Low-platinum cathode catalyst layer used for fuel cell and application thereof

A cathode catalysis and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of few gas transmission channels, insufficient activity, and small contact area between electrocatalysts and proton exchange membranes, etc. Achieve the effects of fast migration speed, less Pt dosage, high catalyst utilization rate and high limiting current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

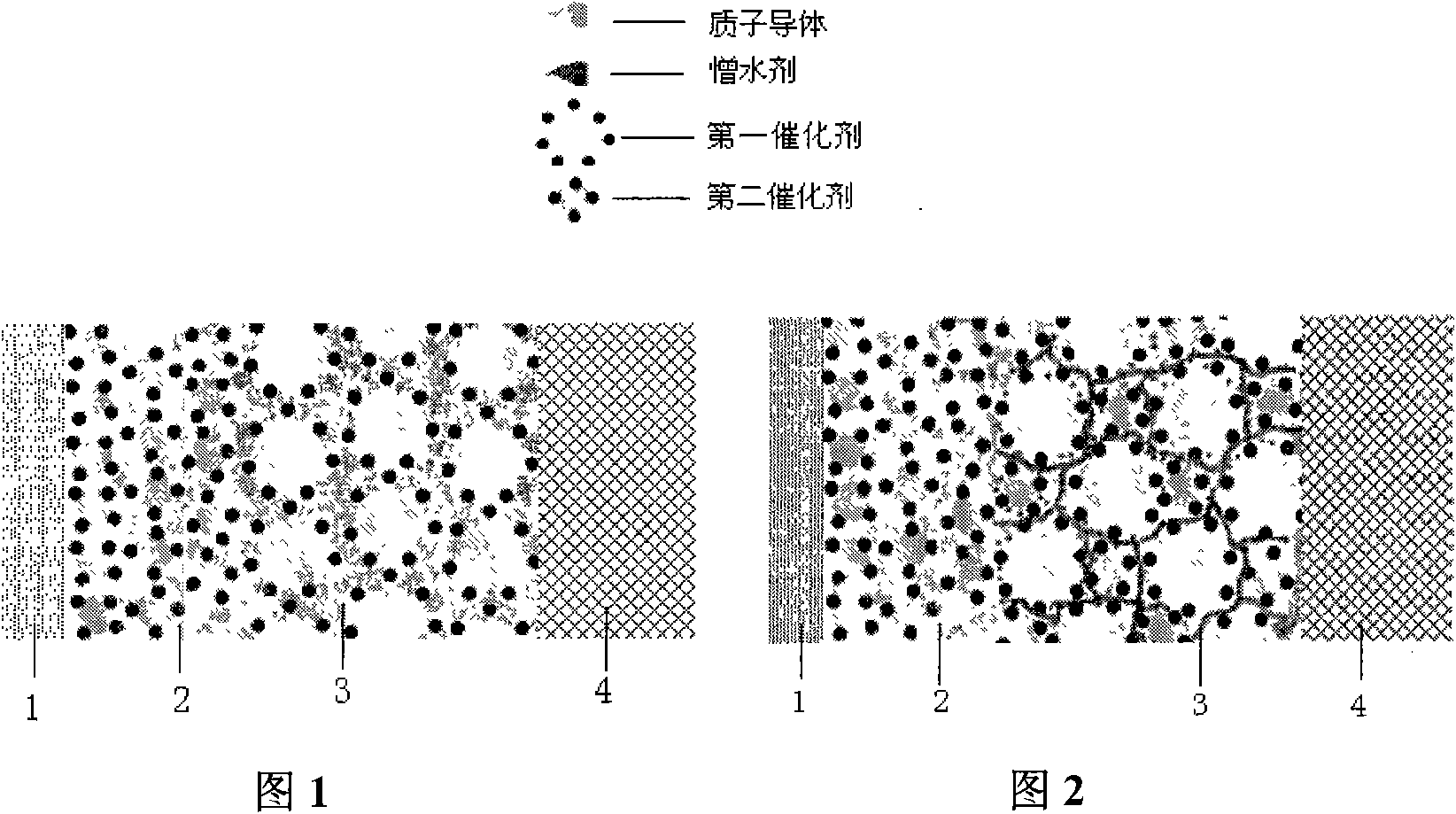

Method used

Image

Examples

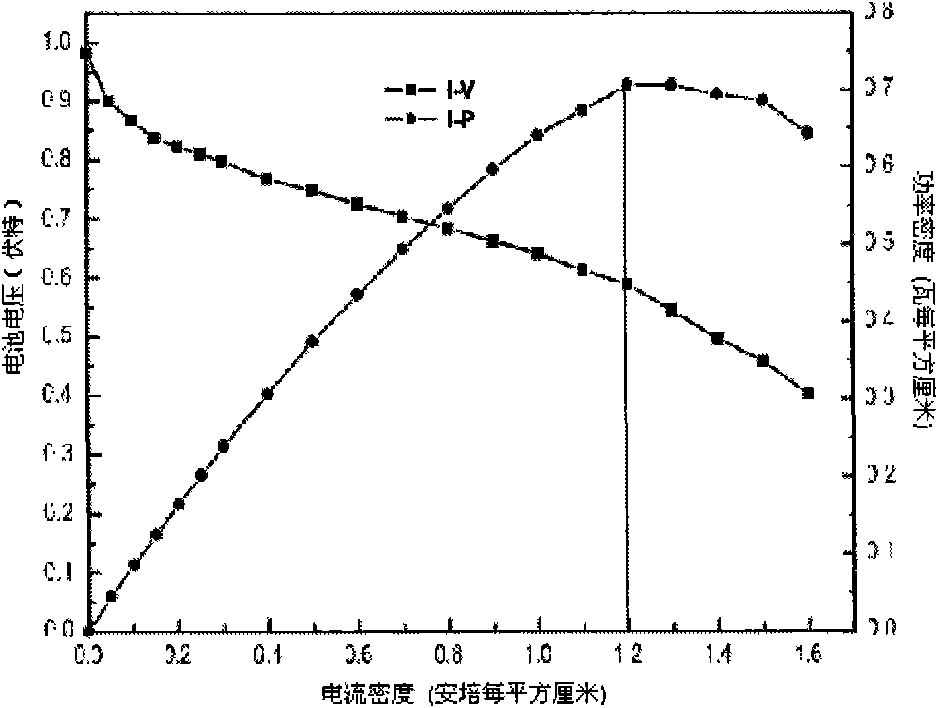

Embodiment 1

[0045] Prepare as follows:

[0046] 1) Preparation of the outer catalytic layer: use a primary balance to weigh the catalyst with a BET specific surface area of 235m 2 The Vulcan XC-72 of / g is the 70% Pt / C electrocatalyst (the first catalyst) of carrier, add a small amount of deionized water to fully wet the electrocatalyst, then add ethylene glycol according to 20 times of the electrocatalyst weight, in ultrasonic Ultrasonic oscillation at a frequency of 40KHz for 30min until completely mixed evenly, add 10% polyvinylidene fluoride emulsion according to the weight percentage of 30% of the weight of the outer catalytic layer, continue ultrasonic oscillation at a frequency of 40KHz for 30min until uniform, and make a slurry . Use Doctor Blade to uniformly coat this slurry on the surface of Toray carbon paper with microporous layer (MPL), then put the above-mentioned catalytic layer that is made into a roasting furnace, under N 2 Heating in the atmosphere at a heating rate ...

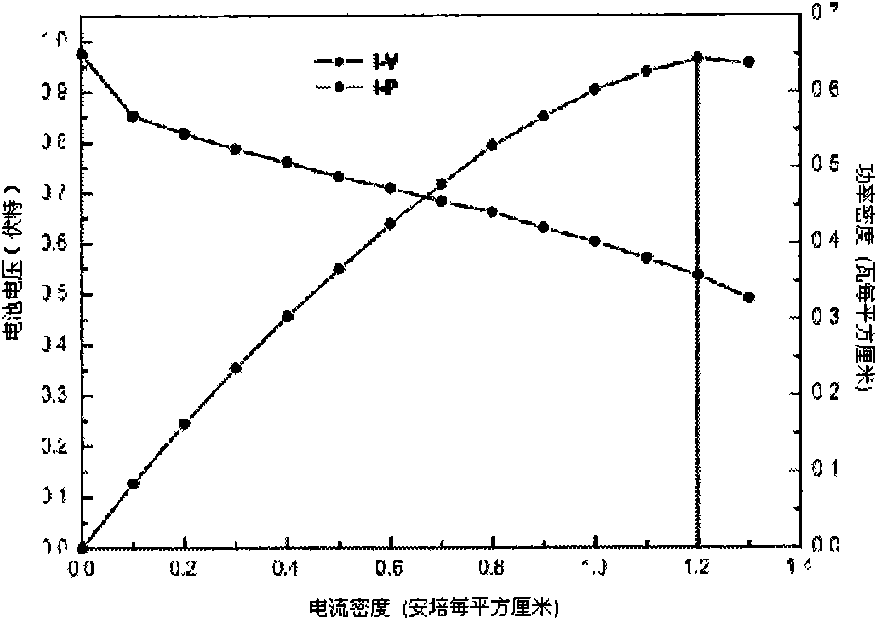

Embodiment 2

[0056] 1) Prepare the outer catalytic layer: use a primary balance to weigh 20% PtCo 2 o 3 / C (Pt: Co=9: 1 (atomic ratio)) first catalyst, wherein carrier C is that BET specific surface area is 50m 2 / g of highly conductive graphite, add a small amount of deionized water to completely wet the electrocatalyst, add ethylene glycol according to 30 times the weight of the electrocatalyst, and ultrasonically oscillate for 30 minutes at a frequency of 40KHz in the ultrasonic wave until it is completely mixed. 10% polytetrafluoroethylene (PTFE) emulsion was added to 50% of the weight of the layer, and continued to be ultrasonically oscillated at a frequency of 40KHz for 30min until uniform to form a slurry. After the prepared slurry was subjected to gel treatment in a constant temperature water margin at 90°C, the slurry was evenly coated on the surface of Toray carbon paper with a microporous layer using a plastic scraper, and then put into a roasting furnace, according to the exam...

Embodiment 3

[0061] 1) Preparation of the outer catalytic layer: first, 30% Pt / C (first catalyst) using Vulcan-XC 72 as a carrier and 60% PtTiO using Kejen carbon black as a carrier 2 / C (the second catalyst, Pt: Ti=9: 1 (atomic ratio)) is formulated as a uniform composite catalyst according to the mass ratio of 4: 1, and then according to composite catalyst: dispersant=1: 25 and composite electrocatalyst: PTFE =7:3 ratio, use the first electrocatalyst, the second electrocatalyst, three kinds of raw materials of glycerol and PTFE micropowder, prepare slurry according to the method for step 1) in the embodiment 1. After gel treatment of the prepared slurry in a constant temperature water at 90°C, use a 100-mesh nylon screen, and use a screen printing machine to uniformly screen print the prepared slurry on the coated microporous layer (MPL) , and take Toray carbon paper as the gas diffusion layer of the support, then put the prepared above-mentioned (microporous layer (MPL)+catalyst layer) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com