Method for removing boron and phosphorus in silicon at low temperature

A low-temperature, boron-phosphorous technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of special production technology for solar-grade high-purity silicon that is difficult to use in metallurgy, poor connection of purification methods, and inability to remove impurities simultaneously. , to achieve the effects of low equipment manufacturing requirements, shortened high-temperature treatment time, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

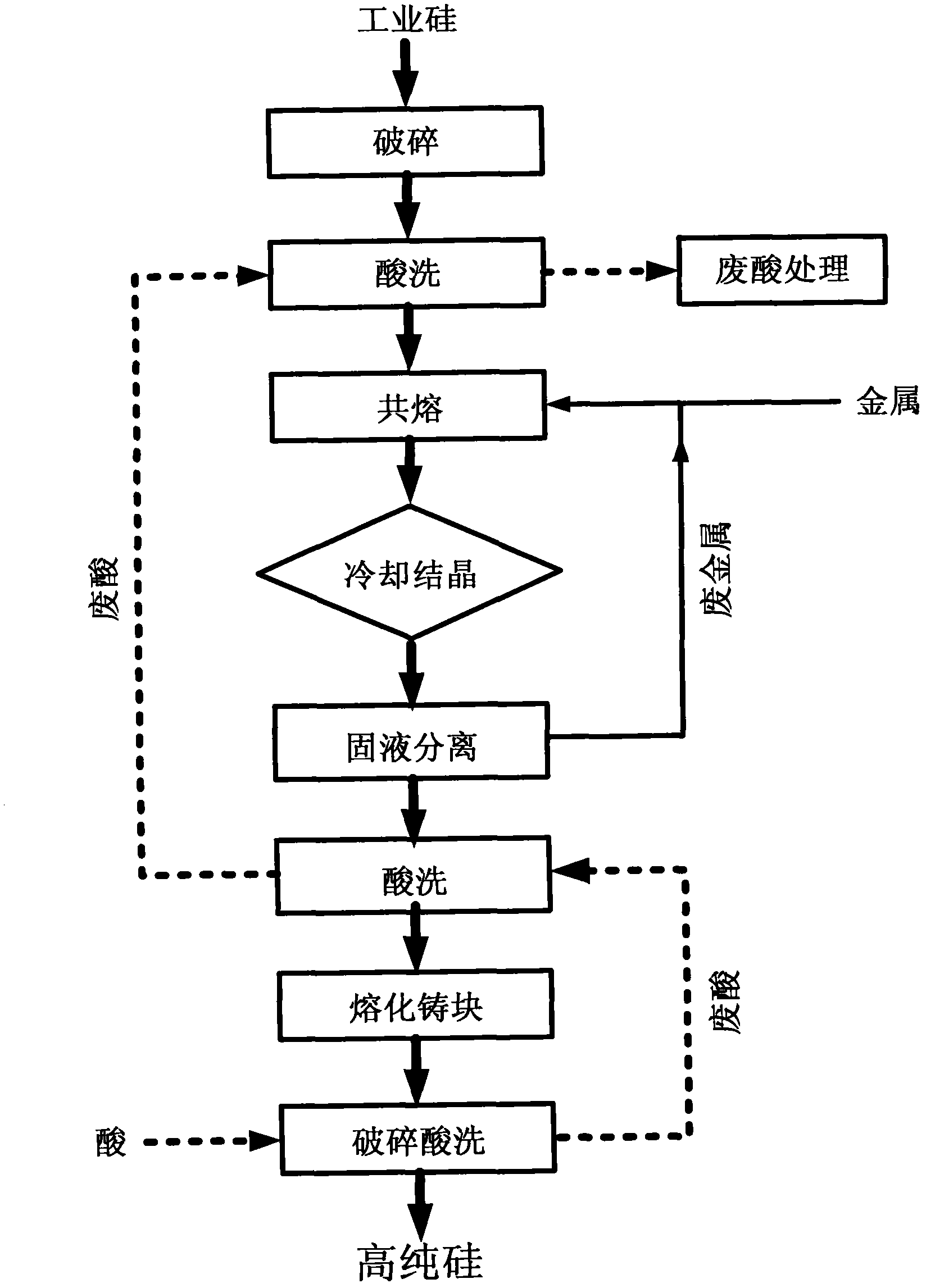

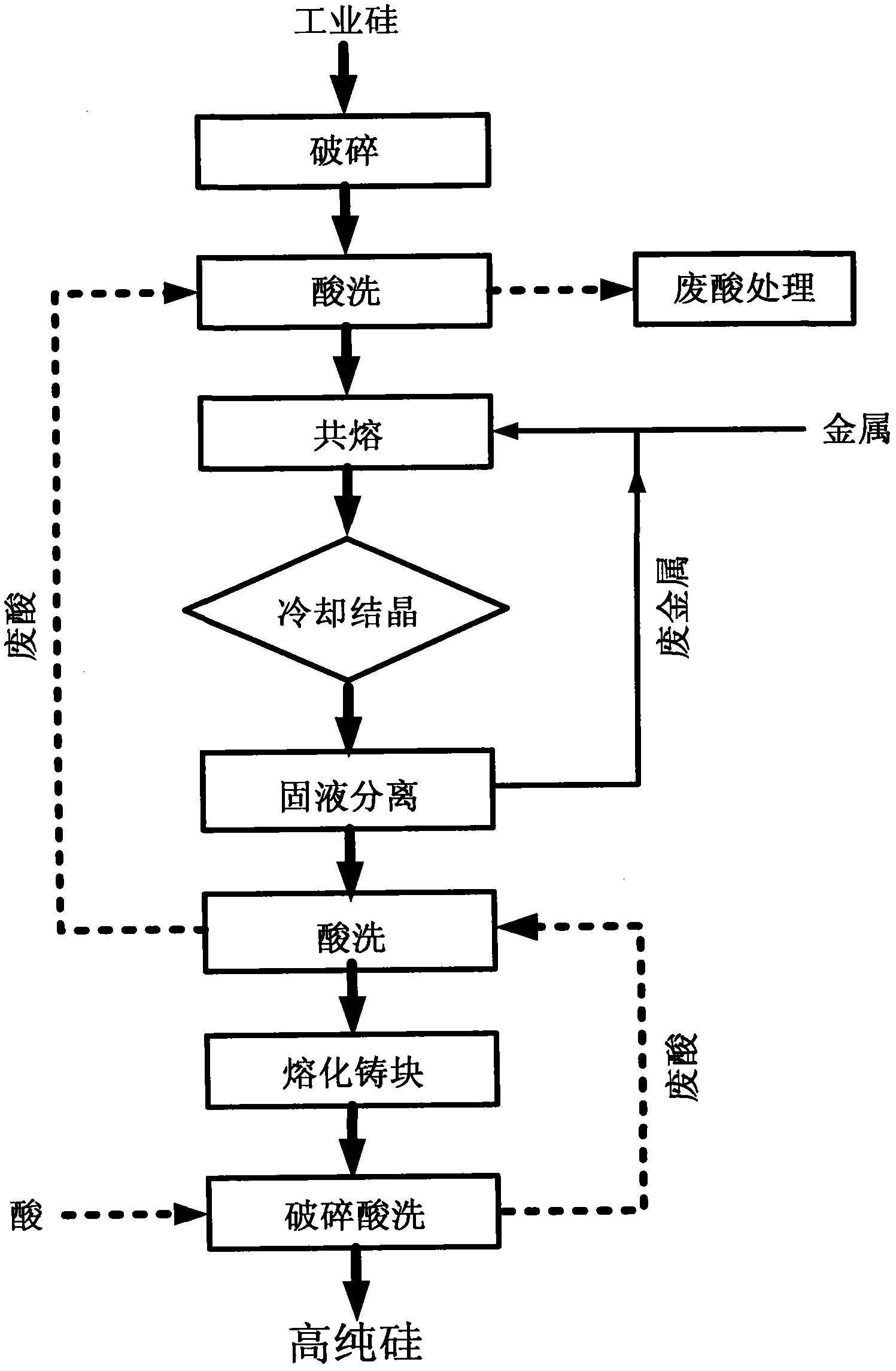

Method used

Image

Examples

Embodiment 1

[0028] Break 2g of metallurgical silicon (grade 1101, produced in Hunan) to below 500 microns, pickle with 5wt% hydrofluoric acid at 70°C for 6 hours, the weight ratio of silicon to acid is 1:20, rinse with deionized water after pickling , and dried to obtain pretreated silicon powder. The pretreated silicon powder is mixed with metal tin (purity 99.9wt%), heated to 1150°C to completely melt, and cooled to 600°C at 3.3°C / min to recrystallize the silicon. The silicon crystal was separated by centrifugation, pickled with dilute aqua regia (aqua regia:water:crude silicon weight ratio: 10:10:1), rinsed, and dried to obtain 1.95g of silicon crystal. The silicon crystals were melted, rapidly solidified into blocks, crushed, pickled, rinsed, and dried to obtain 1.91 g of high-purity silicon. The purification results are compared in Table 1.

[0029] Table 1

[0030] Impurity elements

[0031] Unit: ppmw

Embodiment 2

[0033] Break 2g of metallurgical silicon (grade 1101, produced in Hunan) to below 500 microns, pickle with 5wt% hydrofluoric acid at 70°C for 6 hours, the weight ratio of silicon to acid is 1:20, rinse with deionized water after pickling , and dried to obtain pretreated silicon powder. Mix the pretreated silicon powder with the centrifuged waste tin in Example 1, heat to 1150°C to completely melt, and cool to 600°C at 3.3°C / min to recrystallize the silicon. The silicon crystals were separated by centrifugation, pickled with dilute aqua regia (aqua regia:water:crude silicon weight ratio: 10:10:1), rinsed, and dried to obtain 1.90 g of silicon crystals. The silicon crystals were melted, rapidly solidified into blocks, crushed, pickled, rinsed, and dried to obtain 1.89 g of high-purity silicon. The purification results are compared in Table 2.

[0034] Table 2

[0035] Impurity elements

[0036] Unit: ppmw

Embodiment 3

[0038] Break 10g of metallurgical silicon (brand 1101, produced in Fujian) to below 500 microns, pickle with aqua regia at 70°C for 6 hours, the weight ratio of silicon to acid is 1:10, rinse with deionized water after pickling, and dry , to obtain pretreated silicon powder. The pretreated silicon powder is mixed with metal tin (purity 99.9wt%), heated to 1200°C to completely melt, and cooled to 600°C at 3.3°C / min to recrystallize the silicon. The silicon crystals were separated by centrifugation, pickled with dilute aqua regia (aqua regia:water:crude silicon weight ratio: 10:10:1), rinsed, and dried to obtain 9.84g of silicon crystals. The silicon crystals were melted, rapidly solidified into blocks, crushed, pickled, rinsed, and dried to obtain 9.75 g of high-purity silicon. The purification results are compared in Table 3.

[0039] table 3

[0040] Impurity elements

[0041] Unit: ppmw

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com