Preparation method and product of infrared stealth wave-absorbing composite protective paint

A protective coating, infrared technology, applied in the direction of radiation-absorbing coatings, epoxy resin coatings, coatings, etc., to achieve the effect of providing construction efficiency, stable product quality, and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: The preparation method of a kind of infrared stealth wave-absorbing composite protective coating provided by the present invention comprises the following steps:

[0053] (1) Raw material pretreatment:

[0054] Preparation of spherical ferrite magnets and zirconia as spheres used in ball mills;

[0055] Prepare indium tin oxide powder with a particle size between 0.1 and 2 microns for use,

[0056] Prepare zinc powder, nickel powder and graphite powder with an average diameter of 1-2 mm;

[0057] It is also possible to purchase raw materials that meet the requirements and directly use them in production;

[0058] The spherical ferrite magnet block wherein is sintered ferrite, and its diameter is 60~95mm; The diameter of described zirconia sphere is 5~30mm; The weight ratio of its filling amount is ferrite: zirconia=3: 1.

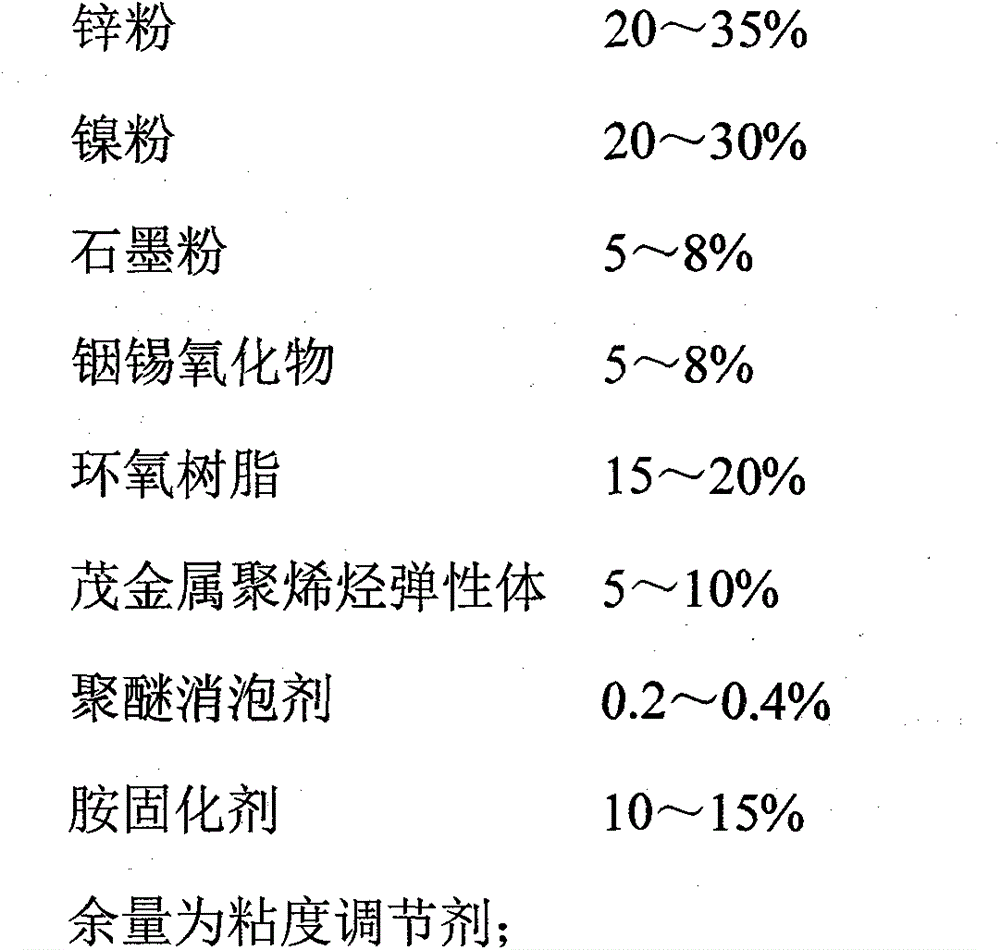

[0059] (2) Weighing raw materials:

[0060] Weigh raw materials according to the following weight percentages:

[0061]Zinc powde...

Embodiment 2

[0101] Example 2: The preparation method and coating provided in this implementation are basically the same as in Example 1, except that the weight percentages of the components used are different.

[0102] The preparation method of an infrared stealth wave-absorbing composite protective coating provided by the embodiment of the present invention comprises the following steps:

[0103] (1) Raw material pretreatment:

[0104] Preparation of spherical ferrite magnets and zirconia as spheres used in ball mills;

[0105] Prepare indium tin oxide powder with a particle size between 0.1 and 2 microns for use,

[0106] Prepare zinc powder, nickel powder and graphite powder with an average diameter of 1-2 mm;

[0107] It is also possible to purchase raw materials that meet the requirements and directly use them in production;

[0108] (2) Weighing raw materials:

[0109] Weigh raw materials according to the following weight percentages:

[0110] Zinc powder 20%

[0111] Nickel p...

Embodiment 3

[0143] Example 3: The preparation method and coating provided in this implementation are basically the same as those in Examples 1 and 2, except that the weight percentages of the components used are different. The difference is that:

[0144] In the preparation method of infrared stealth wave-absorbing composite protective coating,

[0145] (1) Raw material pretreatment

[0146] The spherical ferrite magnet block is sintered ferrite with a diameter of 95mm; the diameter of the zirconia sphere is 30mm;

[0147] (2) Weighing raw materials:

[0148] Weigh raw materials according to the following weight percentages:

[0149] Zinc powder 35%

[0150] Nickel powder 20%

[0151] Graphite powder 5%

[0153] Epoxy 15%

[0154] Metallocene Polyolefin Elastomer POE 5%

[0155] Polyether defoamer 0.4%

[0156] Amine curing agent 10%

[0157] The balance is a viscosity modifier;

[0158] (3) Powder grinding: Add zinc powder, nickel powder, graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com