Carbon-nano-tube prepared from poplar catkin and willow catkin as raw materials and preparation method

A technology of carbon microtubes and catkins, which is applied in the field of preparation of carbon microtubes, can solve problems such as failure to find, and achieve good catalytic oxygen reduction reaction performance and capacitance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

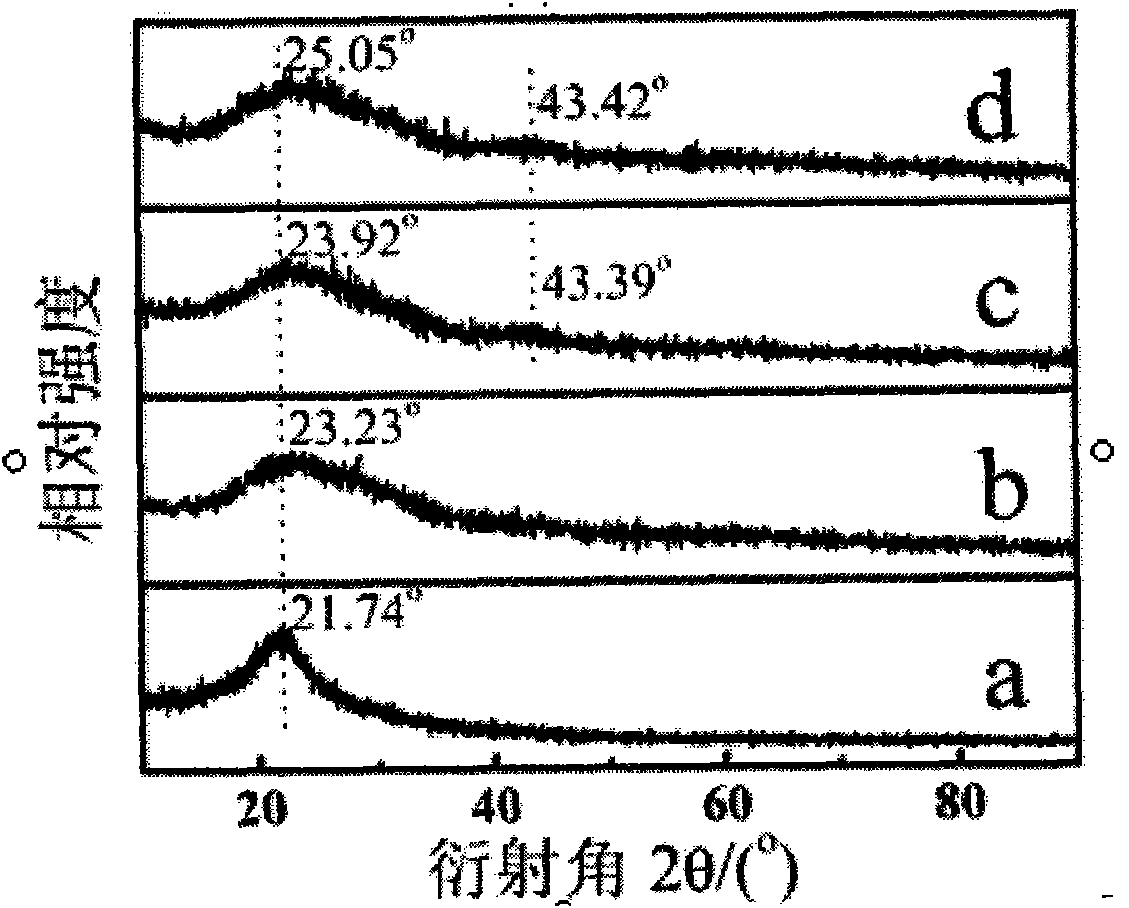

[0023] Example 1 Put 100 mg of catkins in the middle area of the quartz tube in a horizontal tube furnace, heat it to a reaction temperature of 250-2000 °C at a heating rate of 1-30 °C / min under an argon protective atmosphere, and carbonize it for 10-180 min The product was obtained by naturally cooling to room temperature under an argon protective atmosphere.

Embodiment 2

[0024] Example 2 Put 100 mg catkins in the middle area of the quartz tube in a horizontal tube furnace, heat it to a reaction temperature of 250-2000 °C at a heating rate of 1-30 °C / min under an argon protective atmosphere, and carbonize it for 1-180 min The product was obtained by naturally cooling to room temperature under an argon protective atmosphere.

Embodiment 3750

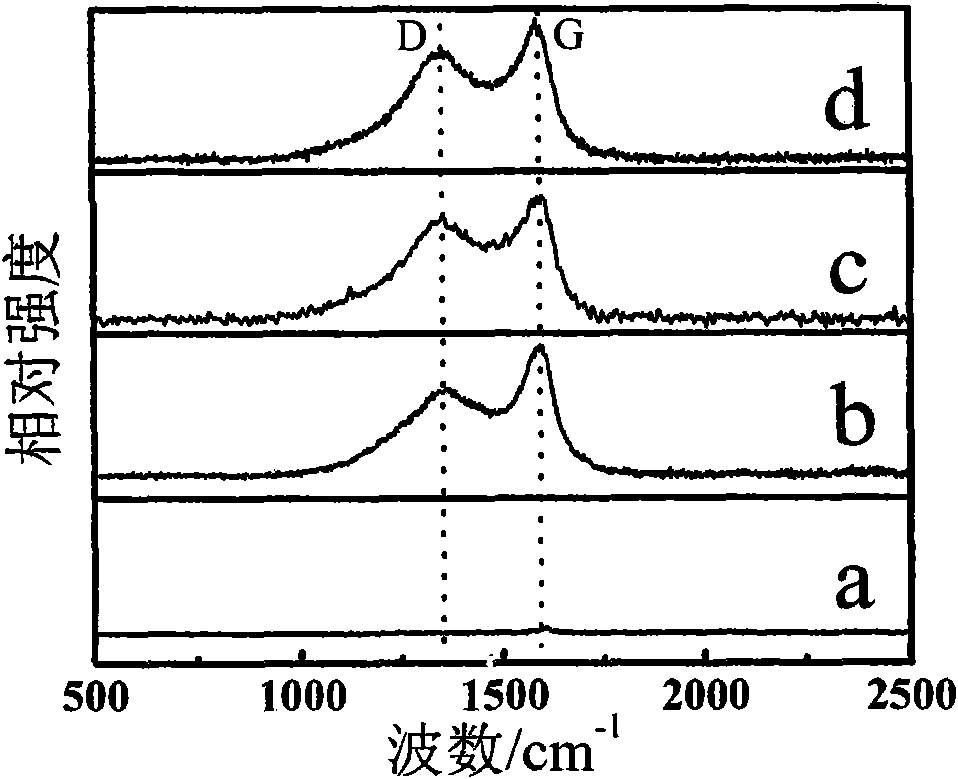

[0025] Carbon microtubes obtained by carbonizing willow catkins for 60 min under embodiment 3750° C., in order to test its catalytic oxygen reduction reaction performance, at 25° C., the rotating disk electrode linear voltammetry curve of the above carbon microtubes (RED ) and the linear voltammetry curve (RRED) of the rotating disk ring electrode. The obtained carbon microtube 5 mg was ultrasonically dispersed in 5 mL of water to obtain a 1.0 mg / mL catalyst solution, and the obtained catalyst solvent (40 μL) was added dropwise on the surface of the glassy carbon electrode, dried at room temperature and then added dropwise with 0.5 μL of Nafion, Place it at room temperature for 12 hours until it is completely dry, and the test is carried out in an oxygen-saturated 1mol / L NaOH electrolyte. The test results show that this material has good performance in catalytic oxygen reduction reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com