Treatment method for recycling coking wastewater and assembled treatment system

A technology for coking wastewater and treatment methods, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of long treatment process, complicated wastewater reuse treatment system, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

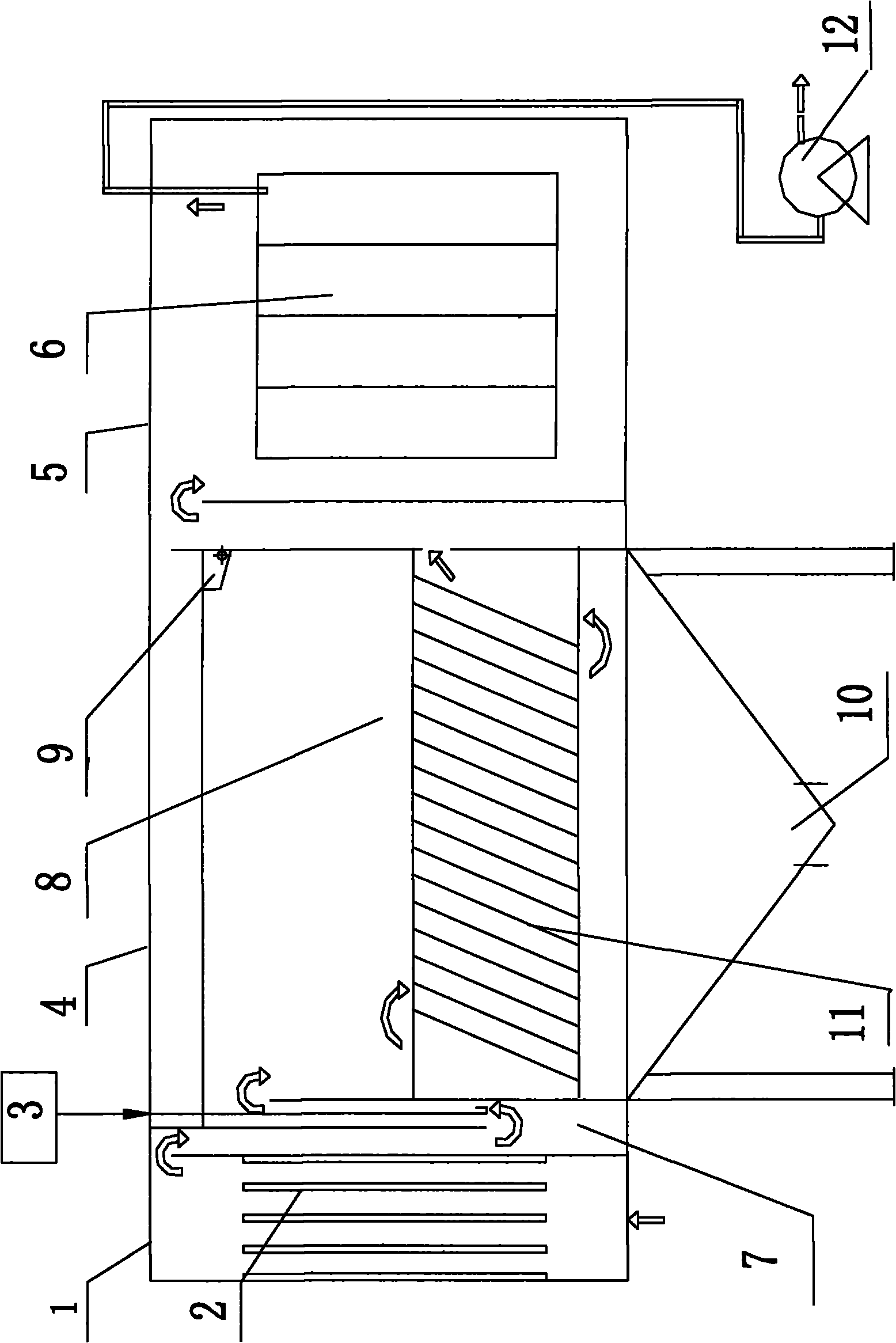

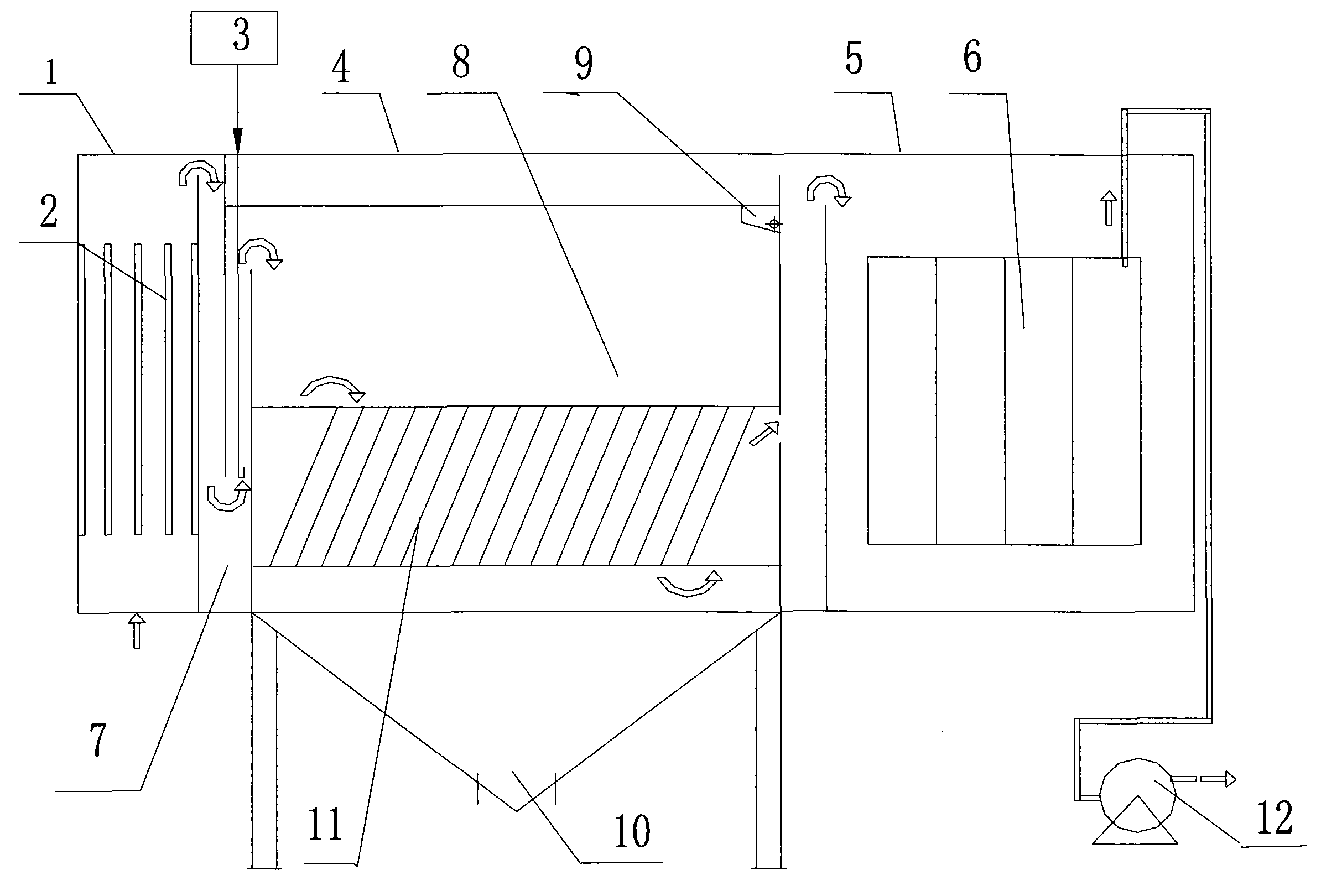

Image

Examples

Embodiment 1

[0061] The COD of coking wastewater raw water after biochemical treatment is 300-600mg / L, NH 3 -N is about 30mg / L, and the chromaticity is 200 times. Dissolved gas pressure is 0.15MPa. The power supply of the electrocoagulation tank adopts 20A ~ 50A high-frequency pulse inverted power supply, the pulse frequency can be operated at 10KHz ~ 50KHz, and the inverted frequency can be operated at 10min.

[0062] After the raw water flows into the electrocoagulation tank from the water inlet at the bottom of the pretreatment device, after staying in the tank for 1 minute, it overflows from the top to the air flotation tank, mixes with dissolved air water and fully contacts. After 15 minutes, the air flotation effluent overflows into the membrane separation tank, and the water is pumped out through the membrane module.

[0063] The membrane module is a submerged microfiltration membrane, and its operating parameters are: the transmembrane pressure difference is controlled below 30kP...

Embodiment 2

[0067] The COD of coking wastewater raw water after biochemical treatment is 300-600mg / L, NH 3 -N is about 30mg / L, and the chromaticity is 200 times. Dissolved gas pressure is 0.15MPa. The power supply of the electrocoagulation tank adopts 20A~50A high-frequency pulse inverted power supply, the pulse frequency can be operated at 10KHz~50KHz, and the inverted frequency can be operated at 5min.

[0068] After the raw water flows into the electrocoagulation tank from the water inlet at the bottom of the pretreatment device, after staying in the tank for 2 minutes, it overflows from the top to the air flotation tank, mixes with dissolved air water and fully contacts. After 20 minutes, the air flotation effluent overflows into the membrane separation tank, and the water is sucked out through the membrane module.

[0069] The membrane module is a submerged ultrafiltration membrane, and its operating parameters are: the transmembrane pressure difference is controlled below 30kPa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com