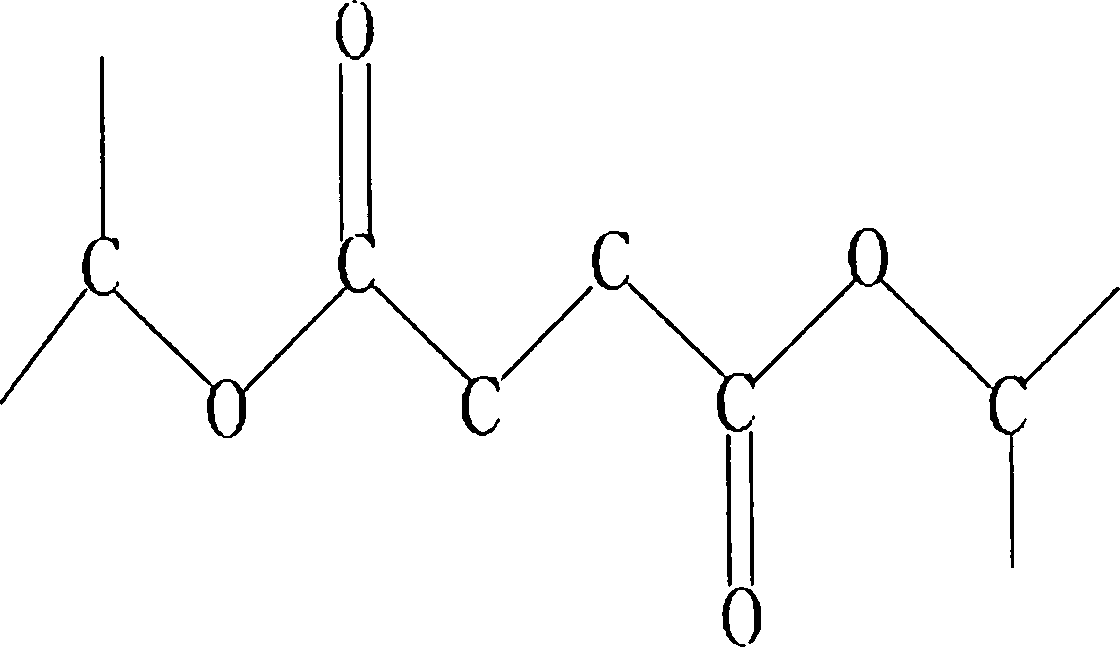

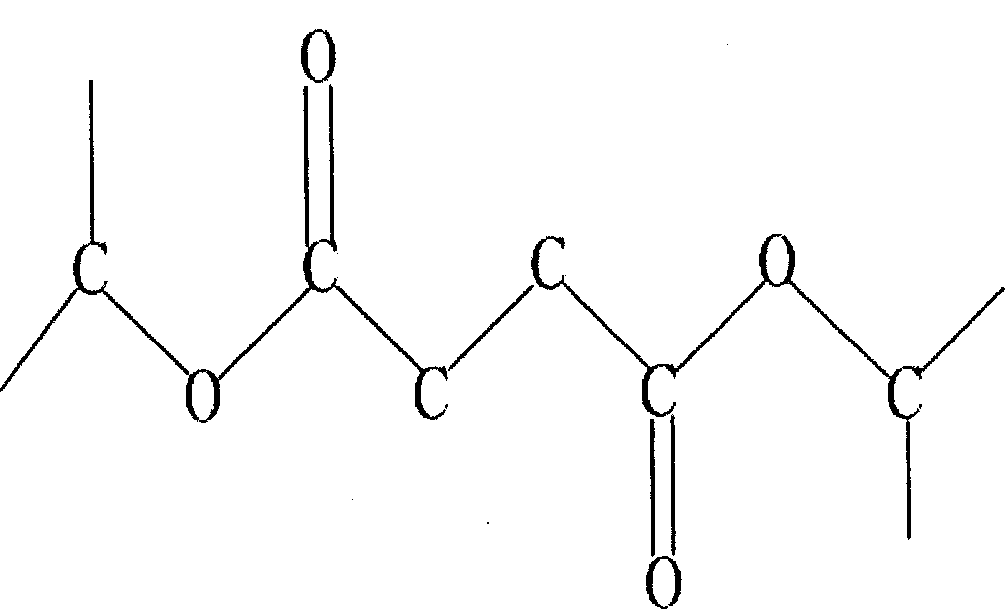

Diisopropyl succinate and intermittent preparation method thereof

A technology of diisopropyl succinate and succinic acid is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of large materials and energy consumption, large equipment, large investment, etc. , to achieve the effect of small investment, small number of equipment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

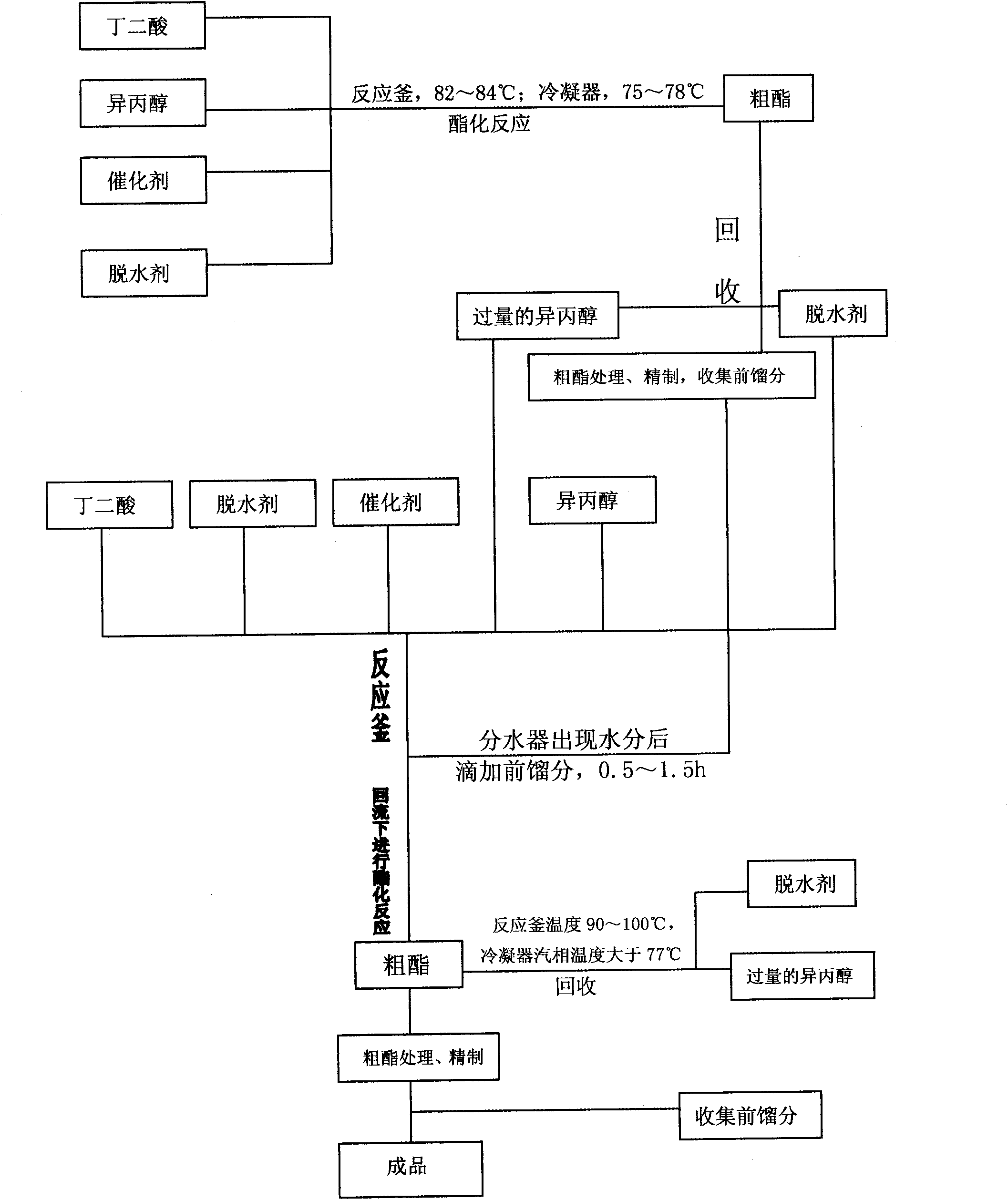

Method used

Image

Examples

Embodiment 1

[0039] (1) with 140 kilograms of succinic acid, 250 kilograms of Virahol, 2.1 kilograms of 98% sulfuric acid and 70 kilograms of toluene, add the esterification reactor that has a condenser and a water trap at the top of the fractional distillation column, be heated to reaction The temperature of the kettle is 83°C, the temperature of the vapor phase of the condenser is 76.5±0.5°C, and under reflux, the esterification reaction is carried out until the water separator has no water out, and then the temperature of the reactor is gradually increased to 98°C, and the temperature of the vapor phase of the condenser is greater than At 77°C, the dehydrating agent and excess isopropanol in the reclaimer were recovered, and then the crude ester generated by the esterification was post-treated and refined, and 52 kg of front distillate was collected;

[0040] (2) dehydrating agent and excessive Virahol and 140 kilograms of succinic acid, 150 kilograms of Virahol, 2.1 kilograms of 98% sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com