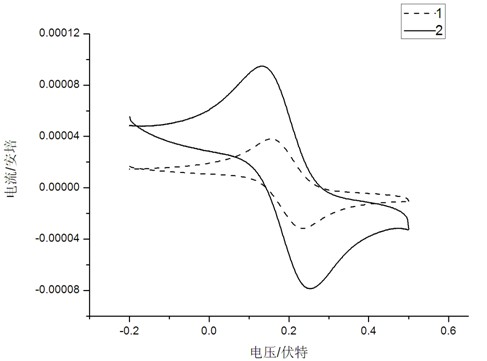

[0031] Example 3 Electrochemical response of electrochemical probes on composite nanointerfaces

[0032]Using a three-electrode system, silver wire is used as a reference electrode, platinum wire is used as an auxiliary electrode, and the electrodes before and after modifying carbon nanotubes / gold / titanium dioxide nanoparticles are respectively used as working electrodes to study electrochemical methods such as potassium ferricyanide. Electrochemical properties of the probes at these two interfaces. It was found that the composite nanointerface can significantly accelerate the electron transfer rate compared with the bare electrode conductive interface. E.g, figure 1 is the cyclic voltammogram of potassium ferricyanide, in which red is the bare glassy carbon electrode, blue is the modified electrode, from figure 1 It can be seen that the peak current of potassium ferricyanide on the composite nanointerface is significantly enhanced compared with the bare electrode, indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com