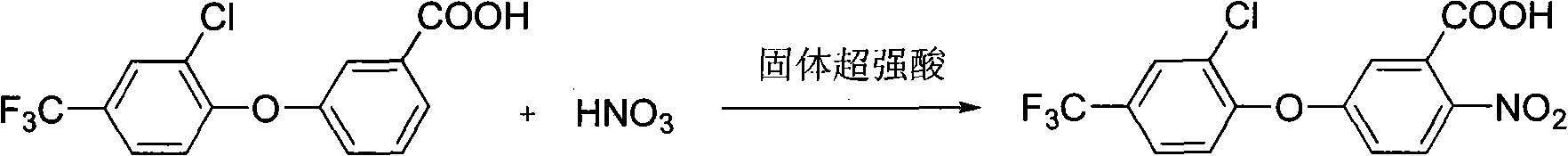

Method for preparing acifluorfen by catalyzing and nitrifying with solid super acid

A technology of solid super acid and acifluorfen, which is applied in the field of catalytic nitration of 3-[2-chloro-4-phenoxy]benzoic acid to prepare acifluorfen, which can solve the difficulties of waste acid recovery and reuse, A large amount of acid-containing wastewater, corrosion equipment and other problems, to achieve the effect of reusable environmental pollution, high catalytic activity, easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: SO 4 2- / ZrO 2 Preparation of Solid Superacid Catalyst

[0015] Take 40g of zirconium oxychloride solid, and configure it into a 10% zirconium oxychloride aqueous solution with deionized water. While stirring at room temperature, concentrated ammonia water was slowly added dropwise therein to adjust the pH to 9-10, a large amount of precipitates were precipitated, and the formed precipitates were aged at room temperature for 20 h. After aging, filter and wash the filter cake to be free of Cl - (Detected with 0.1mol / L silver nitrate solution) until detected. The filter cake was dried at 110°C for 14h, impregnated with 0.25mol / L sulfuric acid at a ratio of 5mL / g for 1h, dried at 110°C overnight after filtration, ground to 100 mesh, roasted at 550°C for 3h, taken out and placed in Cool in a desiccator to obtain 14g SO 4 2- / ZrO 2 .

Embodiment 2

[0016] Example 2: SO 4 2- / TiO 2 Preparation of Solid Superacid Catalyst

[0017] Take 30g TiCl 4 Add slowly to 0.2 mol / L hydrogen chloride deionized aqueous solution at 0°C to form a 20% solution. Slowly add concentrated ammonia water dropwise under stirring at room temperature to adjust the pH to 9-10, a large amount of precipitates are precipitated, and the formed precipitates are aged at room temperature for 20 h. After aging, filter and wash the filter cake to be free of Cl - Until it is detected (detected with 0.1mol / L silver nitrate solution), the filter cake is dried at 110°C for 14h, impregnated with 0.25mol / L sulfuric acid at a ratio of 10mL / g for 1h, filtered and baked at 110°C Dry overnight, grind to 200 mesh, bake at 500°C for 3 hours, take it out and put it in a desiccator to cool, and obtain 11.7g SO 4 2- / TiO 2 .

Embodiment 3

[0018] Example 3: SO 4 2- / Fe 2 o 3 Preparation of Solid Superacid Catalyst

[0019] Take 100g of ferric nitrate hydrate, and use deionized water to configure a 10% ferric nitrate aqueous solution. Slowly add concentrated ammonia water dropwise under stirring at room temperature to adjust the pH to 9-10, a large amount of precipitates are precipitated, and the formed precipitates are aged at room temperature for 20 h. After aging, filter and wash the filter cake to be free of Cl - Until it is detected (detected with 0.1mol / L silver nitrate solution), the filter cake is dried at 110°C for 14h, impregnated with 0.25mol / L sulfuric acid at a ratio of 15mL / g for 2h, filtered and baked at 110°C Dry overnight, grind to 300 mesh, bake at 500°C for 3 hours, take it out and put it in a desiccator to cool, and get 20g SO 4 2- / Fe 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com