Composition for organic electroluminescent element, organic thin film, organic electroluminescent element, organic el display device, and organic el lighting

An electroluminescence, organic field technology, applied in organic EL display devices, organic EL lighting. It can solve problems such as the inability to obtain the life of the components, and achieve the effects of uniform organic layer, long-life driving voltage, and excellent film quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

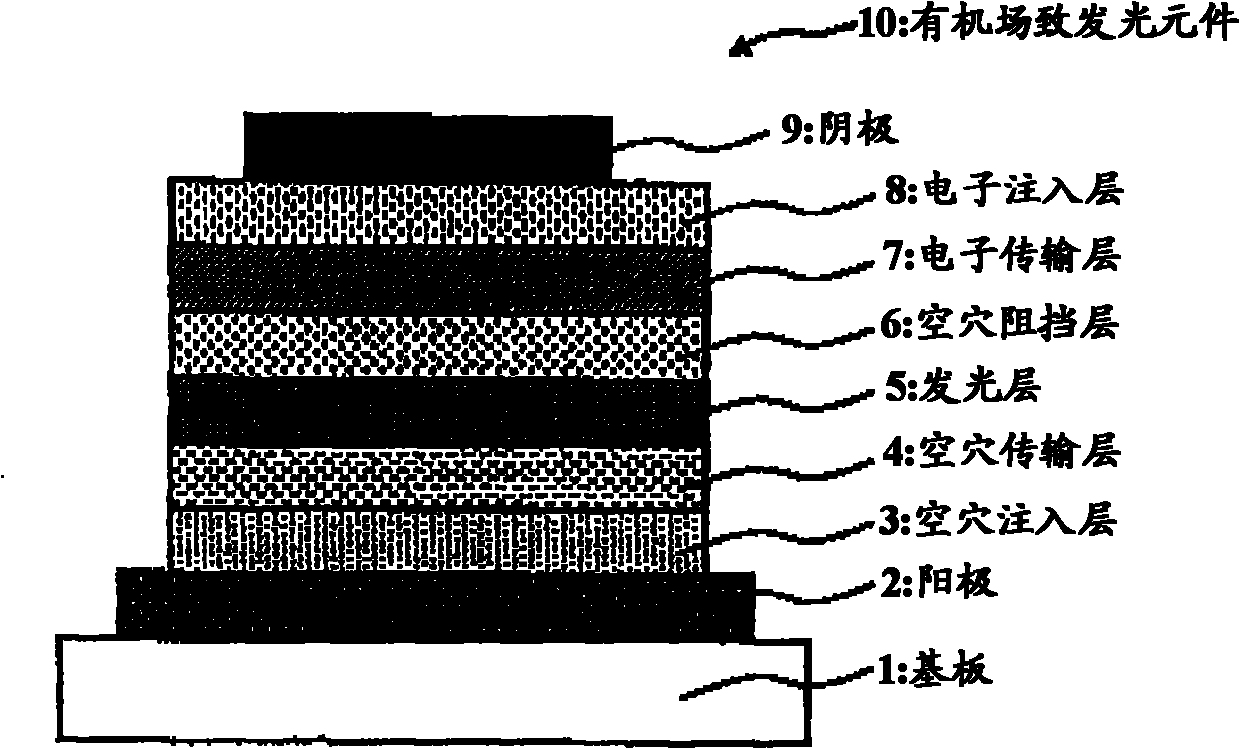

[0459] made figure 1 The organic electroluminescent element shown.

[0460] The anode 2 was formed by patterning a 150 nm-thick indium tin oxide (ITO) transparent conductive film (sputtered film product, sheet resistance 15Ω) formed on a glass substrate into 2 mm-wide stripes using a common photolithography technique. The substrate 1 on which the anode 2 is formed is sequentially subjected to ultrasonic cleaning with acetone, water washing with pure water, and ultrasonic cleaning with isopropanol, then drying with a nitrogen stream, and finally UV ozone cleaning.

[0461] A hole injection layer 3 was formed on the processed substrate as follows.

[0462] As a hole-injecting material, an electron-accepting material having the structure shown below containing aromatic amine-based polymer compound PB-1 (weight-average molecular weight: 29400, number-average molecular weight: 12600) having the following repeating structure was prepared. A positive compound PI-1, and a compositio...

Embodiment 2

[0502] Except that the polymer compound used in the composition for forming a hole transport layer was changed from polymer compound HT-1 to polymer compound HT-2 (weight average molecular weight: 38000, number average molecular weight: 18000), using the light-emitting material (compound D-2) shown in the following structure instead of the light-emitting material (compound D-1) contained in the composition for organic electroluminescent elements used when forming the light-emitting layer 5, and causing light emission The weight ratio of the material (compound D-2) to the charge transport material (compound E-1) is (compound D-2): (compound E-1) = 1: 10, according to the same method as in Example 1 to obtain Organic electroluminescent elements.

[0503] [chemical formula 23]

[0504]

[0505] In addition, the saturation solubility of compound D-2 with respect to cyclohexylbenzene at 20° C. and 1 atmosphere pressure was 2.5 wt %.

[0506] In addition, compound E-1 is the or...

Embodiment 3

[0512] In addition to using the charge transport material (compound E-2) shown in the following structure instead of the charge transport material (compound E-1) contained in the composition for organic electroluminescent elements used when forming the light emitting layer 5, and making the light emitting material The weight ratio of (compound D-2) to charge transport material (compound E-2) is (compound D-2): (compound E-2) = 1: 10, according to the same method as in Example 2 to obtain effective Electroluminescent elements.

[0513] [chemical formula 24]

[0514]

[0515] In addition, since compound E-2 has a solubility of 1.2 wt% relative to cyclohexylbenzene at 20°C and 1 atmosphere, it is difficult to prepare a solution with a concentration of 2.3 wt% at room temperature. Therefore, compound D-2, Compound E-2 and cyclohexylbenzene were mixed, then heated on a hot plate set at 80° C. to dissolve Compound E-2, and used before re-precipitating crystals.

[0516] In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com