Preparation method of high-hydrophobicity and self-cleaning wood

A self-cleaning, wood-based technology, applied in wood treatment, impregnation of wood, wood impregnation, etc., can solve the problems of complex treatment process, change of wood color, high toxicity of modifiers, etc., and achieve good mechanical properties, strong anti-corrosion performance, and stable dimensions good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

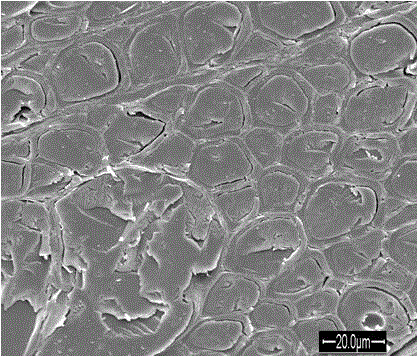

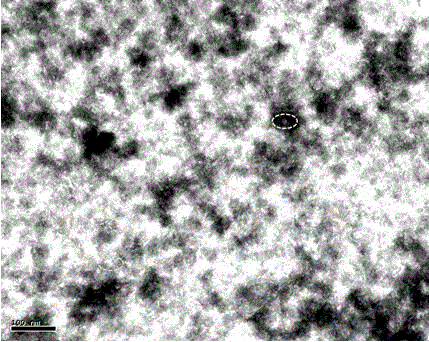

[0035]The preparation method of the highly hydrophobic self-cleaning characteristic wood of the present embodiment is carried out according to the following steps: 1. Weigh 49% to 99% of fluorine-containing polymerizable monomers, 0 to 40% of unsaturated monomers, 0.5 %~10% fluorine-containing modified nano POSS particles and 0.5%~1% initiator, then stir and dissolve the nano POSS particles in tetrahydrofuran (POSS accounts for 10wt% by weight of THF), and finally mix the above raw materials evenly , to obtain the impregnation solution; 2. Add the wood and the impregnation solution obtained in step one to the reaction tank, and immerse the wood in the impregnation solution. After the reaction tank is sealed, air is introduced into it to make the pressure in the reaction tank Reach 0.8MPa~1MPa, and keep it for 20min~30min; 3. Reduce the pressure of the reaction tank to normal pressure, take out the wood, then wrap the impregnated wood with aluminum foil, and place it at room tem...

specific Embodiment approach 2

[0038] The difference between this embodiment and specific embodiment 1 is that in step 1, 54.1% to 94.4% of fluorine-containing polymerizable monomers, 2.5% to 40% of unsaturated monomers, 2.5% to 5% of Fluorine modified nano POSS particles and 0.6% to 0.9% initiator. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] The difference between this embodiment and the specific embodiment one is that in step one, 79.2% of fluorine-containing polymerizable monomers, 10% of unsaturated monomers, 10% of fluorine-containing modified nano POSS particles and 0.8% initiator. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com