Valve-controlled sealed lead-acid accumulator for electric vehicle

A technology for lead-acid batteries and electric vehicles, which can be used in battery components, electrode carriers/collectors, secondary battery repair/maintenance, etc., and can solve problems such as difficult to achieve goals, environmental pollution, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

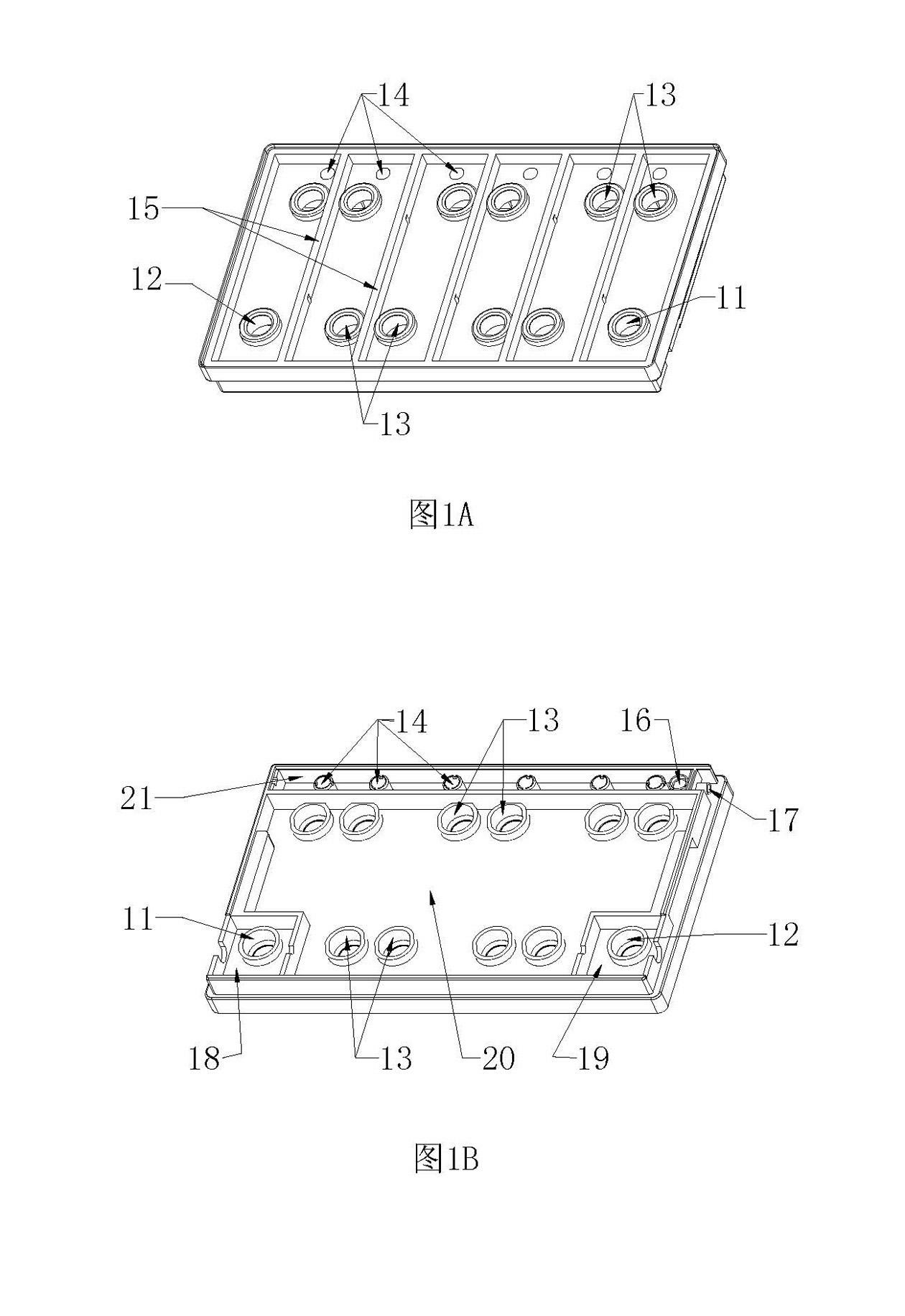

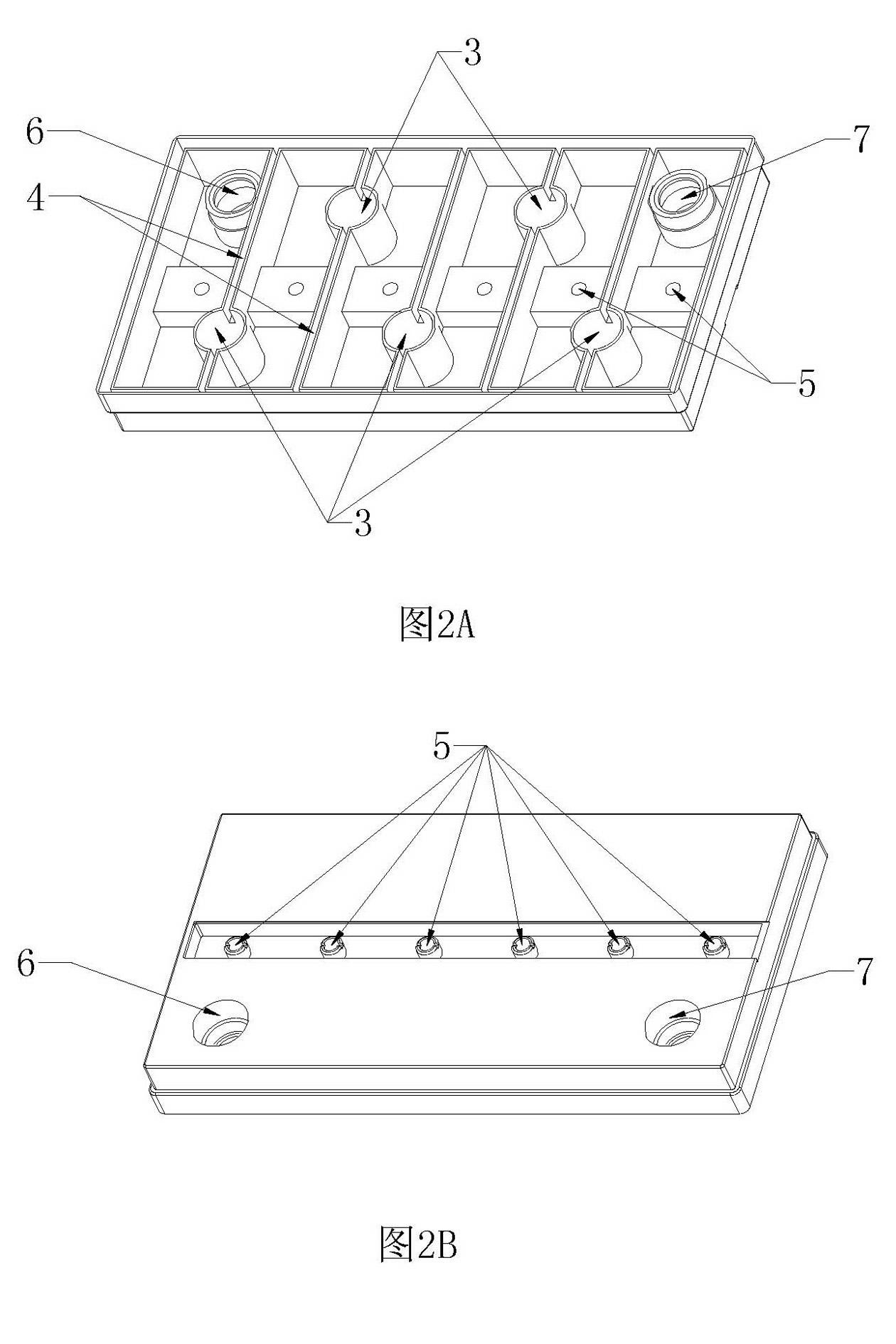

[0041]The present invention takes a 12V100Ah storage battery as an example, and the designed external dimensions of the battery are 299.6mm in length, 173mm in width and 220mm in height. The material of the battery tank cover is made of ABS resin, and the connection of the tank cover is welded by hot melting method. The specific decomposition is that the height of the battery tank is 195mm, divided into 6 cells, the wall thickness between the cells of the battery tank is 2mm, the thickness of the outer wall around the battery tank is 5mm, and the demoulding slope is less than 0.3%. The battery cover is 25mm high, divided into upper and lower parts, the upper part is 15mm high, the lower part is 10mm high, and the middle spacer is 3mm thick. The lower part of the battery cover is divided into 6 cells corresponding to the battery slot, and the wall thickness between the cells is 5mm. The thickness of the outer wall around it is 7mm. The upper part of the battery cover is a seale...

Embodiment 2

[0050] Embodiment 2 and Embodiment 1 have exactly the same shape and size design of the battery tank cover, the same pole structure, the same voltage monitor and temperature monitor, the same grid is used to manufacture the positive and negative plates, and the battery assembly method is the same. The differences from Example 1 are described in detail below.

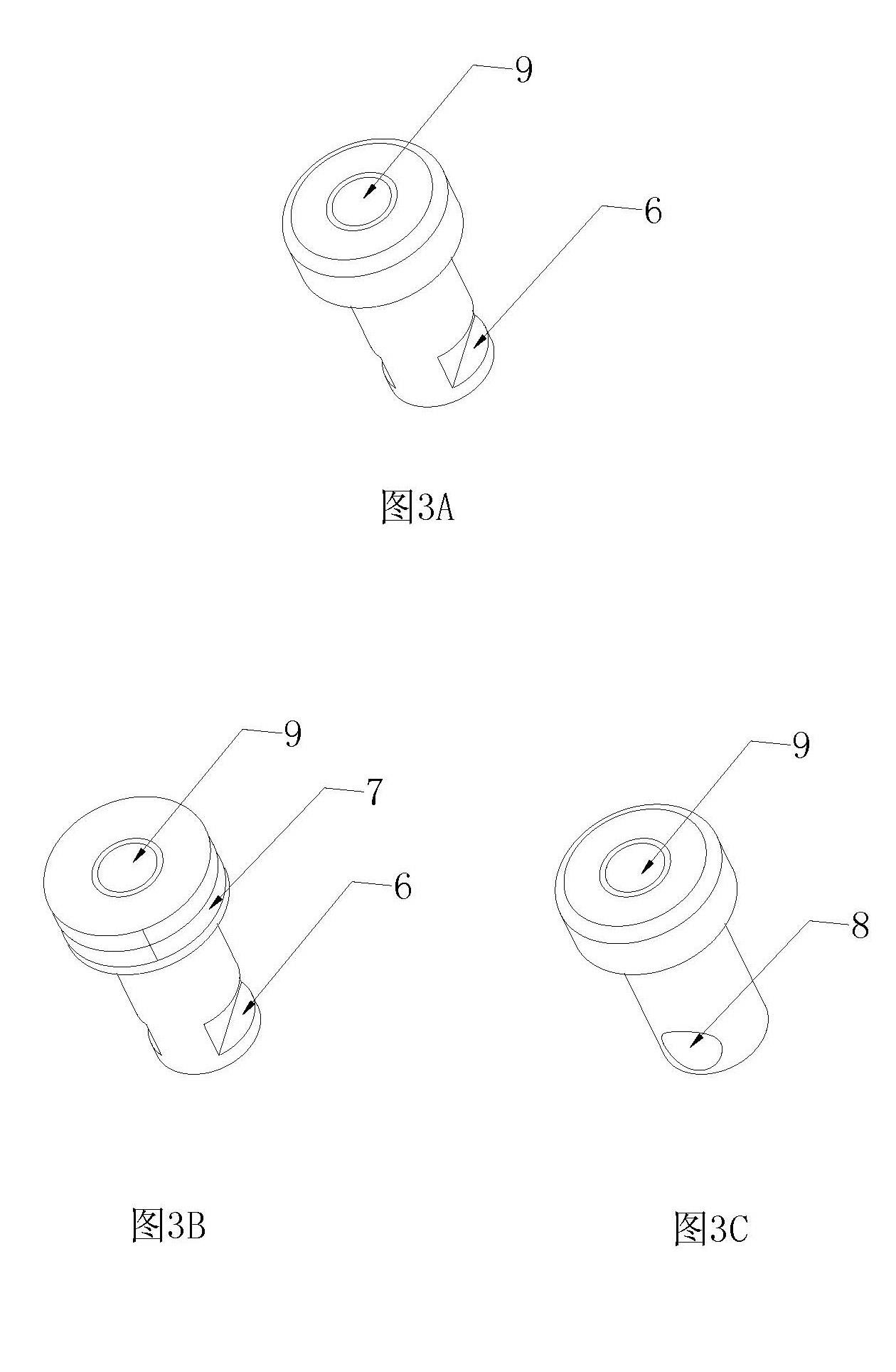

[0051] The 12 poles used in the 12V100Ah storage battery of Embodiment 2 of the present invention are still unified into a pole, such as Figure 4 As shown in A, the pole is composed of two parts: an aluminum insert 27 and a tin-lead alloy 28 containing 3% tin. The upper part of the aluminum insert is equipped with an M6 screw hole 9, and the lower part is provided with a through hole 8. The outer surface of the aluminum insert is first dip-plated with a lead-tin alloy containing 5% tin, and the thickness of the coating is 0.1mm. It is firmly combined with the lead alloy part to ensure that the aluminum insert and the l...

Embodiment 3

[0054] The battery embodiment 3 of the present invention takes a 12V160Ah battery as an example, and the design battery dimensions are 489.5mm in length, 175mm in width and 220mm in height. The material of the battery tank cover is made of ABS resin, and the connection of the tank cover is welded by hot melting method. The specific decomposition is that the height of the battery tank is 195mm, divided into 6 cells, the wall thickness between the cells of the battery tank is 2.5mm, the thickness of the outer wall around the battery tank is 6mm, and the demoulding slope is less than 0.3%. The battery cover is 25mm high, divided into upper and lower parts, the upper part is 15mm high, the lower part is 10mm high, and the middle spacer is 3mm thick. The lower part of the battery cover is divided into 6 cells corresponding to the battery slot, and the wall thickness between the cells is 5mm. The thickness of the outer wall around it is 7mm. The upper part of the battery cover is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com