Anti-charged dust device used on surface of optical system or solar cell

A technology of solar cells and optical systems, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of optical system image quality impact, limit the application of dust removal electric curtains, etc., achieve good dust prevention and dust removal effects, good hydrophobicity and natural Cleaning function, effect of increased roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

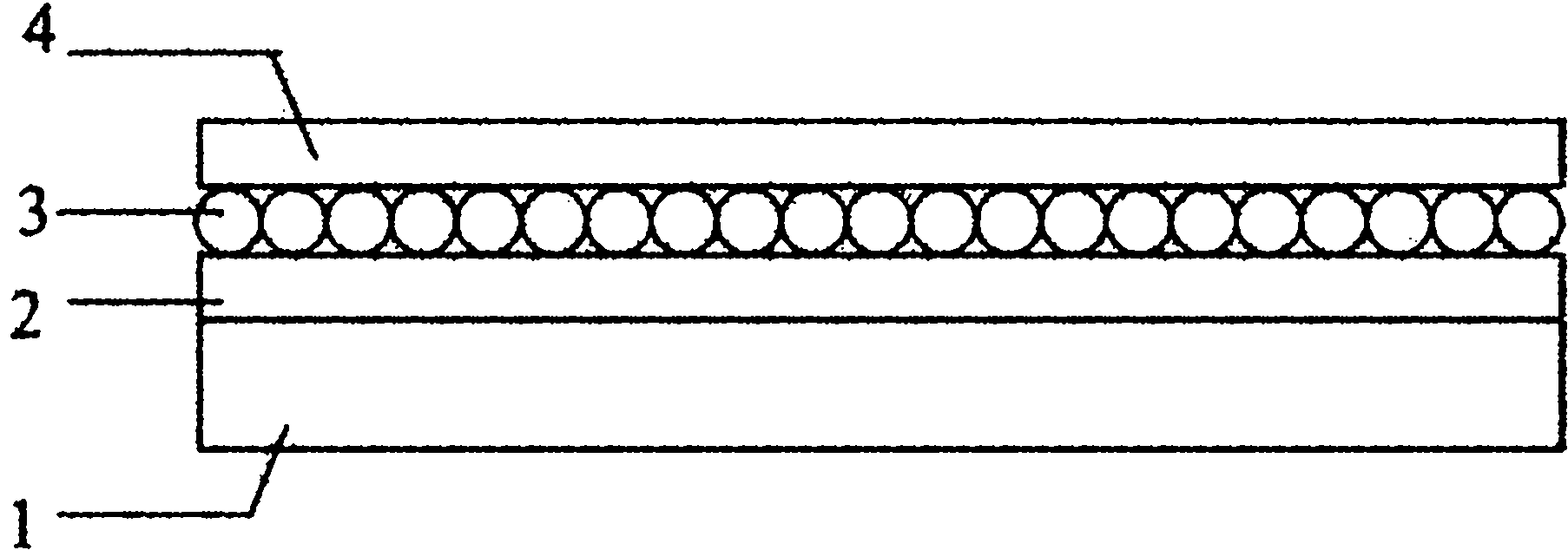

[0025] Such as figure 1 As shown, a device for preventing charged dust on the surface of a solar cell consists of a substrate 1, and an indium tin oxide layer 2, a titanium dioxide nanoparticle array layer 3, and a fluoropolymer thin film layer formed sequentially on the substrate 1 4 composition.

[0026] Among them, the substrate 1 is a p-type single crystal silicon wafer used on the surface of the solar cell; the indium tin oxide layer 2 is a transparent indium tin oxide layer; , the titanium dioxide nanoparticle array layer can achieve a roughness of 2; the fluorine-containing polymer film layer 4 is a polytetrafluoroethylene layer with a thickness of 5 microns.

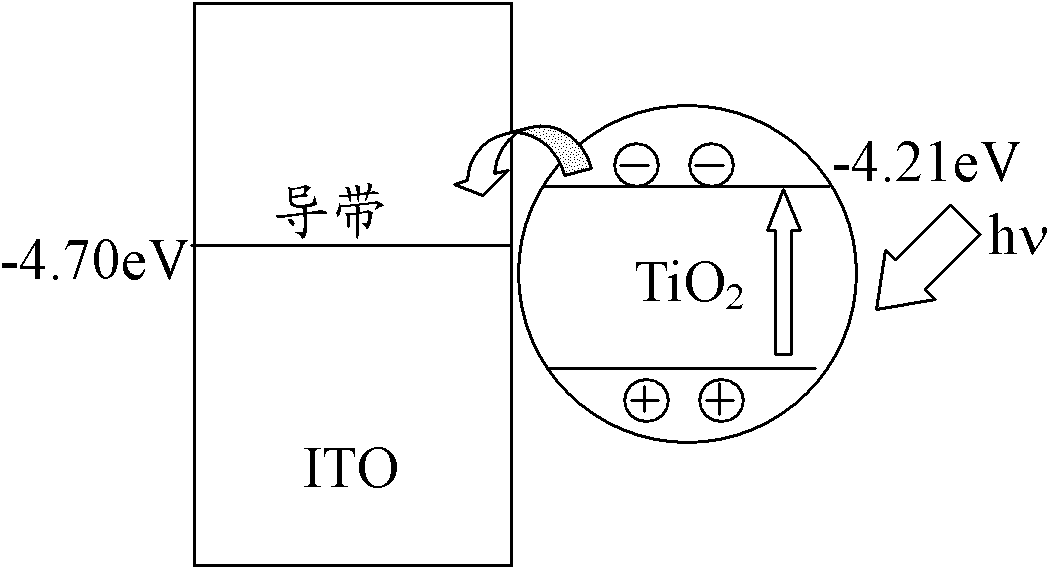

[0027] Such as figure 2As shown, under ultraviolet light, the conduction band energy level of titanium dioxide in titanium dioxide nanoparticle array layer 3 is -4.21eV, while the conduction band energy level of indium tin oxide in indium tin oxide layer 2 is -4.7eV, and the conduction band energy level of ind...

Embodiment 2

[0029] A device for preventing charged dust on the surface of an optical system is composed of a substrate 1, an indium tin oxide layer 2, a titanium dioxide nanoparticle array layer 3 and a fluoropolymer film layer 4 sequentially formed on the substrate 1.

[0030] Wherein, the substrate 1 is K9 glass used for the surface of the optical system; the indium tin oxide layer 2 is a transparent indium tin oxide layer; the particle diameter of titanium dioxide in the titanium dioxide nanoparticle array layer 3 is 50 nm, and the density of the titanium dioxide particle array layer is close-packed. The roughness is 2; the fluorine-containing polymer film layer 4 is a polyvinylidene fluoride layer, and the thickness is less than 100nm.

[0031] Its mechanism is the same as that in Example 1, but the resistant temperature ranges of polyvinylidene fluoride and polytetrafluoroethylene in the fluorine-containing polymer layer are different. The resistant temperature of vinylidene fluoride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com