Application of membrane electrode in basic anion exchange membrane fuel cell

An anion exchange membrane, alkaline anion technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of high cost of precious metal catalysts, reduce battery performance, increase battery internal resistance, etc., to improve battery efficiency and conductivity. Reduce and improve the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

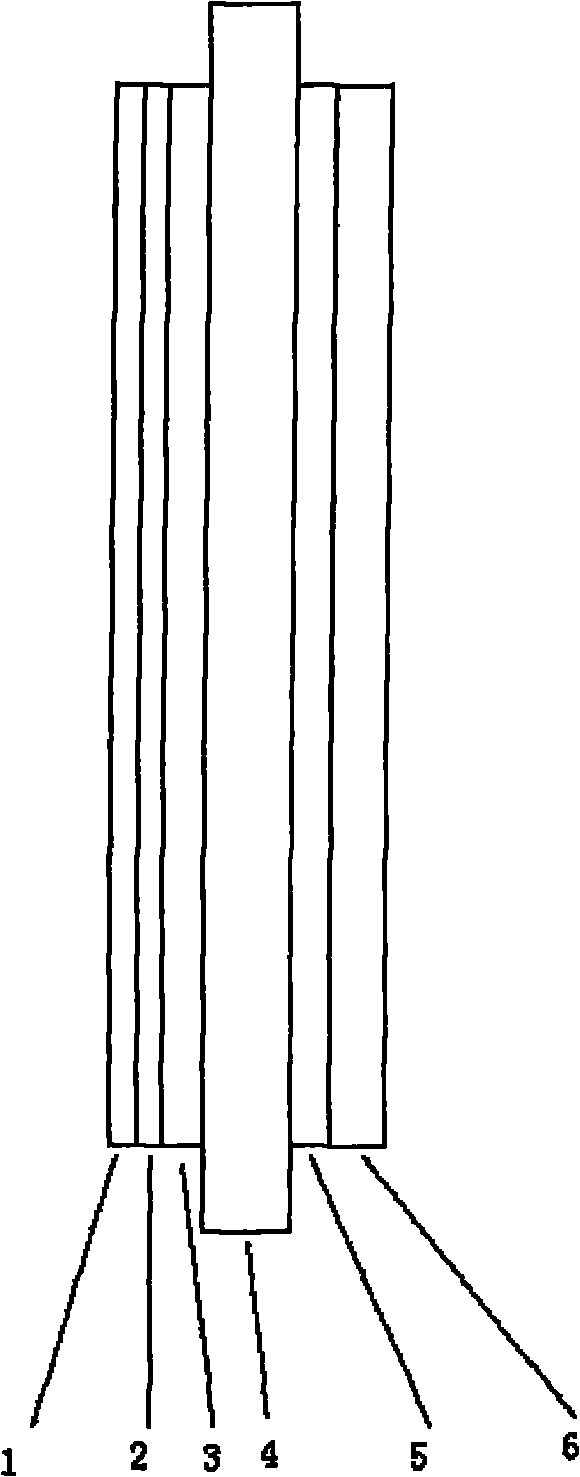

[0028] The structure of the membrane electrode is as figure 1 As shown, there are 6 parts including anode conductive porous substrate, anode microporous layer, anode catalyst layer, anion exchange membrane, cathode carbon material layer and cathode conductive porous substrate.

[0029] Membrane electrodes are prepared by the following process:

[0030] Anion-exchange membrane pretreatment: the self-made quaternary ammonium salt-type anion-exchange membrane is converted into an OH-type anion-exchange membrane by ion exchange, soaked in deionized water for cleaning, and cut into slices of appropriate size when used;

[0031] Preparation of the anode: PTFE is used to impregnate the commercially available carbon paper of SGL Company for hydrophobic treatment, and the mass percentage of PTFE after treatment is 15%. Commercial XC-72 activated carbon powder is dispersed in ethanol, and the slurry is coated on the above-mentioned carbon paper to make a microporous layer. Commerciali...

Embodiment 2

[0040] The structure of the membrane electrode is as figure 1 As shown, there are 6 parts including anode conductive porous substrate, anode microporous layer, anode catalyst layer, anion exchange membrane, cathode carbon material layer and cathode conductive porous substrate.

[0041] Membrane electrodes are prepared by the following process:

[0042] Wherein, anode, anion exchange membrane obtaining method are with embodiment 1;

[0043]Preparation of cathode: use PTFE to impregnate commercial SGL carbon paper for hydrophobic treatment, the mass percentage of PTFE is between 20% and 70%; disperse commercial carbon nanotubes in ethanol to prepare a slurry, and then brush evenly Make cathode on above-mentioned carbon paper; The load of this cathode carbon material is 4mg / cm 2 ;

[0044] Membrane electrode assembly and battery operating conditions are the same as in Example 1;

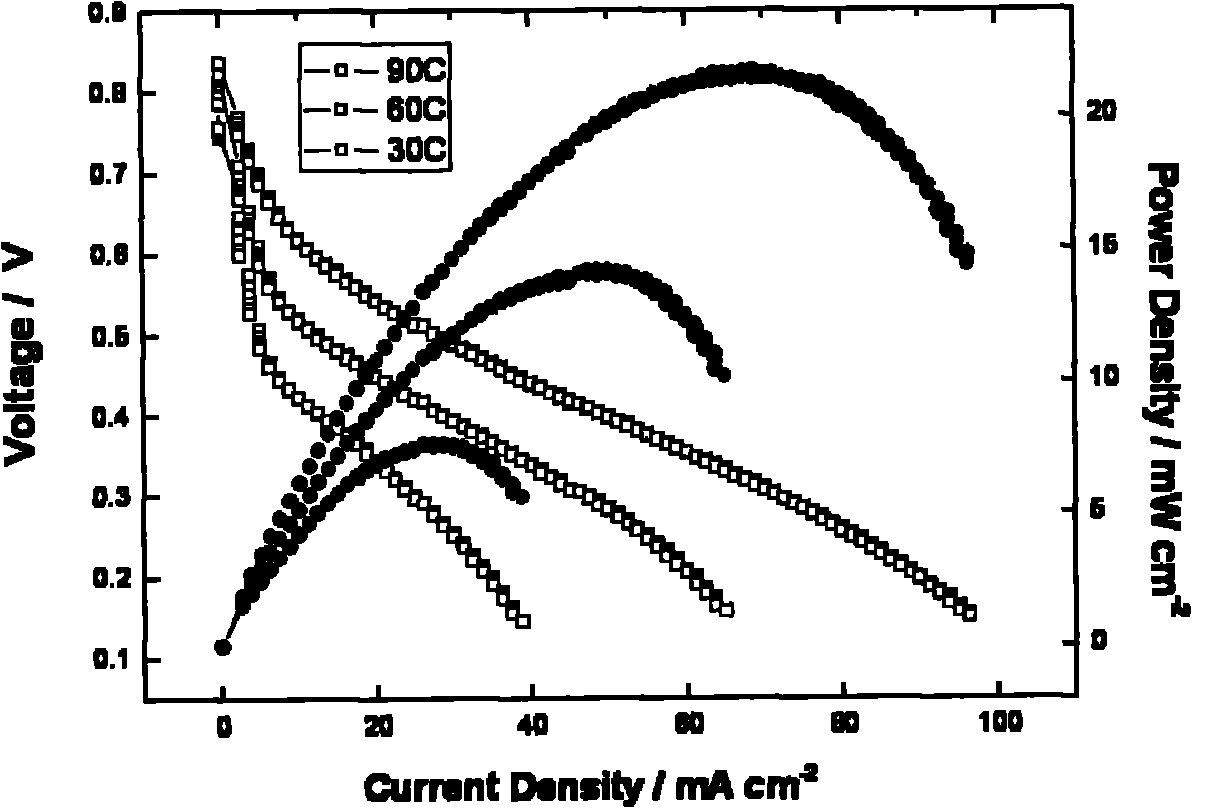

[0045] The IV polarization curve of the battery is shown in image 3 As shown, the peak power d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com