Anti-aging cosmetic

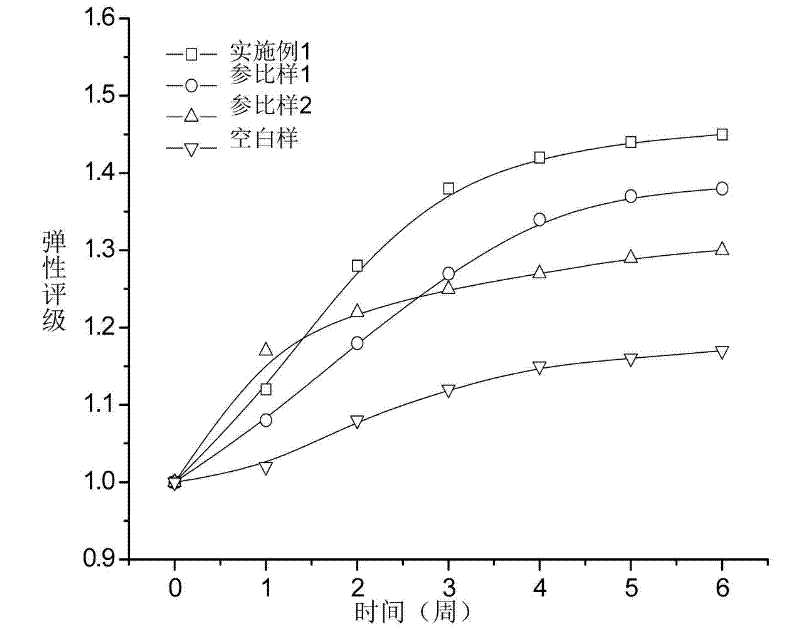

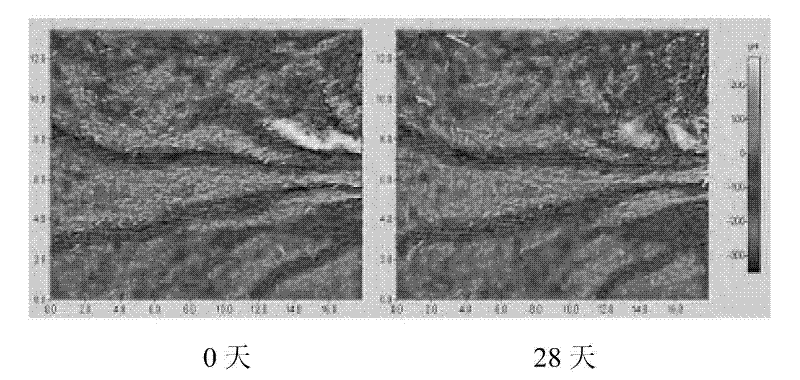

A cosmetic and anti-aging technology, which is applied in the field of cosmetics with anti-aging effect, can solve the problems of poor anti-aging effect, and achieve the effect of good anti-aging effect, excellent cold and heat stability, and convenient promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned anti-aging cosmetics comprises the following steps:

[0038] 1) Heat the solid oil, liquid oil, and emulsifier to 70°C-90°C, stir until the raw materials are completely dissolved to obtain the oil phase;

[0039] 2) Heat the humectant and deionized water to 80°C-95°C, stir until the raw materials are completely dissolved to obtain the water phase;

[0040] 3) Mix the oil phase and the water phase evenly, stir and emulsify to obtain an emulsion;

[0041] 4) Add Luremin to the emulsion TM , BIOTIGHTENER, and stir evenly to obtain the product.

[0042] Adjust the pH of the emulsion to 5-8, preferably, adjust the pH to 6.5-7.5.

[0043] Of course, if the pH of the obtained emulsion is 5-8, preferably 6.5-7.5, there is no need to adjust the pH of the emulsion.

[0044] When adjusting the pH of the emulsion, it is preferable to adjust the pH of the emulsion using triethanolamine.

Embodiment 1

[0052] 1) 0.5% of shea butter, 1% of phytosterol, 4% of liquid oil isomerized hexadecane, 3% of hydrogenated polydecene, 3% of isooctyl palmitate, 0.5% of vitamin E acetate, cetearyl 2.5% fatty acid alcohol and cocoyl glucoside, 2.5% glycerol stearate (and) PEG-100 stearate, heated to 70°C-90°C, stirred until the raw materials are completely dissolved, and the oil phase is obtained;

[0053] 2) Heat 0.25% carbomer Tr-1, 10% glycerin, 8% propylene glycol, 4% betaine, and 58.33% deionized water to 80°C-95°C, stir until the raw materials are completely dissolved to obtain the water phase;

[0054] 3) Mix the oil phase and the water phase evenly, stir and emulsify to obtain an emulsion;

[0055] 4) Slowly cool the emulsified system to below 50°C, use triethanolamine to adjust the pH of the emulsified liquid to 7.0, add Luremin to the emulsified liquid TM1%, BIOTIGHTENER 1%, preservative bis(hydroxymethyl) imidazolidinyl urea 0.3%, methylisothiazolinone 0.1%, essence 0.02%, stir e...

Embodiment 2

[0057] 1) 0.5% shea butter, 0.5% phytosterol, 4% cetane, 3% polydimethylsiloxane, 2% isooctyl palmitate, 2% hydrogenated polydecene, vitamin E Acetate 0.5%, hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer 1.5%, heat to 70°C-90°C, stir until the raw materials are completely dissolved to obtain an oil phase;

[0058] 2) Heat 8% glycerin, 8% propylene glycol, 4% betaine, and 62.58% deionized water to 80°C-95°C, and stir until the raw materials are completely dissolved to obtain the water phase;

[0059] 3) Mix the oil phase and the water phase evenly, stir and emulsify to obtain an emulsion;

[0060] 4) Cool the emulsified system above slowly to below 50°C, add Luremin to the emulsified liquid TM 1.5%, BIOTIGHTENER 1.5%, preservative bis(hydroxymethyl) imidazolidinyl urea 0.3%, methylisothiazolinone 0.1%, essence 0.02%, stir evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com