Method for producing fertilizer from paper-making black liquor

A technology for papermaking black liquor and black liquor, applied in the directions of organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of secondary pollution, long treatment period, environmental pollution, etc., and achieve thorough purification treatment, low operating costs, and reduced felling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

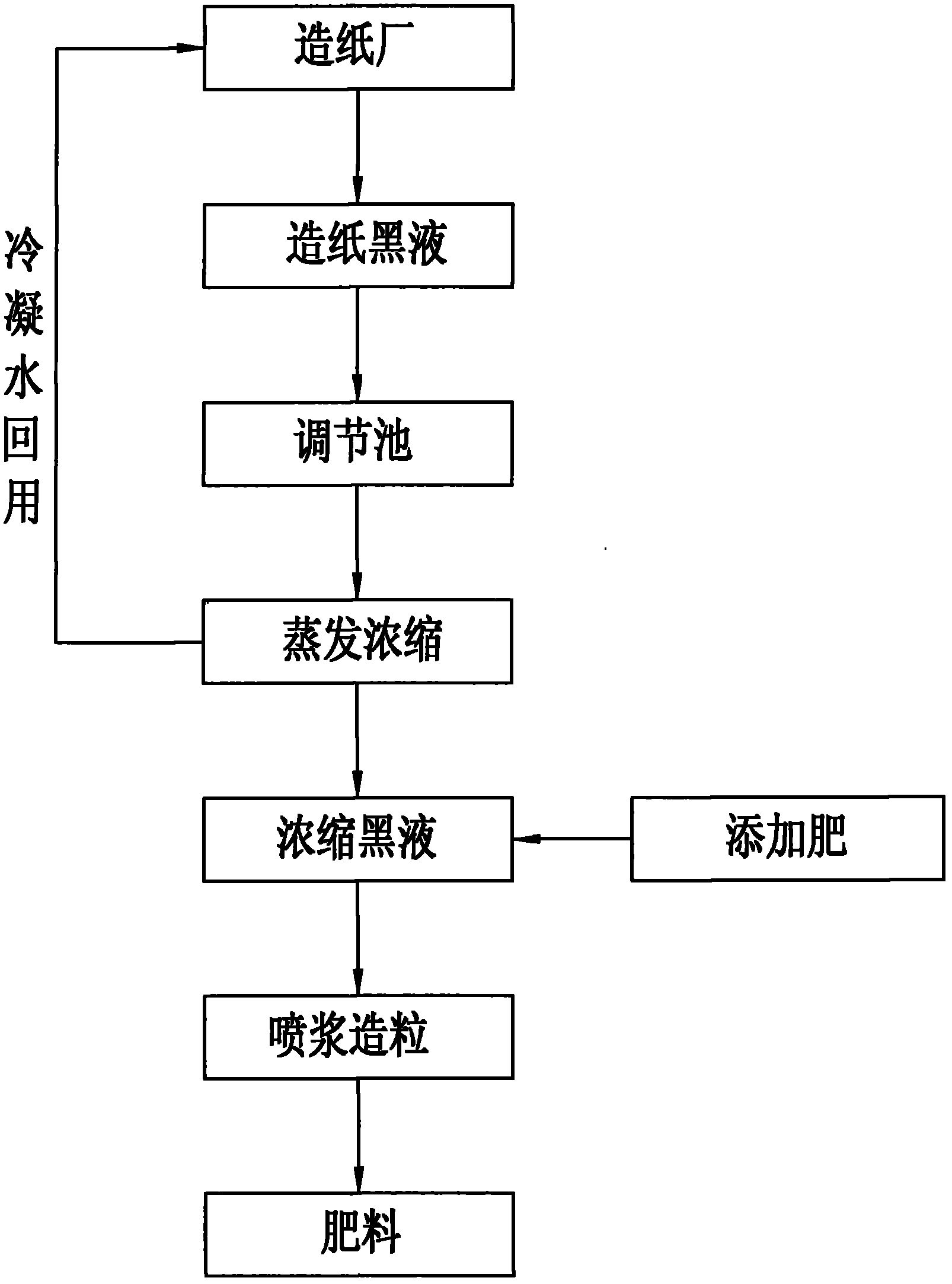

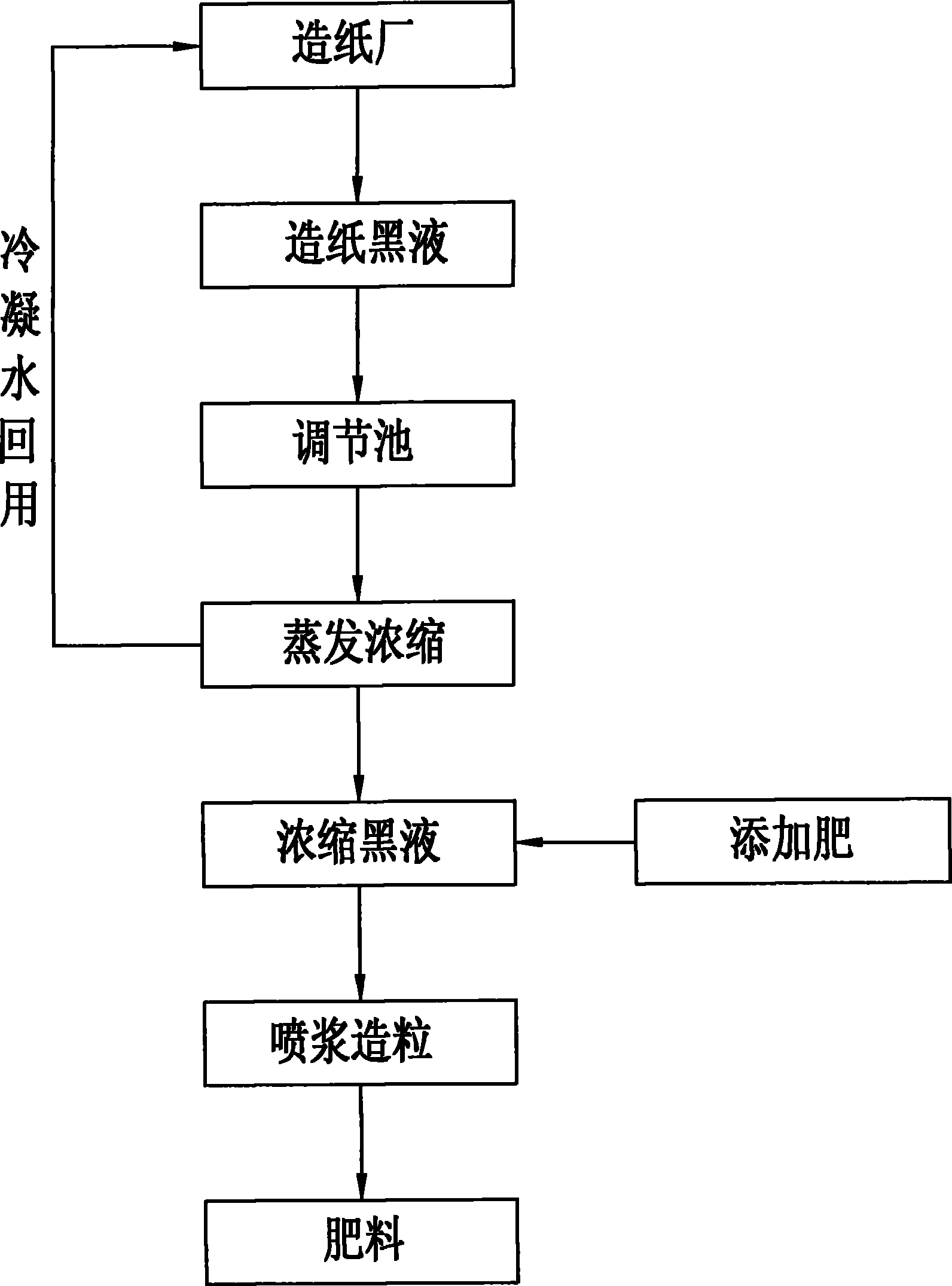

[0019] The method for making fertilizer from papermaking black liquor comprises the following steps in turn:

[0020] Black liquor adjustment step: introduce the papermaking black liquor into the adjustment tank, and use a biological method to reduce the pH value of the black liquor to 7-9; in this embodiment, the biological method is a biological acidification bacteria method, using The biological flora reduces the pH value of papermaking black liquor.

[0021] Black liquor concentration step: the adjusted black liquor is evaporated and concentrated, and the solid content of the black liquor after concentration is 20% to 90%; the evaporation adopts a heating evaporation method or a negative pressure evaporation method; the condensed water produced during the evaporation process can be recycle and re-use.

[0022] Shotcrete granulation step: Send the concentrated black liquor to a granulator for spray granulation to produce fertilizer. In this step, chemical fertilizer raw m...

Embodiment 2

[0025] The method for making fertilizer from papermaking black liquor comprises the following steps in turn:

[0026] Black liquor adjustment step: introducing the papermaking black liquor into the adjustment tank, and reducing the pH value of the black liquor to 7-9 by chemical method; the chemical method is an acid neutralization method.

[0027] Black liquor concentration step: the adjusted black liquor is evaporated and concentrated, and the solid content of the black liquor after concentration is 20% to 90%; the evaporation adopts a heating evaporation method or a negative pressure evaporation method; the condensed water produced during the evaporation process can be recycle and re-use.

[0028] Shotcrete granulation step: Send the concentrated black liquor to a granulator for spray granulation to produce fertilizer.

[0029] This fertilizer making method fully utilizes the organic matter in the papermaking black liquor, which can be used as a fertilizer or as a raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com